Material pressing device of pressing fit mechanism of fully-automatic electric material pressing fit machine

A technology of a pressing device and a pressing machine, which is applied in the field of machinery, can solve the problems of high labor intensity, low production efficiency, high power consumption, etc., and achieve the effects of improving product qualification rate, high equipment safety factor, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

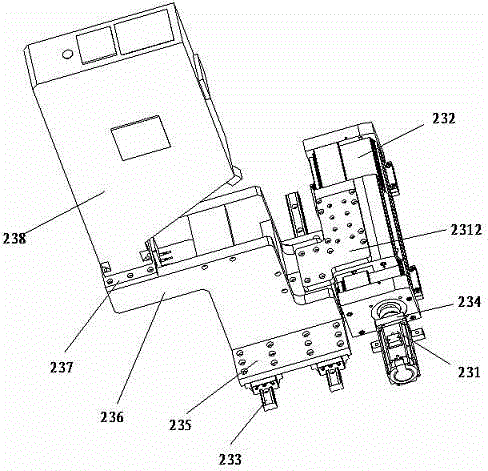

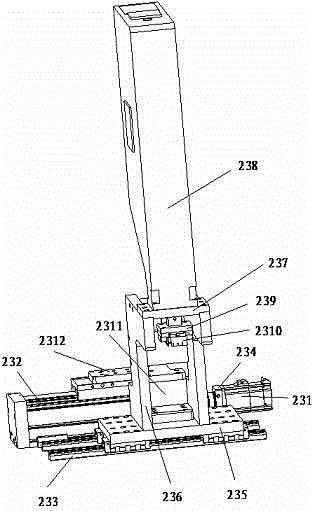

[0009] Such as Figure 1-2 As shown, the pressing device of the pressing mechanism of a fully automatic electric material pressing machine disclosed by the present invention, the pressing device includes a pressing motor 231 fixed to the rack table, a pressing servo slide module 232 And the pressing slide rail 233, the pressing motor 231 is fixed with the frame table through the pressing fixing seat 234, the pressing motor 231 is connected and fixed with the pressing servo slide module 232 through the coupling, and the pressing slide rail 233 is two It is rooted and arranged in parallel with the binder servo slide module 232, and a binder slide 235 is slidably installed on the two binder slide rails 233, and two binder slides 235 are fixedly installed with a "Z"-shaped longitudinal se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap