A kind of milk powder grid and preparation method thereof

A production method and technology of milk powder, applied to rigid containers, packaging, containers, etc., can solve the problems of rough surface, single structure, inconvenient use, etc., and achieve the effect of unique shape, round hand feeling, and moisture prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

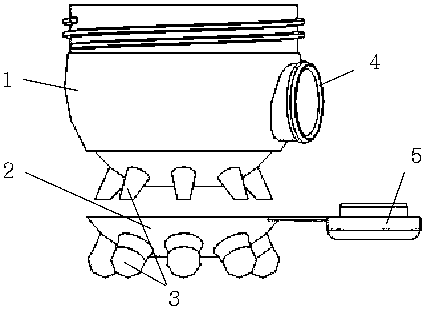

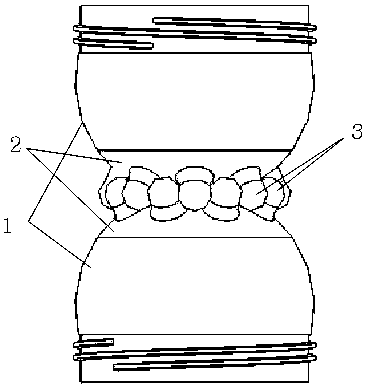

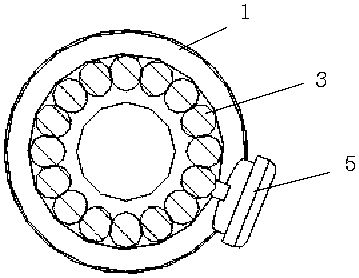

[0023] Refer below figure 1 , figure 2 and image 3 The present invention will be described in detail.

[0024] Make a milk powder box with 8 feet by imitating the characteristics of an octopus. The milk powder box includes a cup-shaped container 1 and a top cover screwed to the top of the container. The container 1 of the milk powder box has a smooth inner surface , the outside of the container body 1 is fixed with an elastic outer packaging layer 2, and the container body 1 and the outer packaging layer 2 are made into a whole using a rubber-covering process, and eight supporting feet 3 are arranged at the bottom of the container body 1; through secondary injection molding The encapsulation process firmly attaches the outer packaging layer 2 to the outside of the receiving body 1, and the outer packaging layer at the bottom of the supporting feet 3 is in the shape of a ball head.

[0025] Material selection: the container 1 is made of PP material, and the outer packaging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com