Rope rolling rack, mountable and demountable gantry crane, and loading and unloading method

A technology for installing gantry cranes and rope roll racks, which is used in transportation and packaging, trolley cranes, load hanging components, etc., can solve the problems of short service life of rope roll racks, large frame moment and difficulty, and save energy. , The rising and falling process is stable and the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

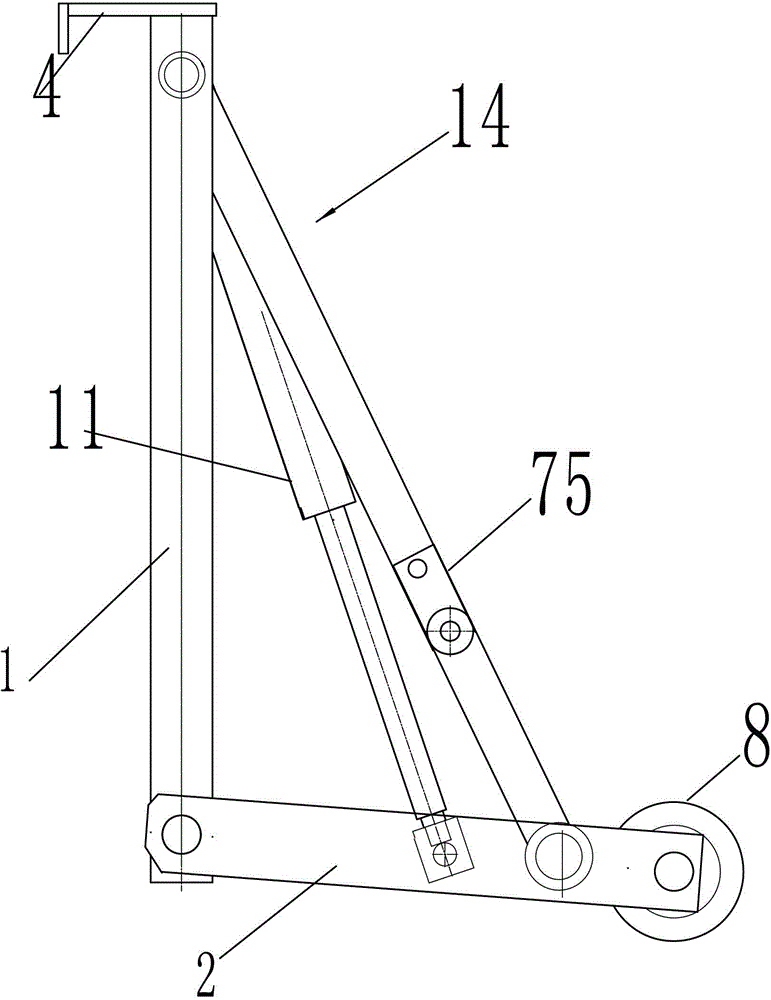

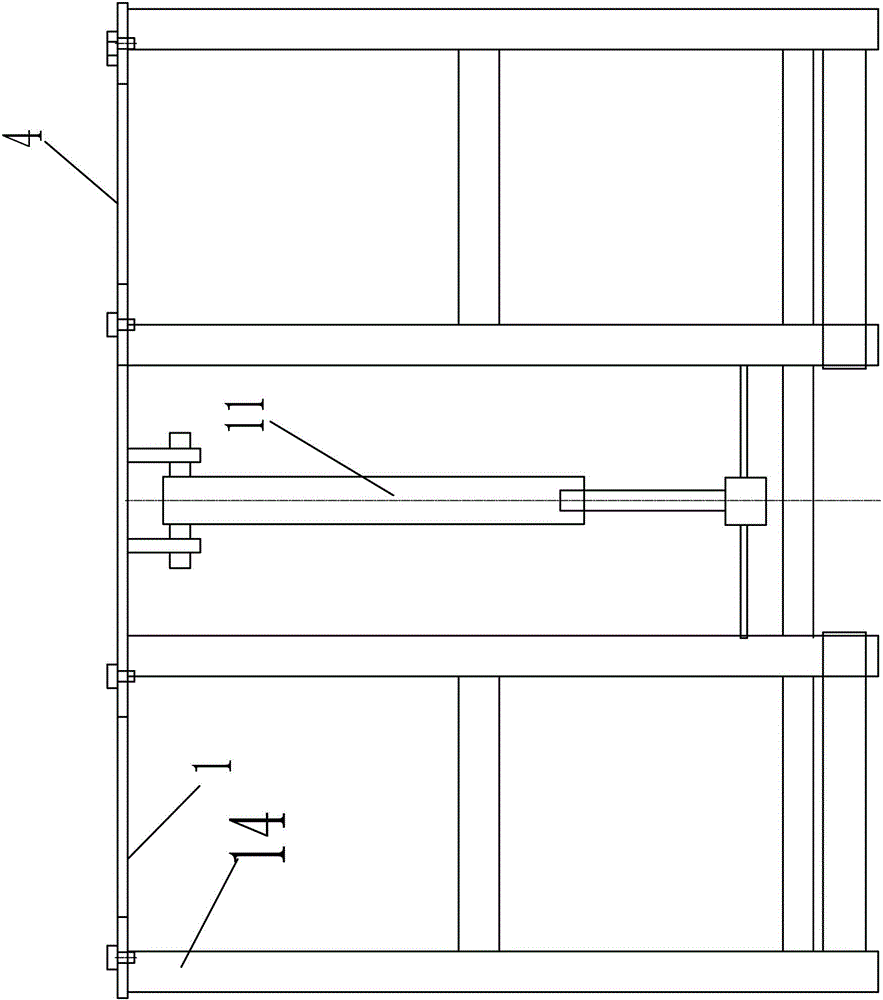

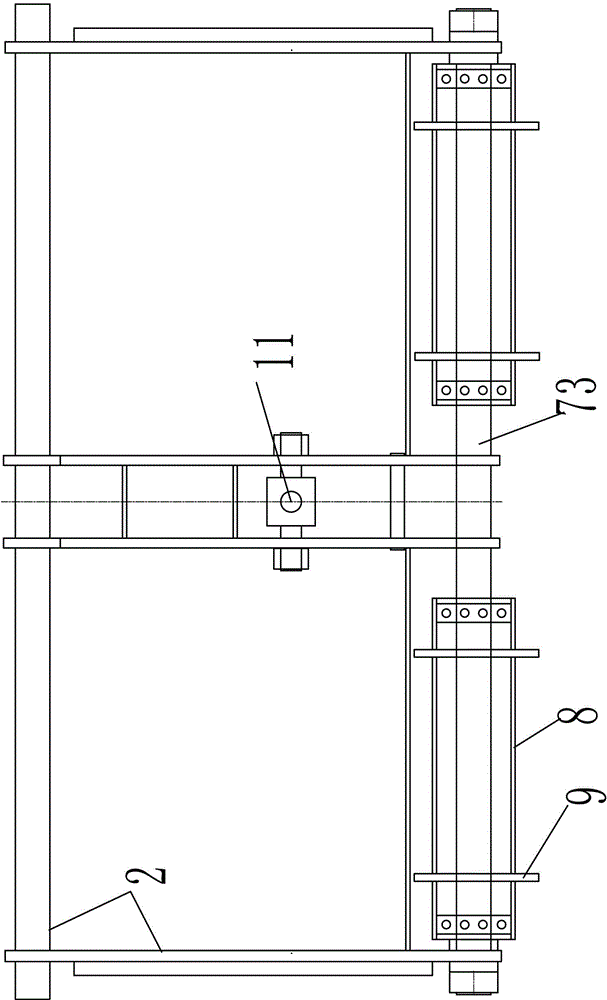

[0087] A rope roller frame, such as Figure 4-5 As shown, it includes a bottom frame 2 and a stand 1 mounted on the bottom frame 2; the top of the stand 1 is provided with a hook horizontal side 4, and one end of the bottom frame 2 is equipped with a rotating shaft 73, which is set on the rotating shaft 73 There is a drum 8 with a retaining rope ring 9; the underframe 2 is fixedly connected with the stand 1, and a horizontal telescopic oil cylinder 11 and a telescopic sleeve 71 are arranged between the underframe 2 and the rotating shaft 73. The bottom frame 2 is provided with a travel switch that triggers the movement of the telescopic oil cylinder 11 . Both sides of the telescopic oil cylinder 11 are provided with telescopic sleeves 71 connecting the underframe 2 and the rotating shaft 73 as auxiliary support members; the telescopic sleeves 71 are provided with stoppers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com