Method for processing three dimensional spatial structure assembly hole of antenna housing through special drilling rig

A technology of three-dimensional space structure and processing method, which is applied in the processing field of three-dimensional space structure assembly holes of radome special drilling tools, can solve the problems of unguaranteed accuracy, low processing accuracy, and low processing efficiency, and meet product design accuracy requirements, The effect of reducing processing difficulty and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

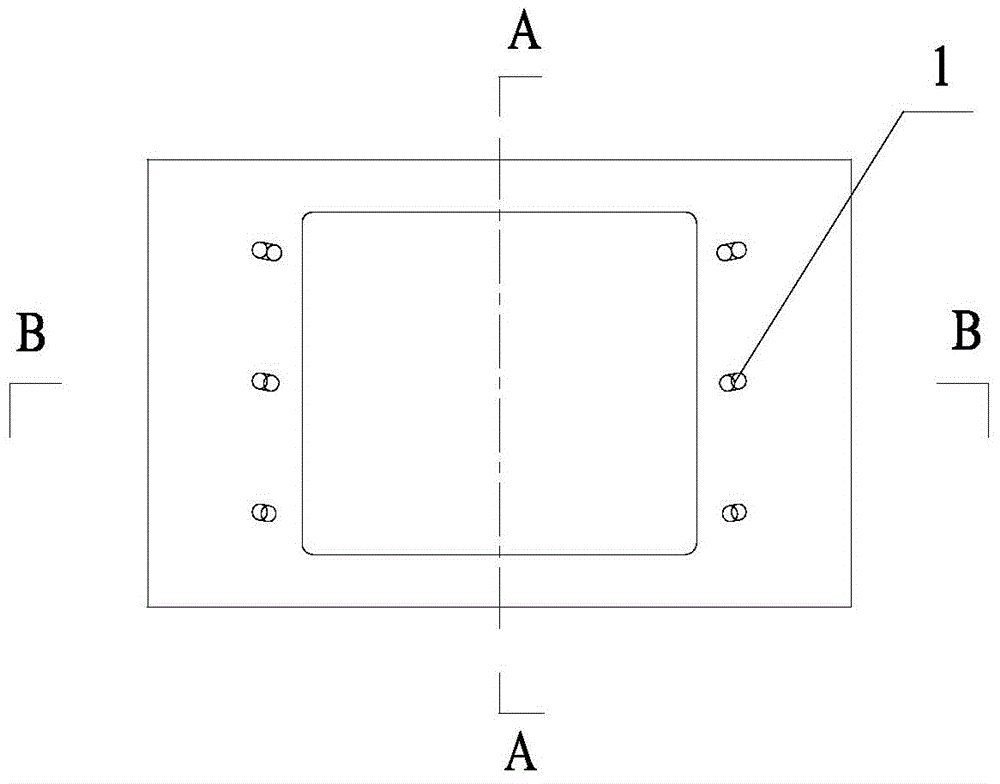

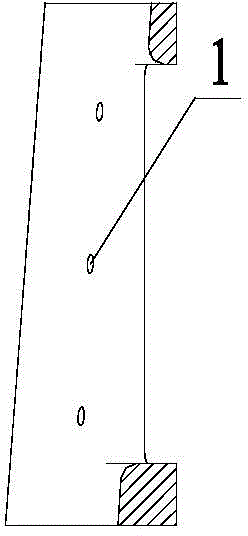

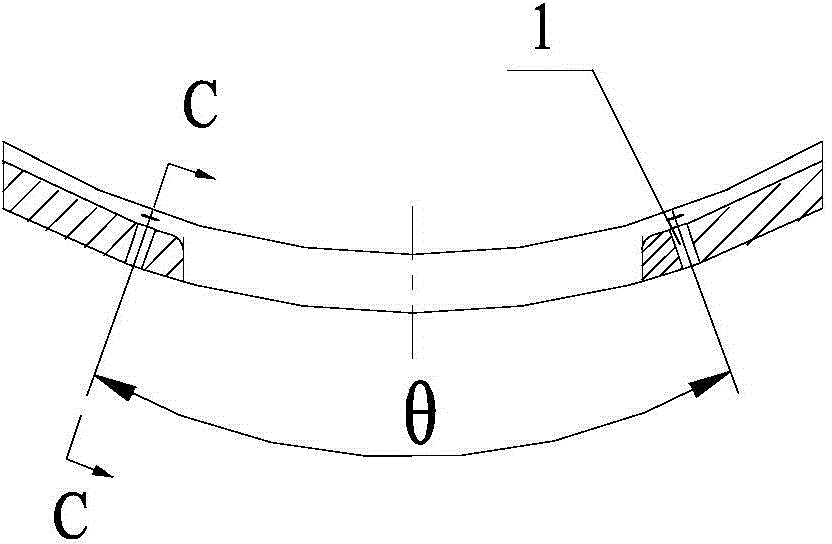

[0031] prepared as figure 1 , combine figure 2 , image 3 , Figure 4 The shown radome special drilling tool three-dimensional space structure assembly hole, its processing method includes the following steps:

[0032] 1) Blank preparation: The blank material is 45# steel, and the square blank is prepared according to the maximum external dimension of the special drilling tool and the machining allowance, and the machining allowance on one side is 5-10mm;

[0033] 2) Milling blank: the six faces of the square blank in milling step 1) are exposed to the light, and the blank is processed by flat grinding to ensure the reference accuracy, and the verticality and parallelism between the six surfaces are all below 0.05mm; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com