Deviation Correction Method of Flying Probe Tester

A technology of flying probe testing machine and calibration method, which is applied in the direction of electronic circuit testing, etc., can solve the problems of poor accuracy of flying probe testing, and achieve the effect of fast process, high efficiency, and improved calibration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

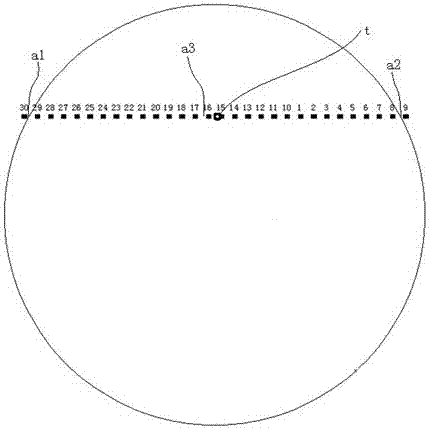

[0031] The positive and negative directions of the X direction mentioned in the present invention, as well as the forward and reverse directions of the Y direction, use the cross target of the camera image as the coordinate axis, and the positive and negative directions of the X axis correspond to the positive and negative directions of the X direction. The positive and negative directions of the Y axis correspond to the positive and negative directions of the Y direction.

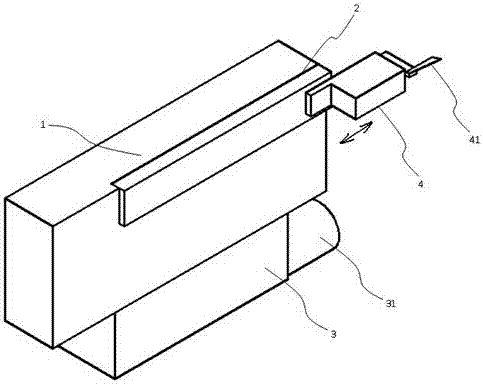

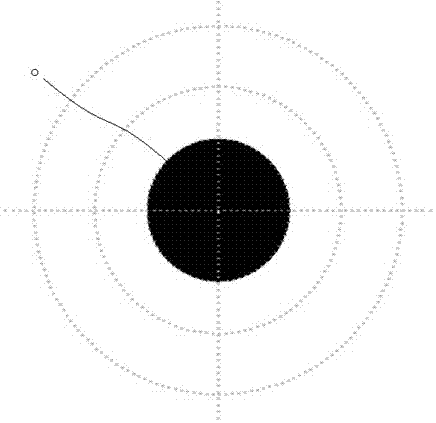

[0032] figure 1 In order to apply the test arm of the flying probe testing machine of the deviation correction method of the present invention, the above-mentioned test arm includes a main body 1, a Z-axis guide rail provided on the main body 1, and a probe device 4 movably installed on the Z-axis guide rail. The front end of the probe device 4 is provided with a probe 41 along the Z-axis direction, and a camera 3 is fixed on the underside of the main body, wherein the camera lens 31 is arranged along the ...

Embodiment 2

[0044] This embodiment adds the following process on the basis of step (4) of embodiment 1: after the control system compensates the above-mentioned actual deviation value, the center of the cross target of the camera image is aligned with the center of another test point of the PCB board to be calibrated o , the area of the test point is smaller than the area of the test point in step (1), repeat step (2) and step (3), and obtain a more accurate actual offset after detecting the center o of the test point through a smaller step size After the control system compensates the above actual offset again, the test is carried out. By adding the above steps, the error can be further reduced to a minimum value, ensuring that the alignment point of the camera is highly coincident with the actual needle insertion point of the probe, and the test accuracy is ensured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com