Prefabricated pump station base

A pumping station and double-bottom technology, which is applied to waterway systems, drainage structures, water supply devices, etc., can solve the problems of small volume of prefabricated pumping stations and small flow of transported fluid, and achieve novel structures, reduce sedimentation, and enhance connection strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

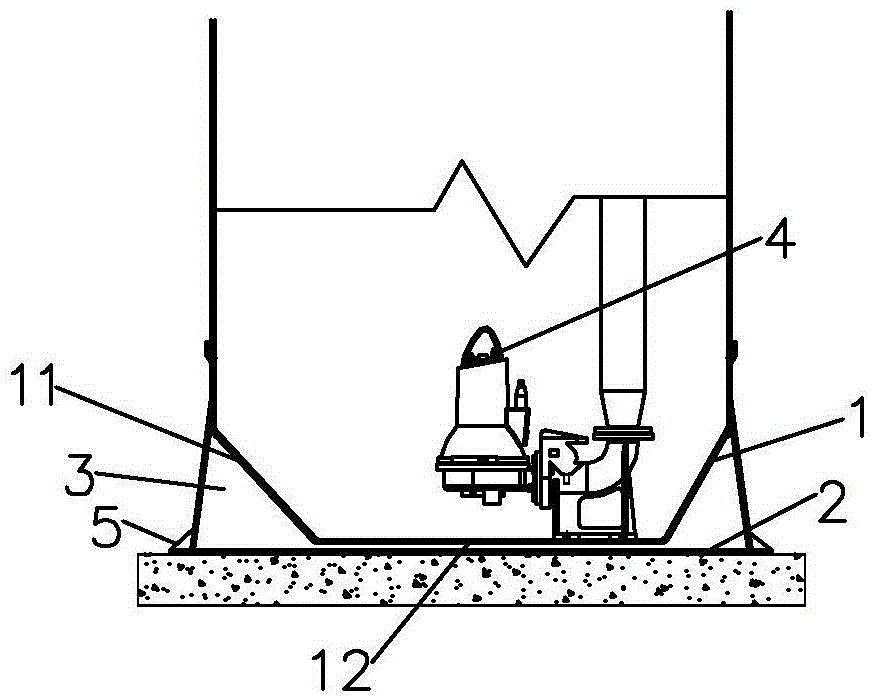

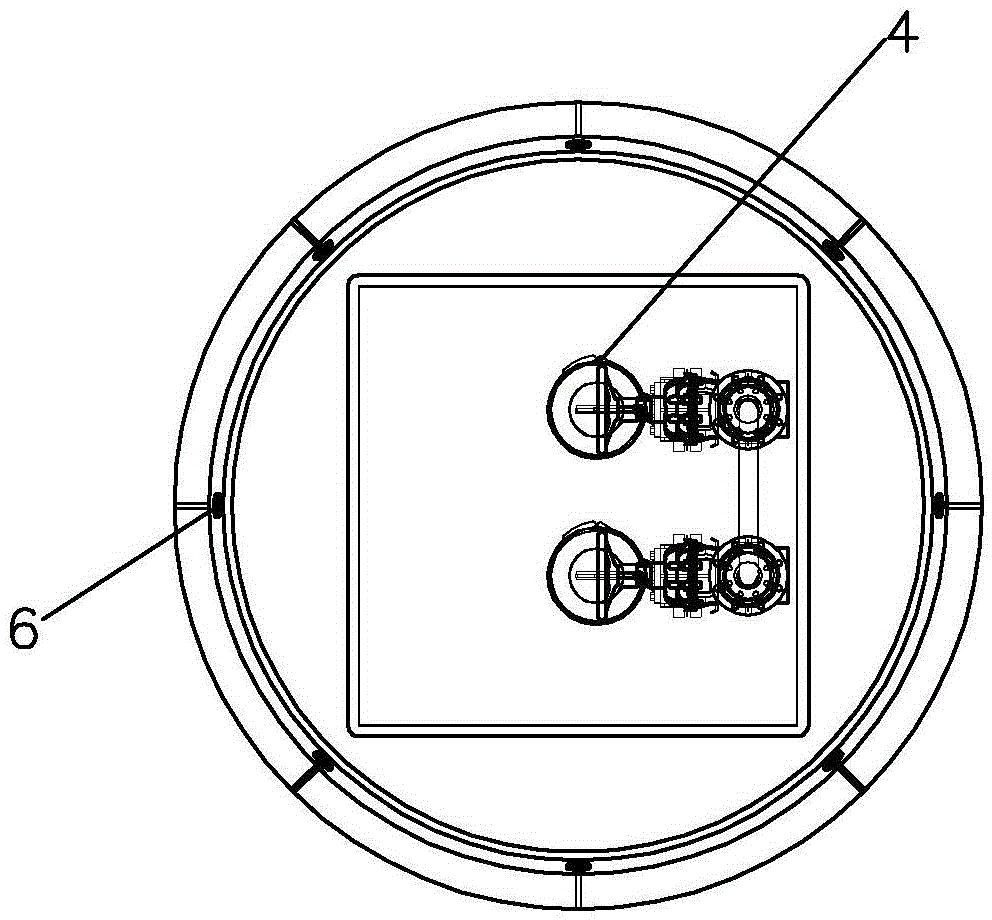

[0022] as attached figure 1 to attach figure 2 As shown, the base of the prefabricated pumping station of the present invention is a double bottom structure, including the upper bottom 1 located above, the lower bottom 2 located below the upper bottom 1 and connected to the upper part of the upper bottom 1, the upper bottom 1 and the lower bottom 2 The double bottom is provided with a hollow part 3 for accommodating fillers, and a grouting hole 6 for pouring fillers into the hollow part 3 is provided on the double bottom. The horizontal part 12 connected to the bottom end of the upper floor 1 and the lower floor 2 is provided with reinforcing ribs 5 for reinforcement.

[0023] In this embodiment, the surface of the extension part 11 is a plane, the horizontal part 12 is a square shape, and the submersible sewage pump 4 is arranged in the square area and along one side of the square.

Embodiment 2

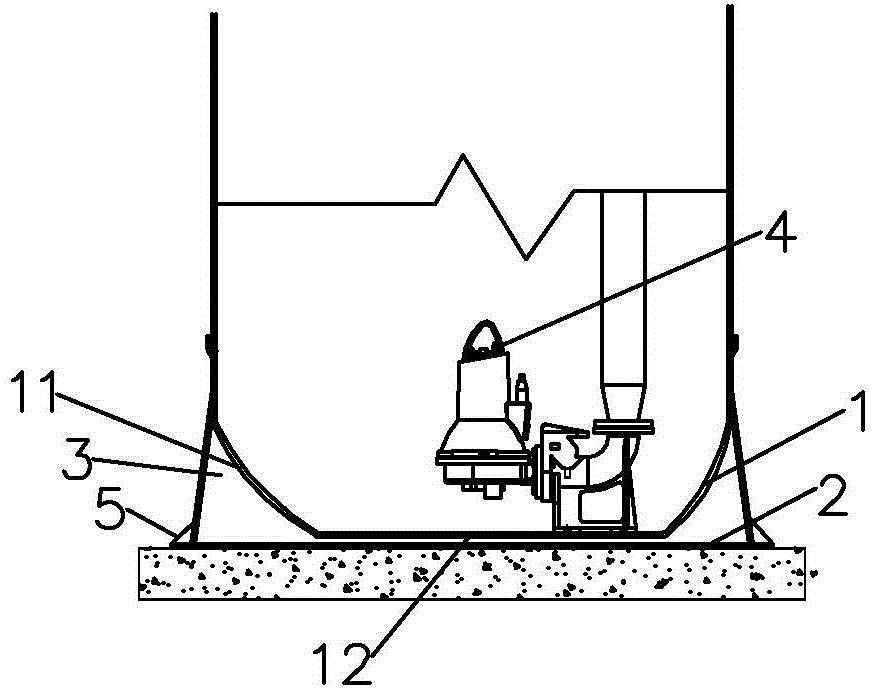

[0025] as attached image 3 As shown, the base of the prefabricated pumping station of the present invention is a double bottom structure, including the upper bottom 1 located above, the lower bottom 2 located below the upper bottom 1 and connected to the upper part of the upper bottom 1, the