Energy-saving stirring drilling machine

A technology for stirring drilling rigs and stirring rods, which can be used in drill rods, drill pipes, drilling equipment, etc., and can solve problems such as energy waste and large configuration power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

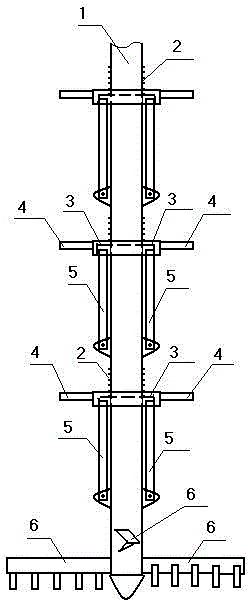

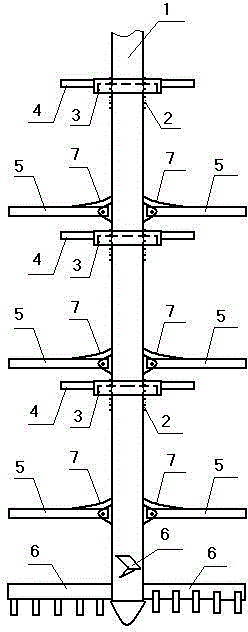

[0012] Accompanying drawing is a kind of specific embodiment of the present invention, and this embodiment drilling rod 1 lower end is equipped with drilling bit 6, and drilling bit top is equipped with many groups of long stirring rods 5, and each long stirring rod lower end is hinged on drilling rod, The upper part of each group of long stirring rods is provided with a screw cap, and a short stirring rod 4 is respectively fixed on the left and right sides of each screw cap 3. On the drill pipe, the other end is fixed to the long stirring rod; when drilling down, the upper end of each long stirring rod is gathered in the screw cap, and when the drill is lifted, each long stirring rod is in a horizontal state.

[0013] When the drill rod is drilled in the present invention, the drill rod drives the drill bit to rotate forward. Due to the reaction force of the soil on the short stirring rod, the short stirring rod reversely twists the screw cap, and the screw cap moves downward,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com