A single-nozzle multi-source biological 3D printing device and method thereof

A 3D printing, bio-derived technology, applied in medical science, prosthesis, additive processing, etc., can solve the problems of printing nozzle interference control, complex printing mechanism, large volume, etc., to improve printing efficiency, easy assembly, device The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific structure, working principle and working process content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

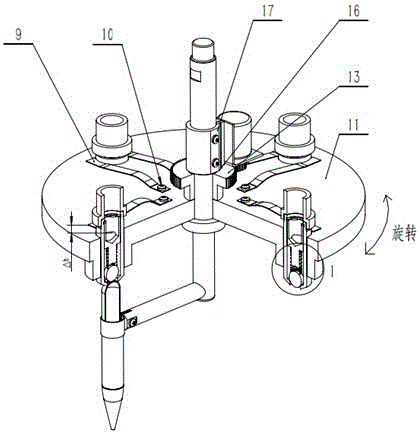

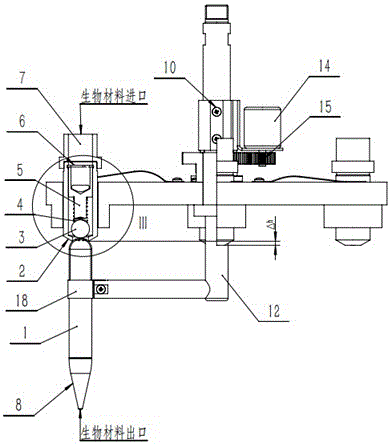

[0030] like figure 1 and image 3 As shown, a single-nozzle multi-material source biological 3D printing device includes a motor fixing seat 17, a motor 14, a driving gear 15, a fixed shaft 12, a turntable assembly, a nozzle body, a one-way connecting valve, a spring leaf 4 and a feed Tube connector 7: The turntable assembly (eg Figure 7 shown) is composed of a turntable 11 and a driven gear 13, and the two parts are assembled by welding: the nozzle body is composed of a spray tube 1 (such as Image 6 Shown) and nozzle 8 connection composition:

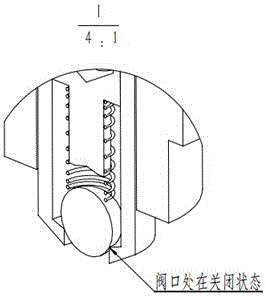

[0031] The one-way connection valve consists of one-way connection valve body 2 (such as Figure 5 As shown), steel ball 3, spring 4, spring seat 5, and circlip 6 for the hole are composed of: steel ball 3, spring 4, spring seat 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com