Building element tester calibrating device and calibrating method thereof

A technology for verification devices and building components, which is applied in the testing of machines/structural components, measuring devices, testing of mechanical components, etc., can solve the problems of complex verification process, influence of verification accuracy, loose cooperation, etc., to reduce complexity, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

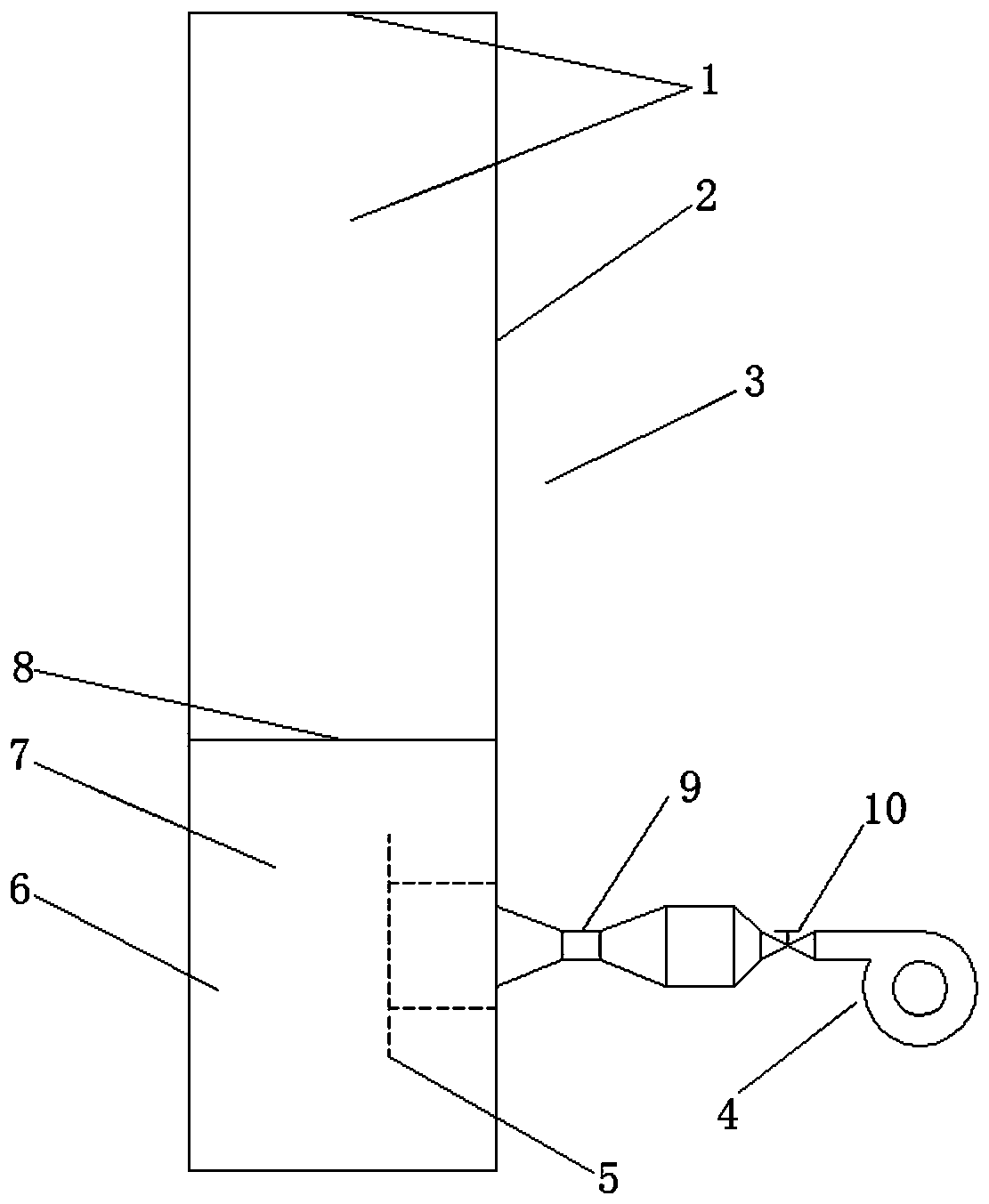

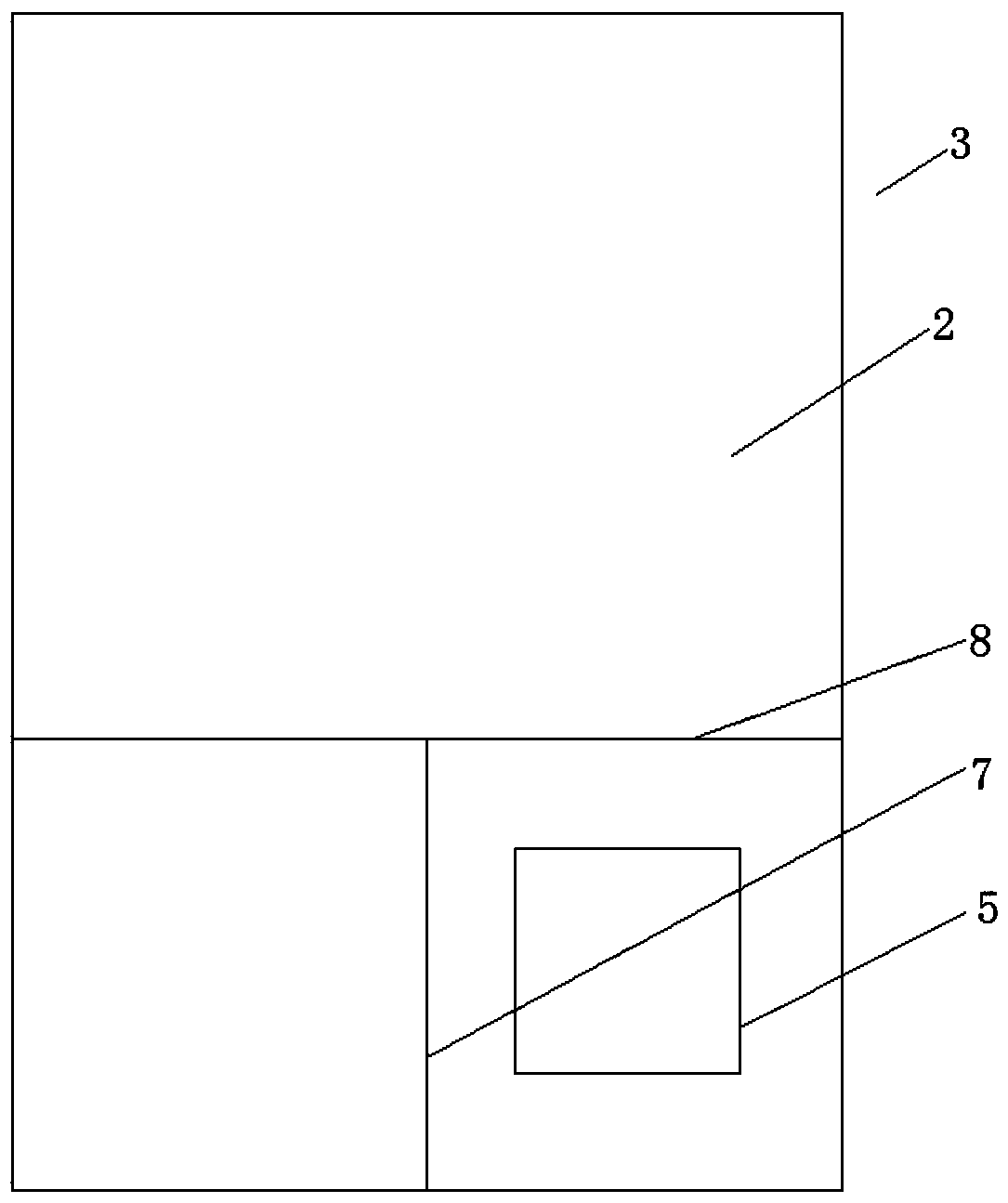

