Multi-dimensional force/torque sensor

A torque sensor and multi-dimensional force technology, which is applied in the direction of instruments, force measurement, torque measurement, etc., can solve the problems of large device volume, complicated manufacturing process, and low force accuracy, and achieve accurate measurement, small overall volume, and production cost savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

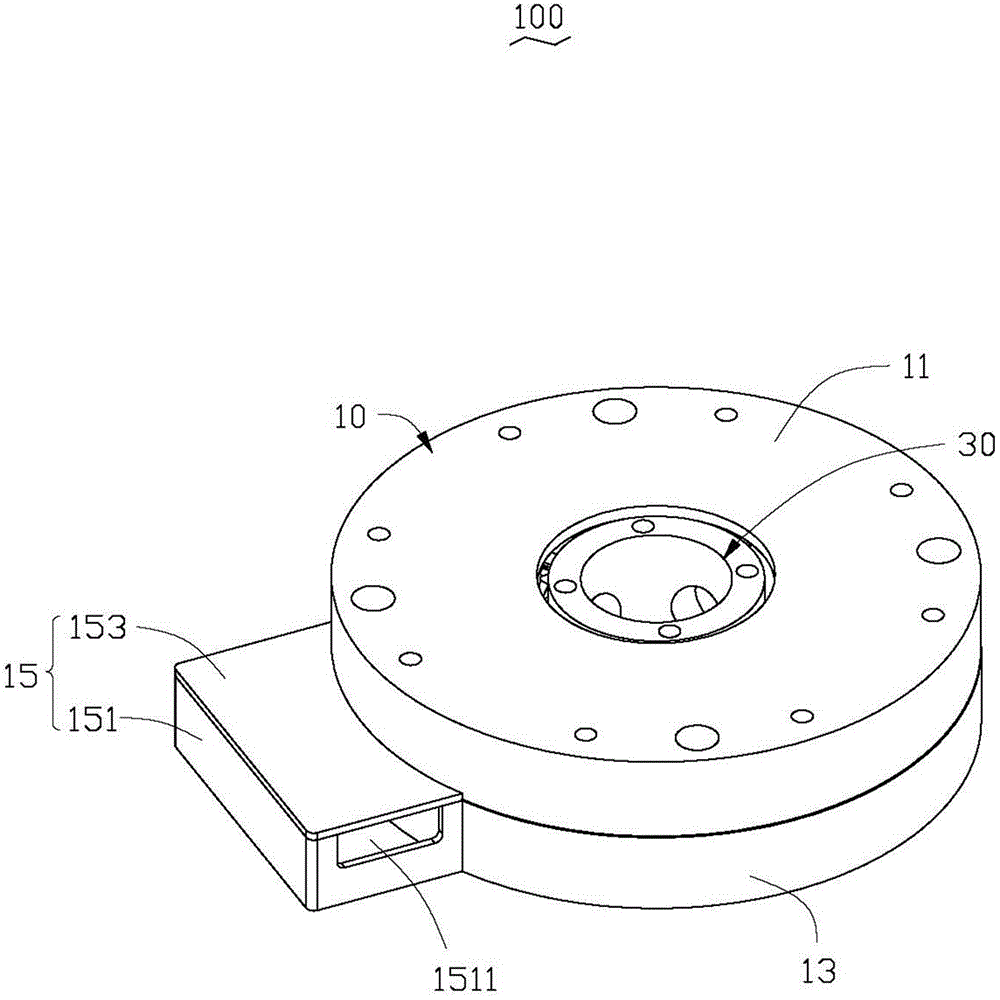

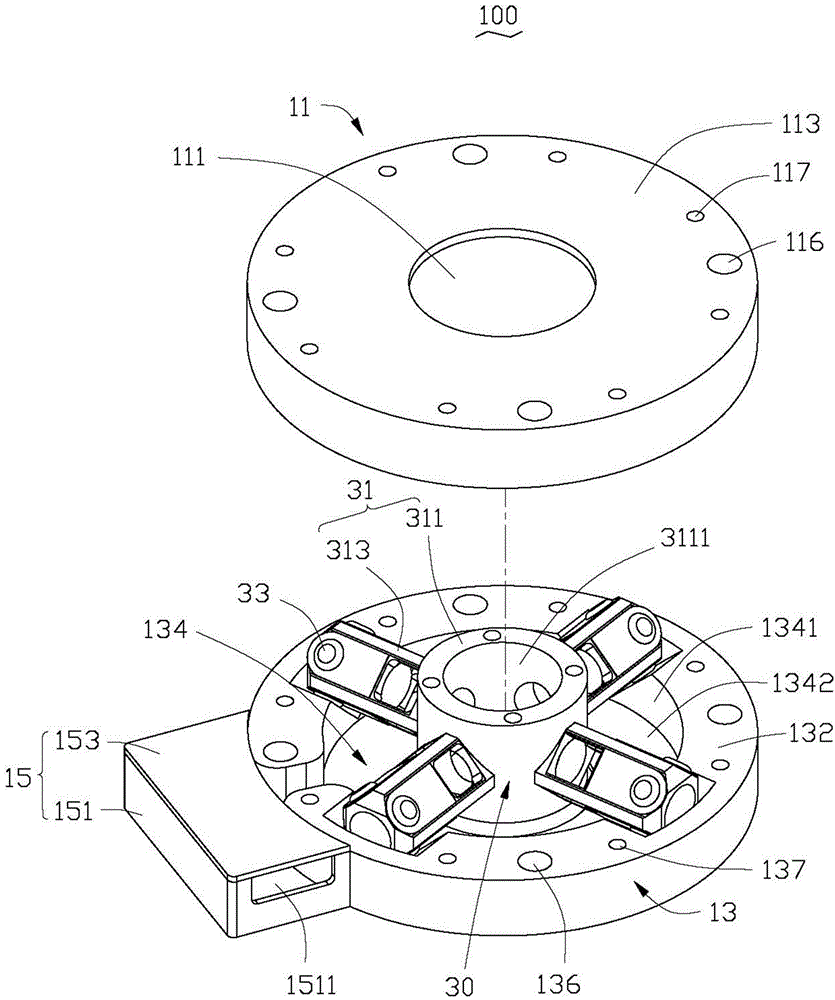

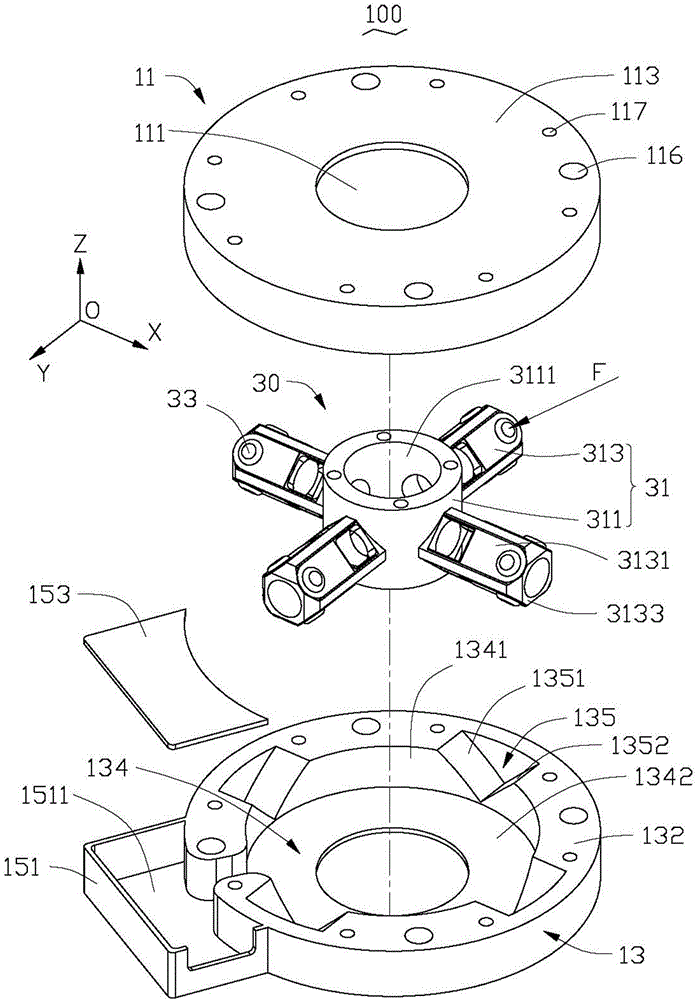

[0015] see figure 1 and figure 2 , the multi-dimensional force / torque sensor 100 in this embodiment is used to be fixed on the manipulator, so as to sense the force / torque applied by the execution end of the manipulator when assembling or processing the workpiece. The multi-dimensional force / torque sensor 100 includes a mounting component 10 and a conducting component 30 . The conduction component 30 is accommodated in the installation component 10 .

[0016] Please also see image 3 and Figure 4 1. The mounting assembly 10 includes an upper cover 11 and a lower cover 13 which are similar in structure and fixed together, and an accommodating part 15 fixed on the outer circumference of the lower cover 13 . The upper cover 11 is roughly disc-shaped. A through hole 111 is defined through the upper cover 11 along the axial direction thereof. The upper cover 11 includes a first end surface 112 and a second end surface 113 parallel to and opposite to the first end surface 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com