Transition metal nanoparticle catalyst coated with graphitized carbon layer and preparation method of transition metal nanoparticle catalyst

A nanoparticle and transition metal technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of poor catalytic activity and efficiency, low catalyst loading, poor cycle durability, etc. problems, to achieve the effect of abundant reserves, small particle size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

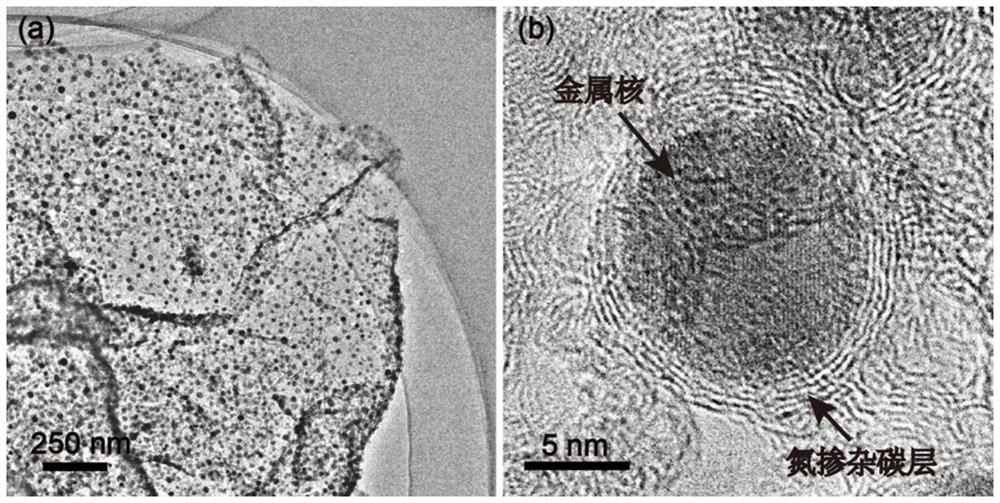

[0048] Firstly, a cobalt-iron hydroxide array supported on graphene is prepared, and 0.5 g of cobalt sulfate and 0.25 g of ferrous sulfate are dispersed in 100 ml of water and dissolved evenly. Then add 10 milliliters of 1 mg / ml uniformly dispersed graphene aqueous dispersion, stir at a constant speed for 30 minutes, then add 5 milliliters of ammonia water dropwise as a precipitating agent, continue to stir for 30 minutes and then centrifuge to obtain the hydroxide loaded on the graphene. Cobalt iron nanosheet arrays.

[0049] Then the above-mentioned cobalt-iron hydroxide array loaded on the graphene substrate is dispersed in 40 milliliters of water and 40 milliliters of ethanol mixed solution, stirred evenly until there is no obvious precipitation, and then 80 milligrams of trishydroxymethylaminomethane is used as the initiator of the polymerization reaction Dissolve in 40 ml of water and stir evenly, add the above mixed solution, and stir at a constant speed for 30 minutes....

