Automatic compression expansion type wastebin

A waste paper and automatic technology, which is applied in the field of trash cans, can solve the problems of occupying a large space and cannot automatically reduce the space occupied by waste paper, so as to achieve the effects of reducing the occupied space, avoiding the waste paper being wet, and increasing the capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

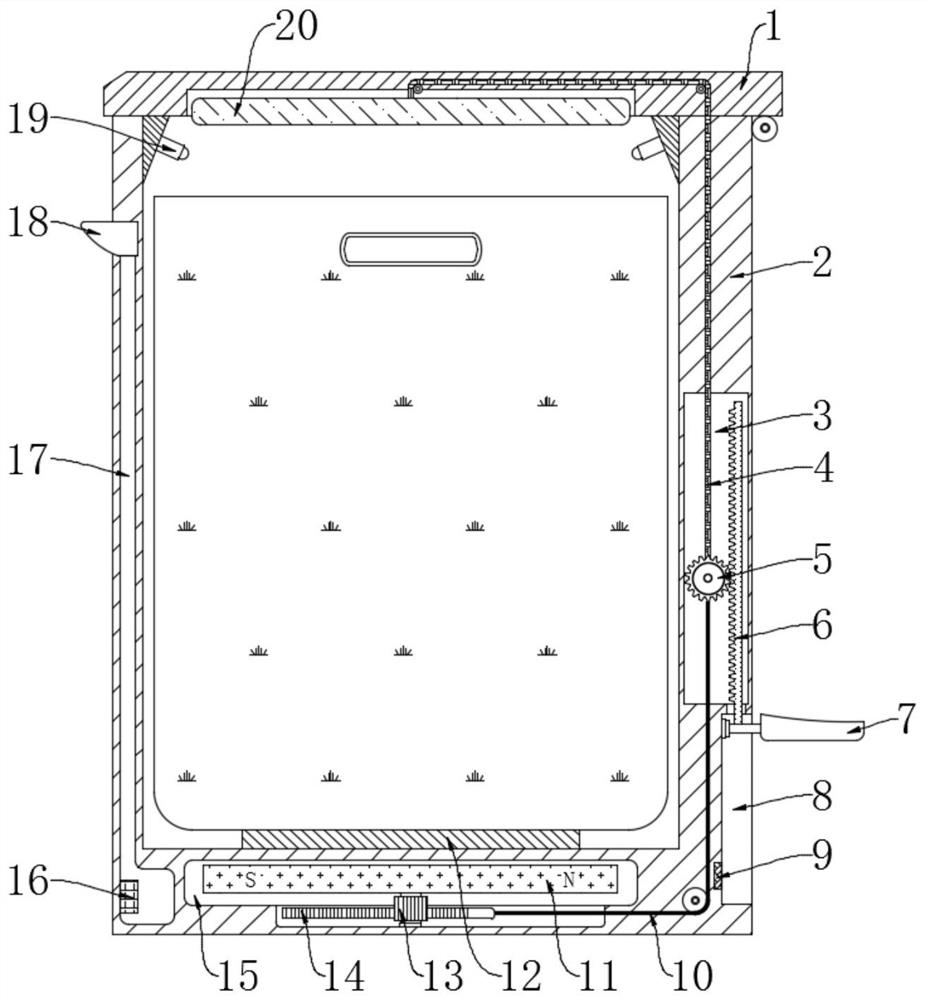

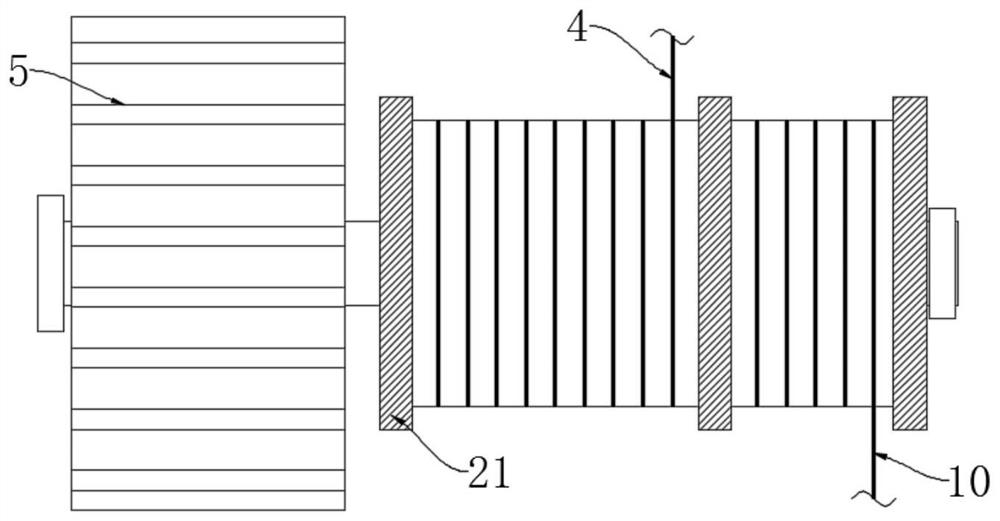

[0023] refer to Figure 1-2 , an automatic compression and expansion type waste paper bin, comprising a lid 1, an inner barrel body and an outer barrel body 2, vertical grooves 3 and liquid storage chambers 17 are symmetrically opened in the side wall of the outer barrel body 2, and the outer barrel body 2 is also provided with There is a liquid replenishment port 18 for replenishing liquid to the liquid storage chamber 17, a circular groove 15 is opened in the bottom wall of the outer barrel body 2, and a chute 8 is opened on the side wall of the outer barrel body 2, and the chute 8 is located in the vertical groove 3, a pedal 7 is slidably installed in the chute 8, and a trigger piece 9 is provided on the groove wall of the chute 8. When the pedal 7 is in contact with the trigger