An adaptive double gas source gas heater

An adaptive, dual gas source technology, applied to gas fuel burners, burners, applications, etc., can solve problems such as heater load rise, and achieve the effect of eliminating the risk of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

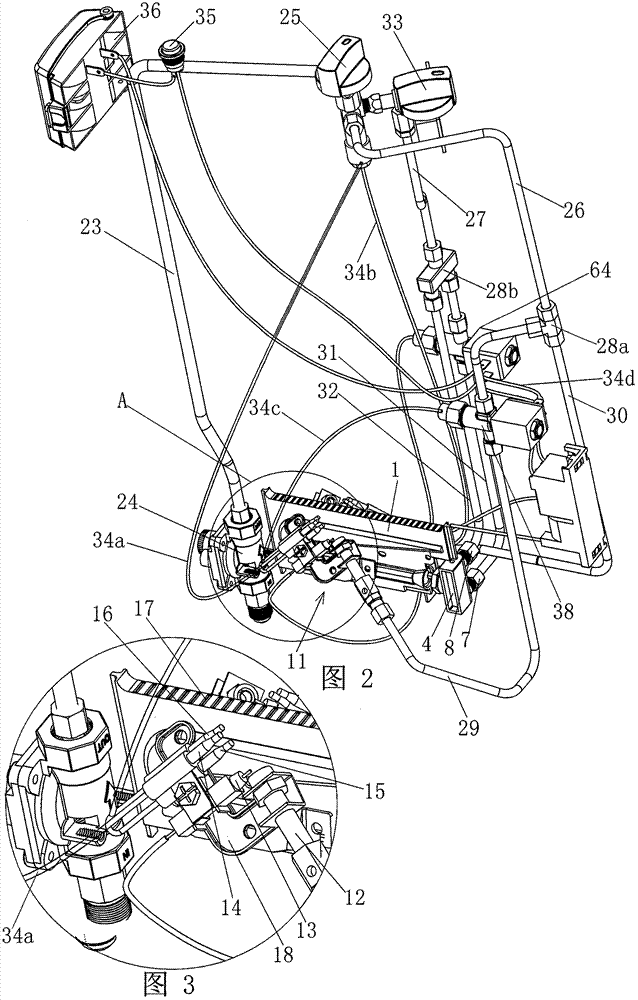

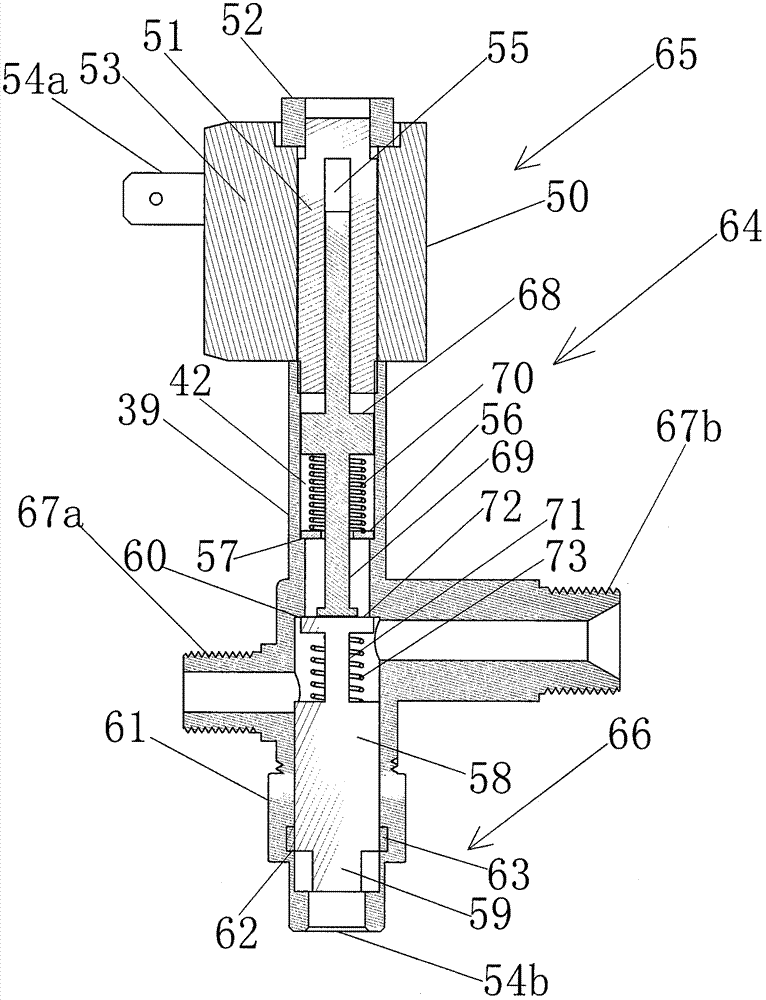

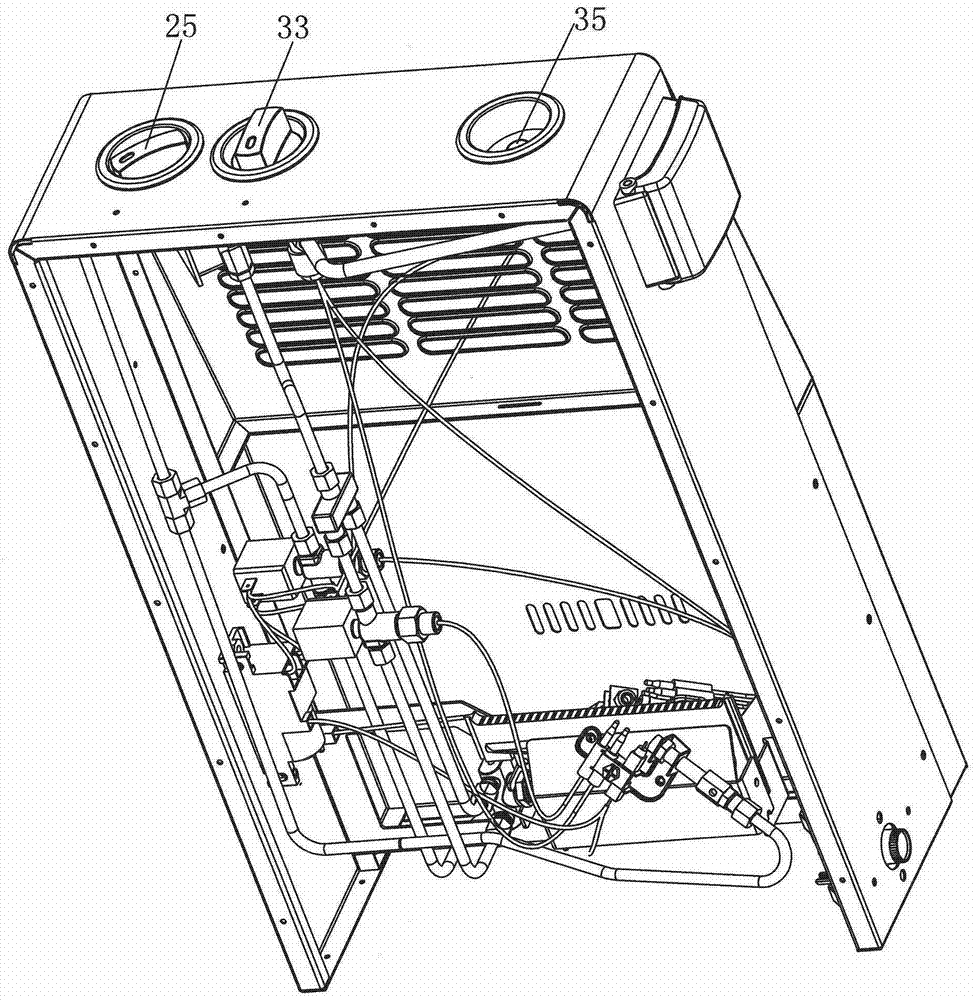

[0047] Embodiment: a kind of self-adaptive double gas source gas heater, such as Figure 1-13 As shown, the following components are included:

[0048] Burner 1, such as Figures 10-13 As shown, the burner 1 is a combustion fire row, and the burner 1 is provided with a circuitously arranged air passage 2, and one end of the burner 1 is provided with a trumpet-shaped air inlet 3, and a nozzle 4 is arranged beside the air inlet 3, The nozzle 4 has a first nozzle 5 and a second nozzle 6 adapted to natural gas and liquefied gas respectively, and a first interface 7 and a second interface 8 connected to the first nozzle 5 and the second nozzle 6 respectively. 7. The second interface 8 has external threads to facilitate connection with the air supply pipeline; a first air passage 9 connecting the first interface 7 and the first nozzle 5 is provided in the nozzle 4, and the second interface 8 is connected to the second The second air channel 10 of the nozzle 6, the first air channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com