Method for dispersing carbon paste on pins PIN and carbon paste dispersing system

A carbon paste and foot point technology, applied in the field of liquid crystal display equipment, can solve problems such as low efficiency and poor electrode micro-short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

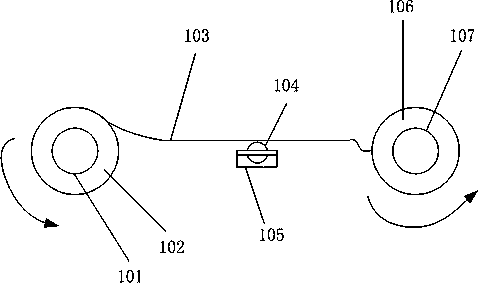

[0017] Present embodiment provides a kind of PIN foot point carbon slurry method, as figure 1 with figure 2 As shown, the PIN pin point carbon paste method comprises the following steps: first, step A: the first disc 107 and the second disc 101 that are wound with a strip-shaped PIN pin are placed on the transmission device, and the strip-shaped PIN roll is stretched 106 one end and fix it in the second disc 101, and make the bayonet of each PIN foot in the strip-shaped PIN roll 106 face down.

[0018] Wherein, when in use, the formed strip-shaped PIN roll can be used directly, and the strip-shaped PIN roll is formed by winding and fixing a number of strip-shaped PIN pins fixed with glue in the first disc, and the formed strip-shaped PIN roll can be directly use.

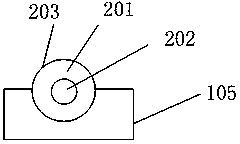

[0019] Then, perform step B: place the carbon slurry box 105 that carbon slurry is housed between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com