Formwork supporting structure of dismounting-free external wall formwork

A formwork and exterior wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems that the bolt holes cannot reach the original fair-faced concrete, reduce the construction efficiency, increase the construction steps and quality control links, etc. The effect of working efficiency, reducing working intensity and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

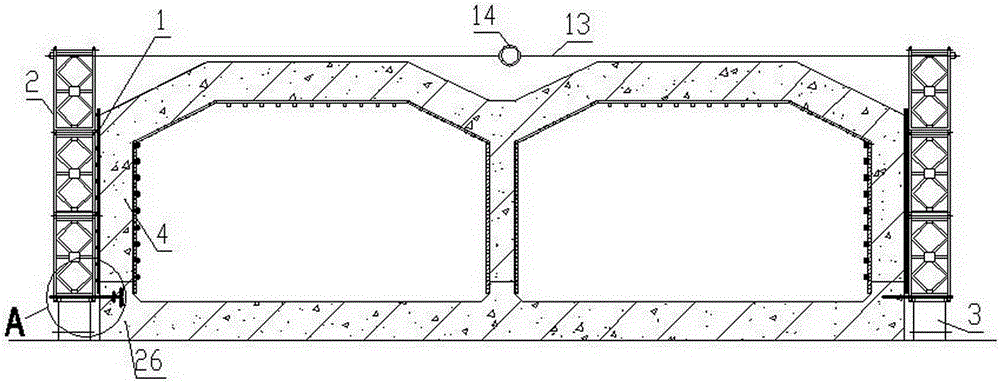

[0030] This embodiment and drawings illustrate the present invention by taking the construction of the outer wall of the tunnel as an example.

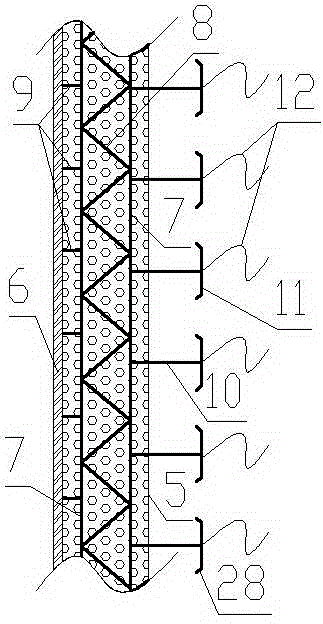

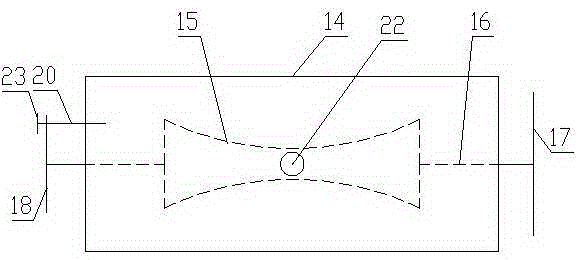

[0031] Such as Figure 1 to Figure 9 As shown, the formwork support structure of the external wall formwork without disassembly of the present invention includes two rows of outer wall formwork 1, two rows of formwork positioning devices 2, two bases 3, an upper pressing device and a lower pressing device.

[0032] The template positioning device 2 is arranged on the outer side of the exterior walls 4 on both sides of the building and is connected to the exterior wall template 1. The bottom end of each template positioning device 2 is respectively connected to one of the bases 3; the two rows of exterior wall templates 1 The top of the building is higher than the outer wall of the building and the upper pressing device is connected between the two; the lower pressing device is connected between the each template positioning device 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com