Mechanical grab

A mechanical gripper and body technology, applied in the field of mechanical grippers, can solve the problems of uneven force, unsteady grasping of workpieces, and easy occurrence of safety accidents, and achieve the effect of uniform force and firm grasping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

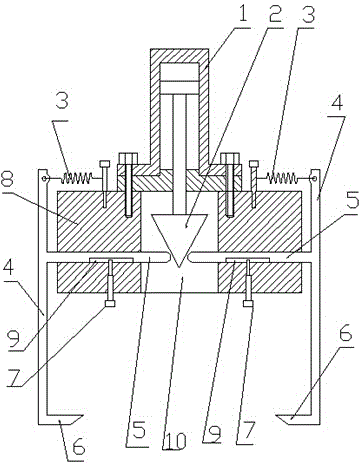

[0009] The described mechanical gripper comprises a piston cylinder (1), a spreader body (8), the spreader body (8) is a circle or a regular polygon, and the center of the body (8) has a A large through hole (10), the piston cylinder (1) is installed and fixed at a position just above the large through hole (10) of the spreader body (8), and the piston rod of the piston cylinder (1) is placed in the through hole (10) Inside, an inverted cone (2) is fixed on the piston rod of the piston cylinder (1), and two or more through holes uniformly distributed in the circumferential direction are formed in the circumferential diameter direction of the spreader body (8). A guide rod (5) is arranged in each through hole, the guide rod (5) is provided with a guide groove (9), and the head of the guide pin (7) installed on the spreader body (8) lies on into the groove (9), a moving arm (4) is fixed at the outer end of each guide rod (5), the moving arm (4) is parallel to the center li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com