Bottle warmer for warming bottle sleeves

A technology of thermal insulation cover and milk warmer, which is applied to heating devices and other directions, and can solve the problems of hair dryer noise and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

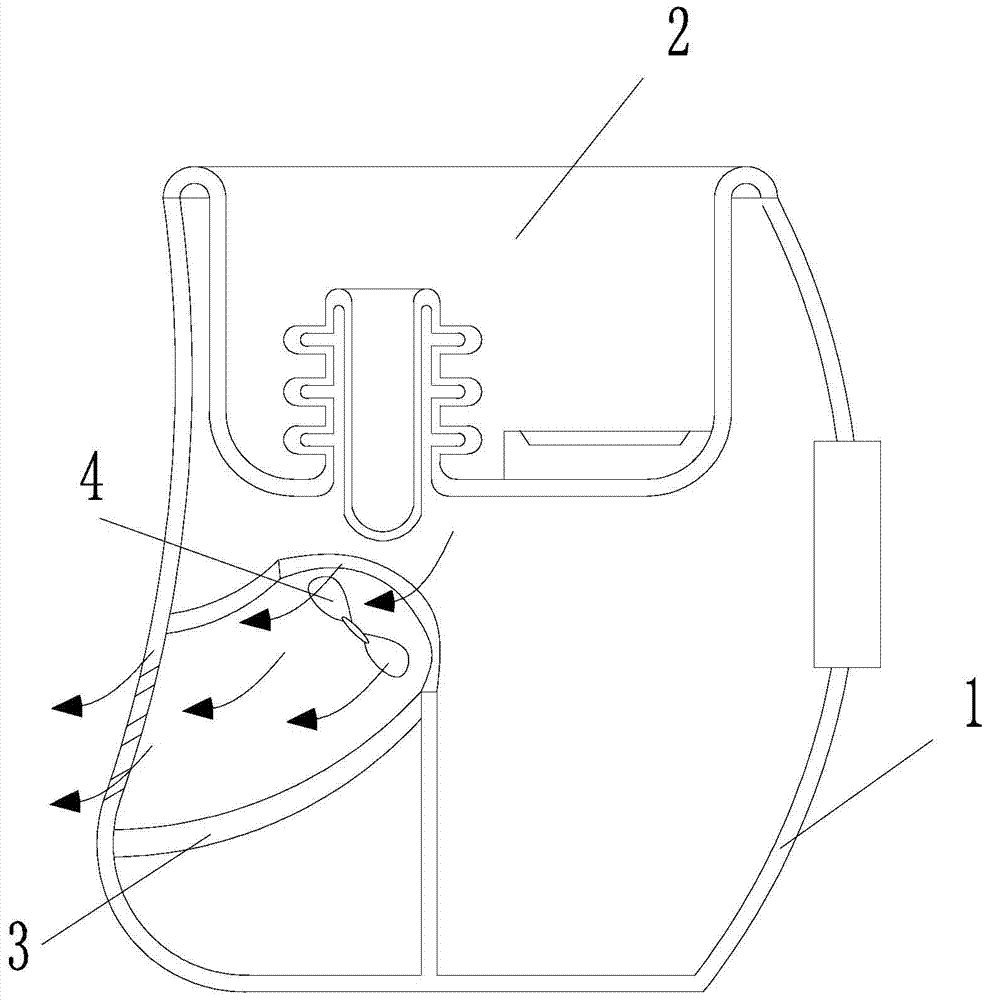

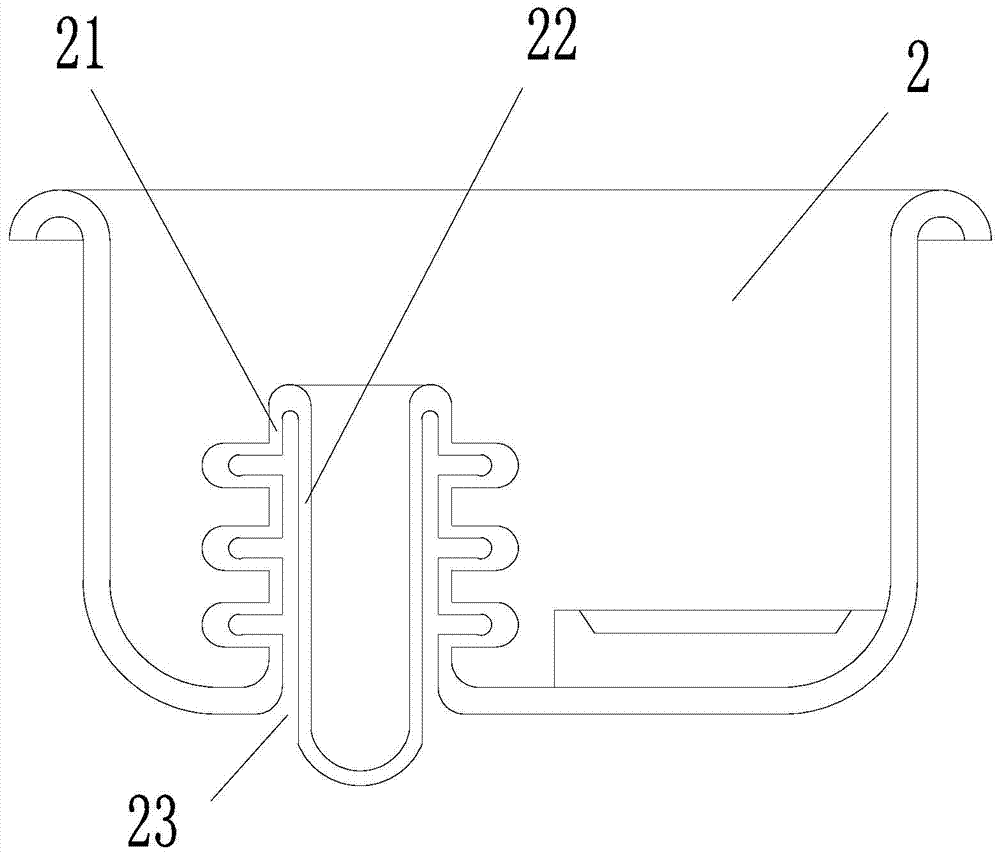

[0020] The present invention will be further described in conjunction with specific embodiment now. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0021] Such as figure 1 figure 2 As shown, a milk warmer capable of heating a baby bottle insulation cover includes a casing 1, an electric heating pot 2 is arranged on the upper end of the casing 1, the electric heating pot 2 includes a pot body, and the bottom wall of the pot body protrudes toward the inside of the pot body. Form the first cylindrical body 21 together, the bottom wall of the first cylindrical body 21 protrudes into the first cylindrical body 21 to form the second cylindrical body 22, and the inner wall of the first cylindrical body 21 and the outer wall of the second cylindrical body 22 form a Compartment 23 for accommodating a feeding bottle thermos.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com