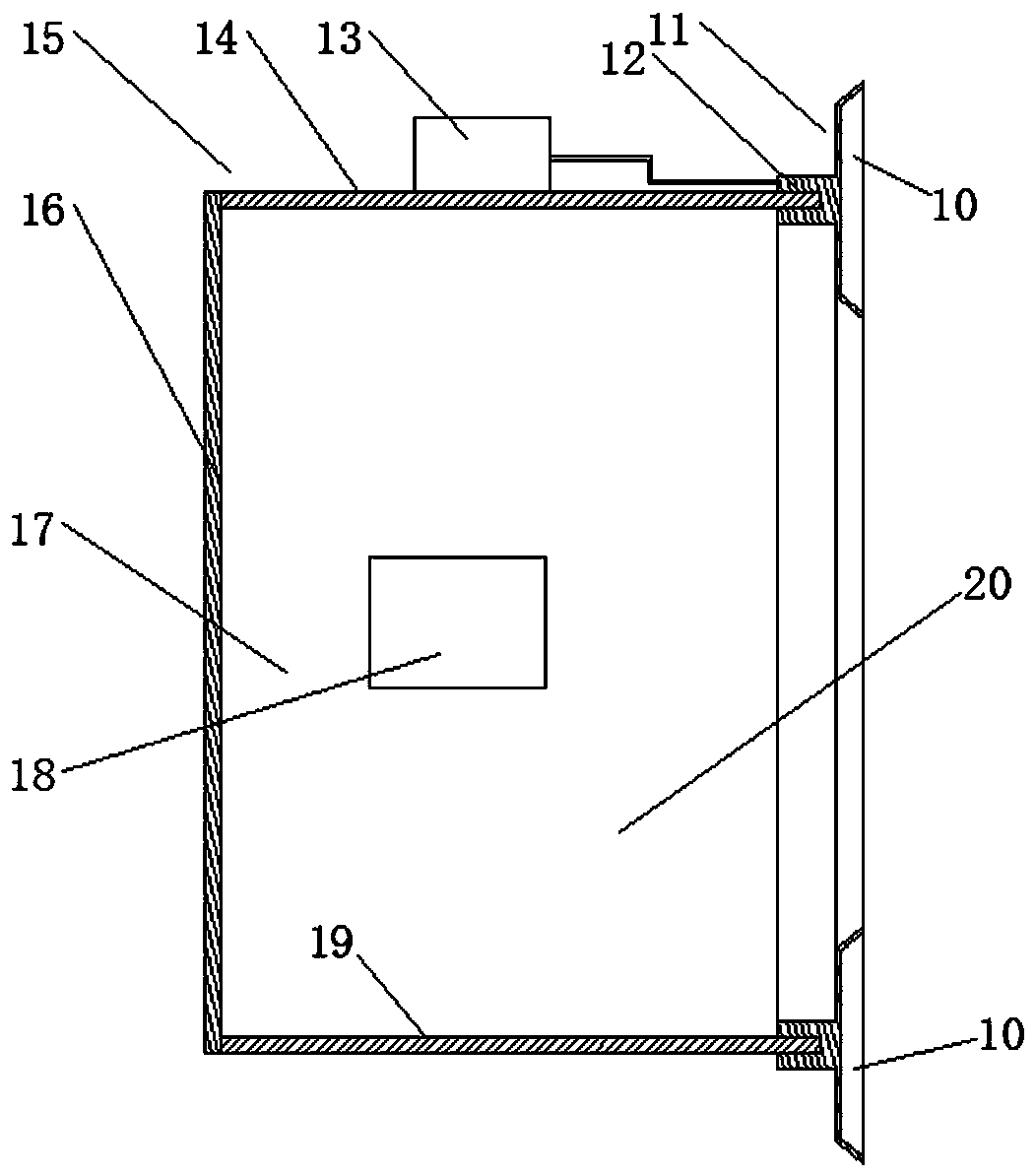

[0021] An example of a verification device for a building component testing machine Figure 3~5 As shown: it includes the verification device frame 15 which is used to cover the periphery of the corresponding air inlet baffle when in use. The verification device frame includes a frame bottom plate 16 and surrounding frame side plates, and the surrounding frame side plates include upper side plates 14 and lower side plates. 19. The left side plate 17 and the right side plate, the upper side plate, the lower side plate, the left side plate and the right side plate constitute a square frame structure. The left side panel is provided with a test port 18, and the left side plate is equipped with a standard sensor connected to the test port 18. In this embodiment, the standard sensor includes a standard pressure sensor and a standard flowmeter 19 arranged horizontally, and the standard flowmeter is arranged horizontally. The effect of gravity on the airflow can be avoided. The fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com