upper bottom 1 and the lower bottom 2 The double bottom is provided with a hollow part 3 for accommodating fillers, a grouting hole 6 (not shown in the figure) for pouring fillers into the hollow part 3 is provided on the double bottom, and the upper bottom 1 includes an extension extending downward and inward. Part 11, a horizontal part 12 connected to the bottom end of the extension part 11, and a reinforcing rib 5 with a reinforcing effect is provided at the junction of the upper bottom 1 and the lower bottom 2.

[0026] In this embodiment, the surface of the extension part 11 is a curved surface protruding outward, the horizontal part 12 is in the shape of a square, and the submer...

Embodiment 3

[0028] as attached Figure 4 As shown, the base of the prefabricated pumping station of the present invention is a double bottom structure, including the upper bottom 1 located above, the lower bottom 2 located below the upper bottom 1 and connected to the upper part of the upper bottom 1, the upper bottom 1 and the lower bottom 2 The double bottom is provided with a hollow part 3 for accommodating fillers, and a grouting hole 6 for pouring fillers into the hollow part 3 is provided on the double bottom. The horizontal part 12 connected to the bottom end of the upper floor 1 and the lower floor 2 is provided with reinforcing ribs 5 for reinforcement.

[0029] In this embodiment, the surface of the extension part 11 is a plane, the horizontal part 12 is a combined shape of a semicircle and a rectangle, the long side of the rectangle is the diameter of the semicircle, and the submersible sewage pump 4 is arranged in the rectangular area. And set along the long side of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com