piece 9, the trigger piece 9 sends a specific electric signal, and the vertical groove 3 is installed with the first gear 5 and the first toothed plate 6 meshing with each other, and the lower end o...

Embodiment 2

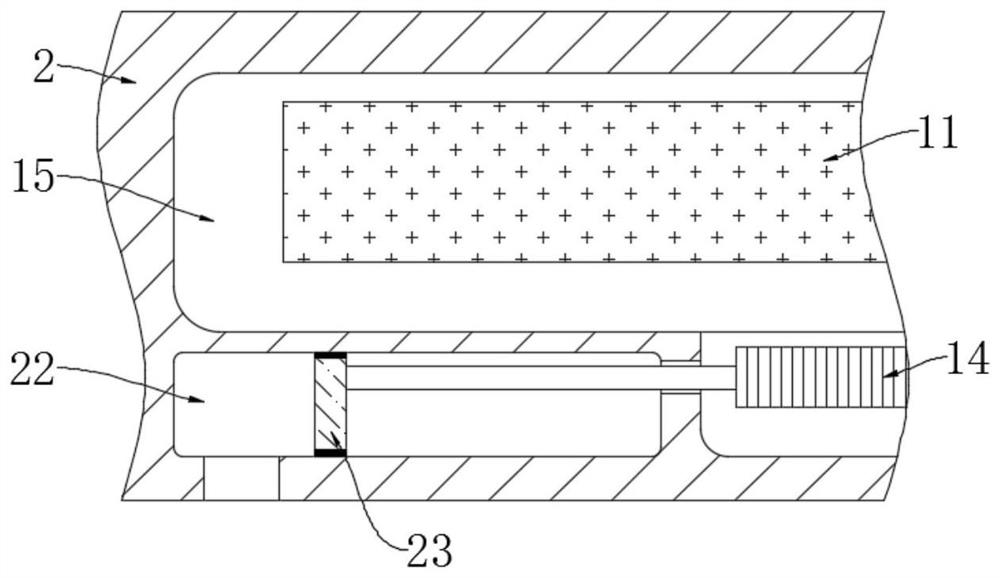

[0035] refer to image 3 The difference between this embodiment and Embodiment 1 is that a negative pressure chamber 22 is provided at the bottom wall of the outer barrel body 2, and a rubber plate 23 is provided for sealing and sliding in the negative pressure chamber 22, and the rubber plate 23 and the second tooth plate 14 A short rod is fixedly connected between them.

[0036]This embodiment can illustrate its functional principle through the following operation mode: when the pedal 7 is stepped on, when the bobbin 21 winds up the second pull cord 10, the second toothed plate 14 will drive the rubber plate 23 to slide to the right, so that the rubber plate Negative pressure is generated on the left side of 23, because the bottom surface of the outer barrel body 2 is flat and directly connected to the ground, so the outside air cannot be replenished in the negative pressure chamber 22, so a negative pressure space will be generated between the outer barrel body 2 and the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com