Rebound type intelligent optical fiber distribution box suitable for remote control

An intelligent optical fiber and remote control technology, applied in the field of optical fiber wiring, can solve the problems of high cost, complex process, large equipment volume, etc., and achieve the effects of reducing manufacturing and use costs, convenient use, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the drawings and examples.

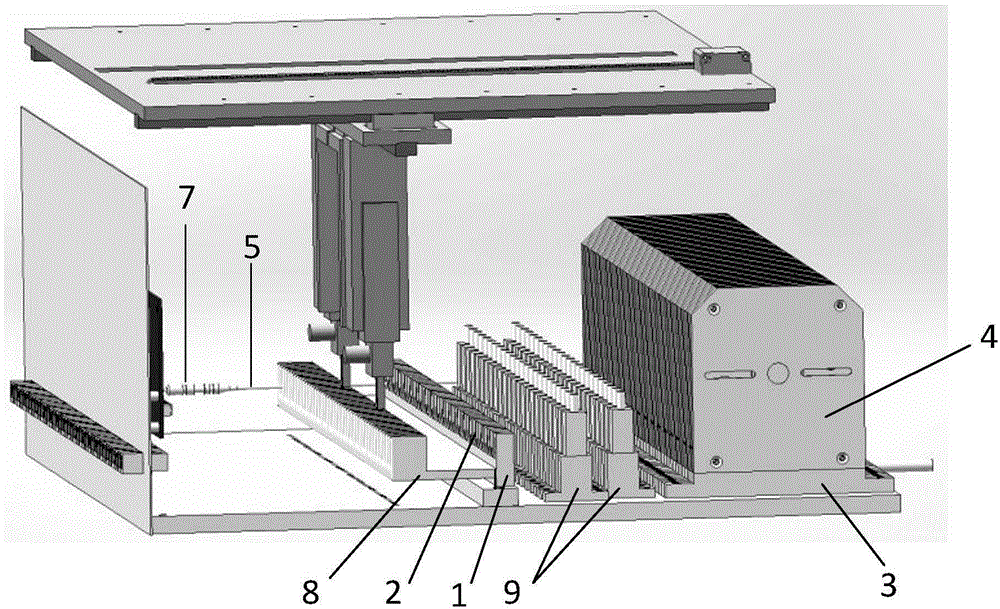

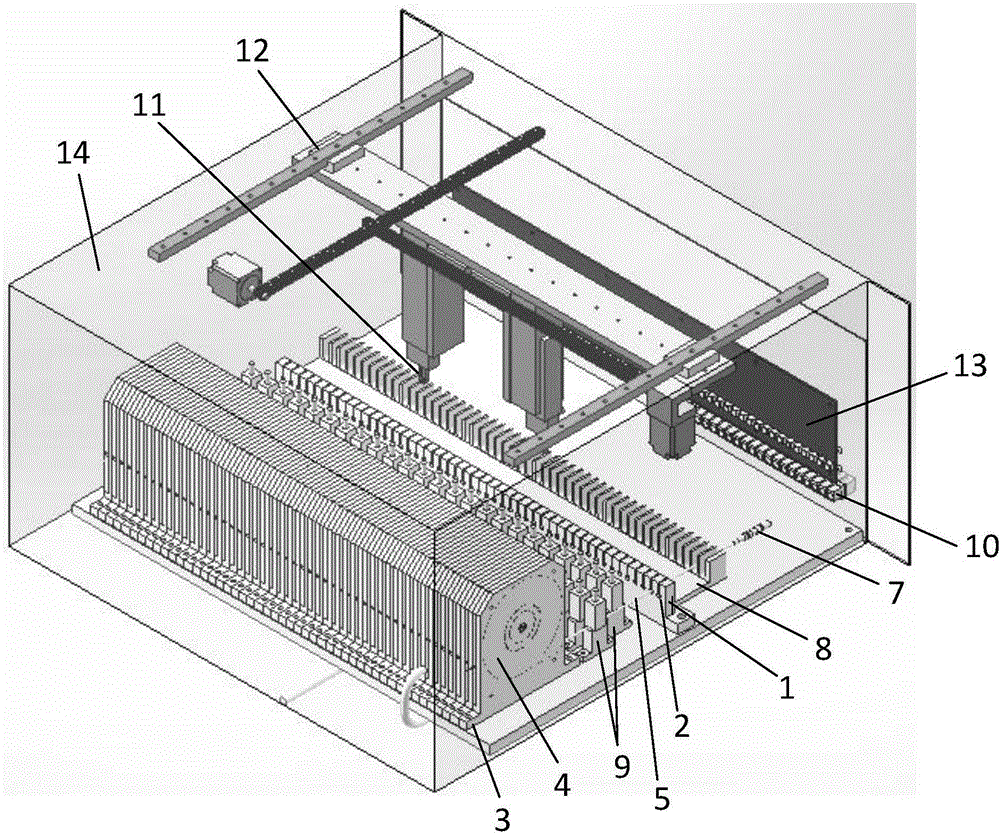

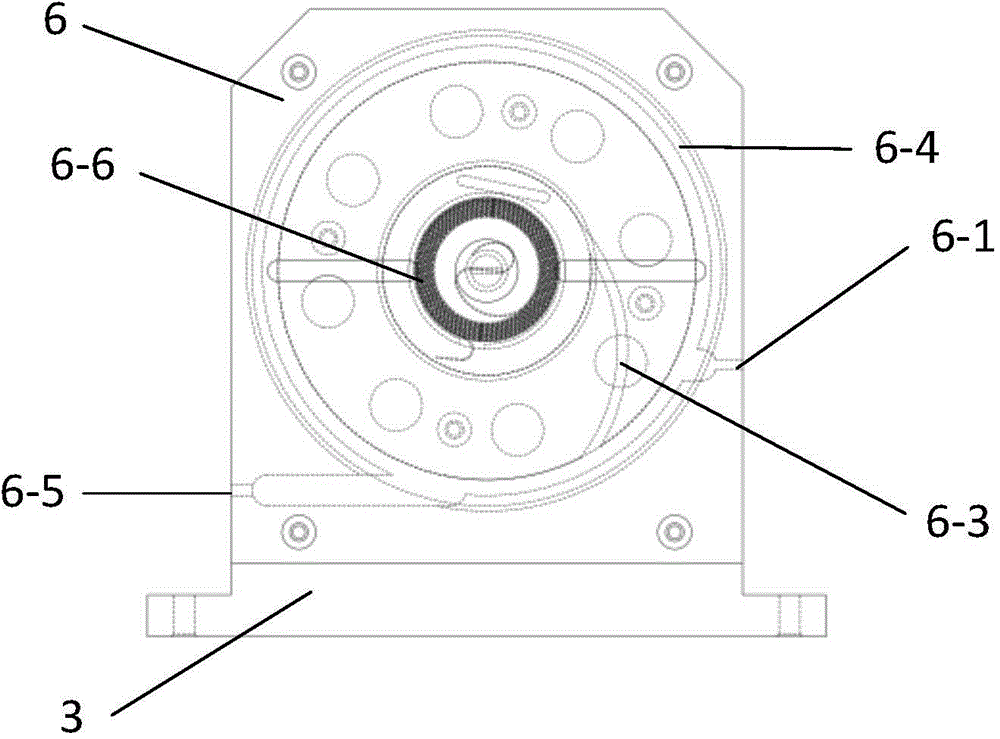

[0023] combine Figure 1A and Figure 1B , a resilient intelligent optical fiber distribution box suitable for remote control proposed by the present invention, including a box body and a user port optical fiber connection seat, an optical fiber positioning plate, and an optical fiber port positioning hole set on the optical fiber positioning plate. And the manipulator assembly: it also includes an optical fiber storage assembly and a mobile control unit; wherein: the optical fiber storage assembly includes an optical fiber tray base, an optical fiber tray group, and an optical fiber connector; the user port optical fiber connection seat, the optical fiber port positioning hole and The optical fiber disc group is arranged parallel to each other; the optical fiber disc group is composed of a plurality of optical fiber dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap