Sealed end face self-compensating radar water slide ring

A self-compensating, water-slip ring technology, which is applied to engine seals, instruments, radio wave measurement systems, etc., can solve the problems of conventional water-slip rings, such as complex structure and leakage, and achieve compact structure, high reliability, reliability and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

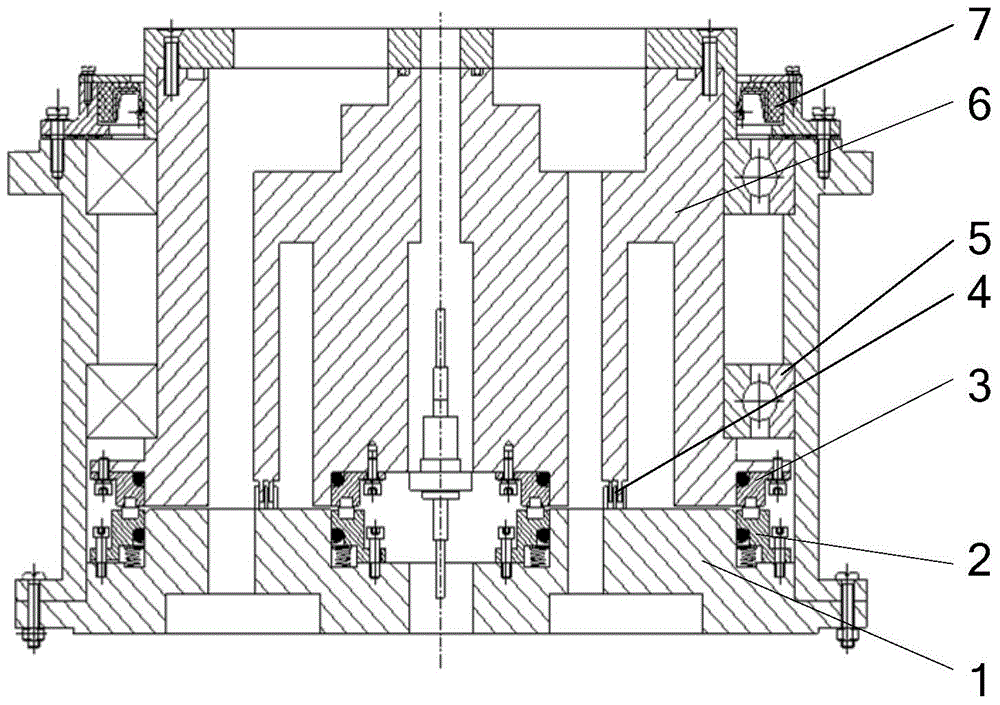

[0010] The present invention proposes a sealing end face self-compensating radar water slip ring, the structural features of which are as follows:

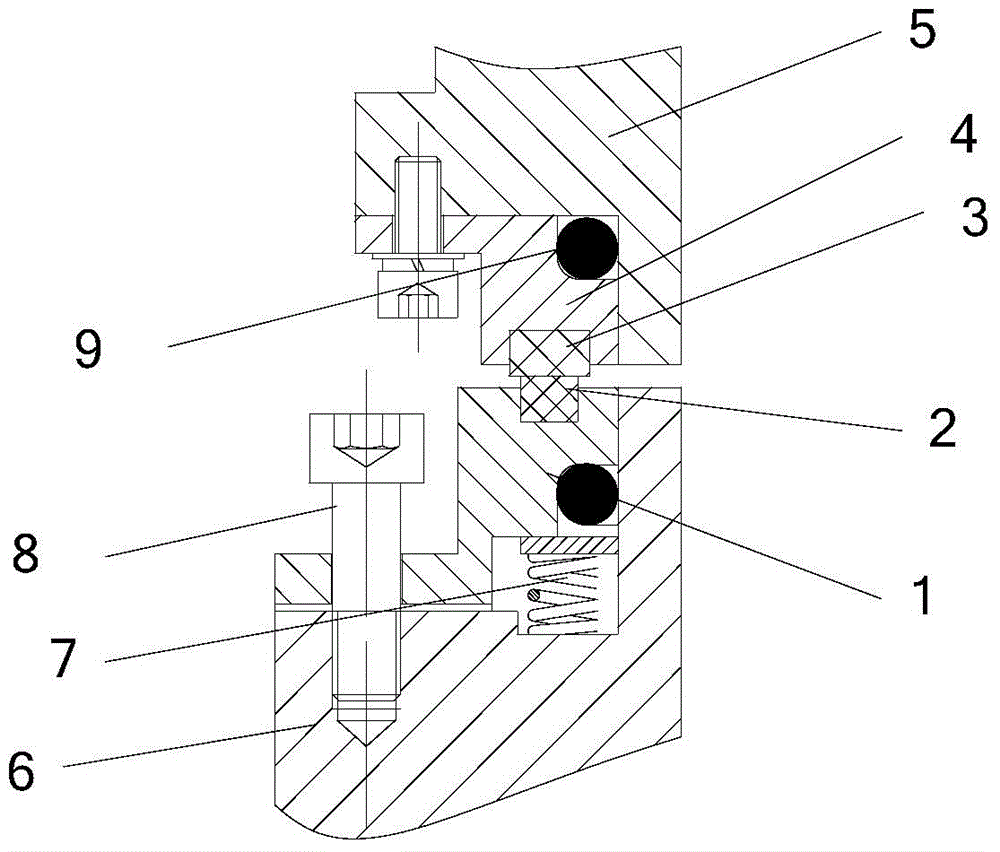

[0011] 1. Adopt self-designed mechanical seal

[0012] The sealing of the water slide ring in and out of the water channel and the outside world adopts a self-designed mechanical seal method, and its structure is as attached figure 2 shown. The mechanical seal includes a hard ring, a soft ring, a moving ring, a static ring, a spring, a guide screw and an O-ring. An O-ring is installed between the static ring and the static shaft, and between the moving ring and the rotating shaft. The moving ring passes through the tight The fixed screw is installed on the rotating shaft, the static ring is installed on the static shaft through the guide screw, and the spring is installed between the static ring and the static shaft. The soft ring is made of SiC+C material, and the hard ring is made of SiC material. Since these two materials ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com