Embodiment 2

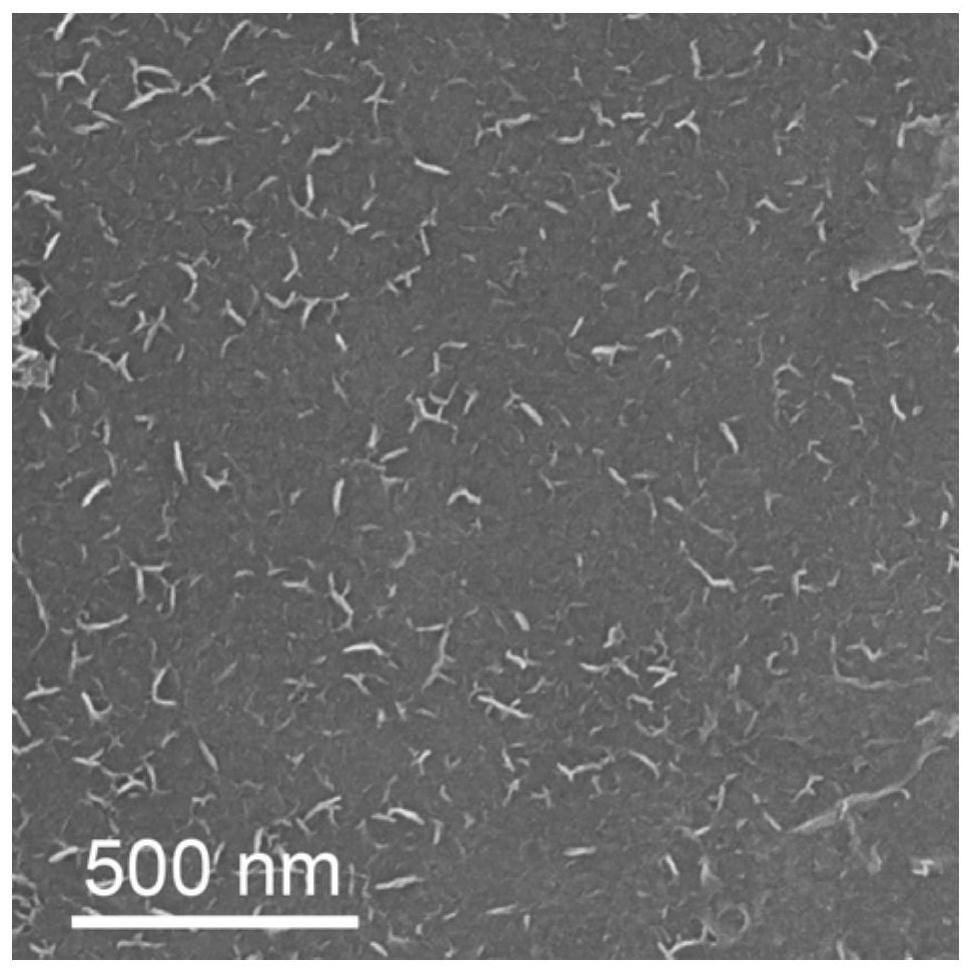

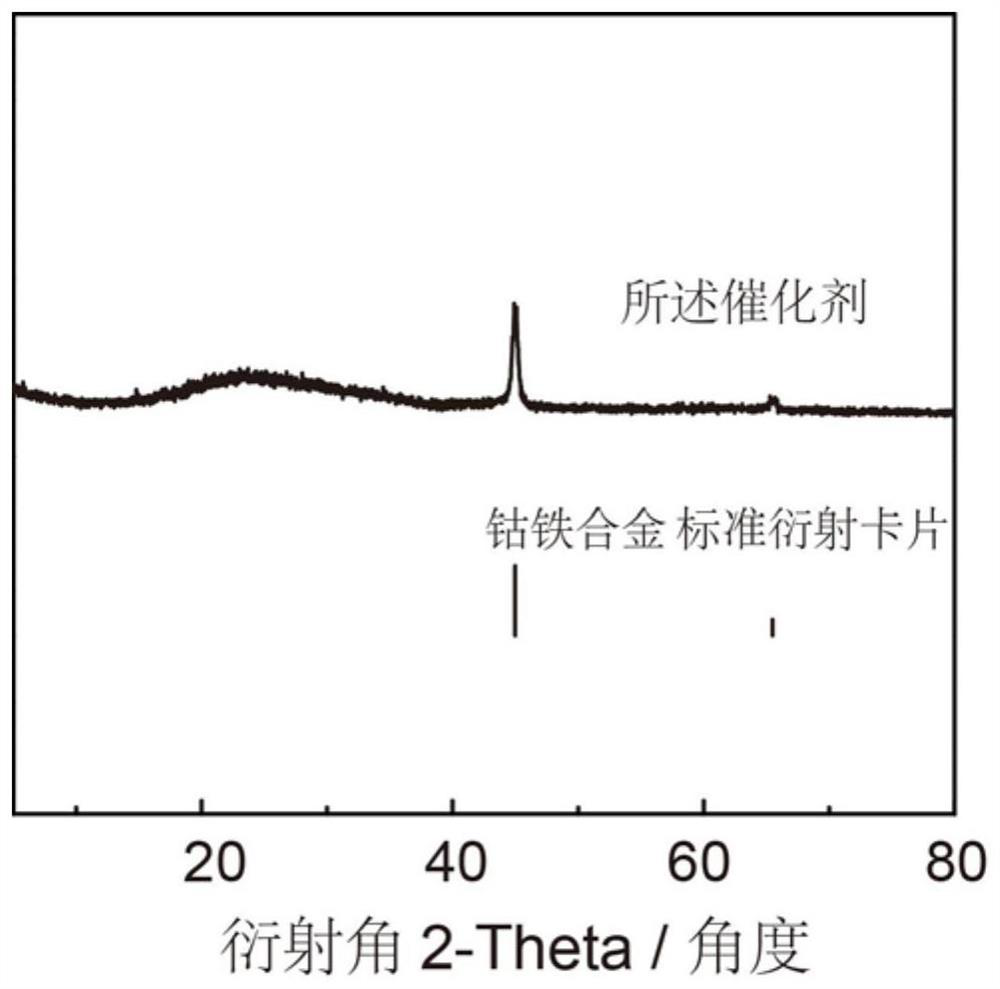

[0067] A catalyst in which nitrogen-doped graphitized carbon layer-coated transition metal nanoparticles was prepared in the same manner as in Example 1. The difference is that cobalt iron hydroxide is changed to cobalt hydroxide of equal mass (that is, only 0.75 g of cobalt sulfate is added in the process of preparing the hydroxide array), and the obtained catalyst is a high-loaded graphitized carbon layer coated cobalt nanometer. granular catalyst. The catalyst basically maintains a similar shape, wherein the content of metal cobalt is 41%, and the particle size of the catalyst is about 15nm.

Embodiment 3

[0069]A catalyst in which nitrogen-doped graphitized carbon layer-coated transition metal nanoparticles was prepared in the same manner as in Example 1. The difference is that cobalt iron hydroxide is changed to nickel iron hydroxide of equal quality (that is, the feed metal is changed to 0.5g nickel salt and 0.25g iron salt in the process of preparing the hydroxide array), and the resulting catalyst is a high loading Graphitized carbon layer-coated nickel-iron alloy nanoparticle catalysts. The catalyst basically maintains a similar shape, wherein the content of metal nickel and iron is 47%, and the particle size of the catalyst is about 15nm.

[0070] Example 3

[0071] A catalyst with graphitized carbon layer-coated transition metal nanoparticles was prepared in the same manner as in Example 1. The difference is that the polymer is replaced by an equal mass of polymerized phenolic resin, and the obtained catalyst is a graphitized carbon layer-coated cobalt-iron alloy nanop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com