High-universality feeding device of pipe end-facing machine and feeding method

A flat-head machine and universal technology, applied in metal processing and other directions, can solve the problems of affecting the processing quality of pipe fittings, increasing processing costs, and unable to guarantee pipe fittings, etc., to achieve the effect of reducing processing costs, reducing scrap rate, and high calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

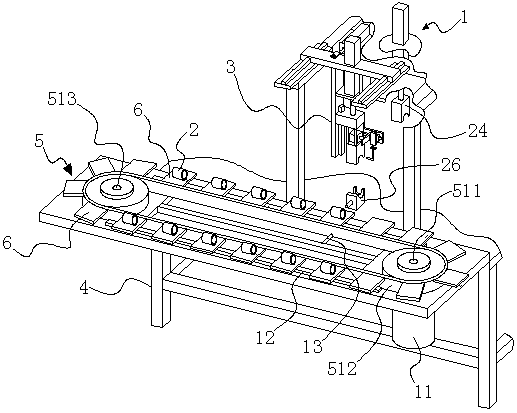

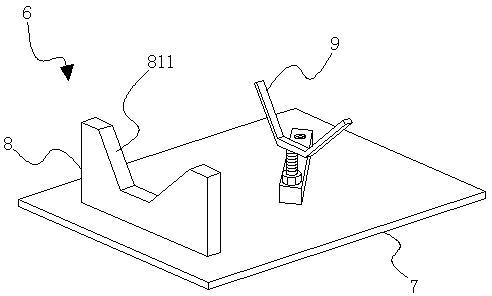

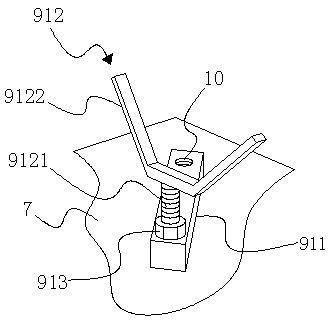

[0063] Embodiment 1: as Figure 1 to Figure 4As shown, a versatile pipe fitting flat head feeding device includes a feeding device located on one side of the flat head machine 1 (not completely shown in the figure) for sequentially sending a plurality of pipe fittings 2 to the feeding position of the flat head machine Mechanism and the manipulator 3 arranged on the flat head machine 1 for sending a plurality of pipe fittings 2 sequentially sent to the feeding position of the flat head machine into the flat head machine for processing, the feeding mechanism includes a feeding frame 4 , the chain conveying mechanism 5 that is arranged on the described feeding frame 4 and a plurality of pipe fitting flat head feeding pallets 6 that are arranged on the described chain conveying mechanism 5 adopt the chain conveying mechanism 5 with a plurality of pipe fitting flat feeding pallets 6 During processing, the worker can place the pipe fittings 2 on all the pipe fitting flat-head feedin...

Embodiment 2

[0091] Embodiment 2: as Figure 18 and Figure 19 As shown, compared with Embodiment 1, the difference is that the structure of the main support block on the pipe fittings flat head feeding pallet in this embodiment is different, that is, a positioning device is provided on one side of the main support block 8 Gasket 27, an axial positioning structure for one end of the pipe fitting is formed between the positioning gasket 27 and the main fork portion 811 of the main support block, and one end of the pipe fitting is placed in the main fork portion 811 of the main support block , the end of one end of the pipe is in contact with the side of the positioning gasket 27 . In this embodiment, the positioning spacer 27 is provided with two pieces, which are all screwed into the outer side of the main support block 8 by screws 28, and the positioning spacer 27 partially exposes the main fork portion 811 of the main support block to utilize The positioning washer 27 and the main fork...

Embodiment 3

[0092] Embodiment 3: Compared with Embodiment 1, the difference is that in this embodiment, the structure of the adjustment through hole 1 on the flat head feeding pallet of the pipe fittings is different, that is, in this embodiment, the adjustment through hole 1 is set Long strip-shaped through holes, such as waist-shaped holes. In this way, when the other end of the adjustment block 1 is rotated with one end of the adjustment block 1 as the center, the center of rotation can change along the elongated hole, which increases the adjustable range and further increases the versatility of this embodiment .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com