Wearing part with a wear indicator and system for wear testing

A technology for indicating parts and wear status, applied in vehicle parts, tire parts, testing wear resistance, etc., can solve the problems of high cost, high quality, expensive sensors, etc., and achieve the effect of small failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] figure 1 A perspective view of a vehicle tire 1 is shown, in which a wear indicator in the form of a multi-layered QR® code 3 is introduced into the running surface 2 . The QR® code is implemented as an iQR code, which is especially suitable for cylindrical surfaces.

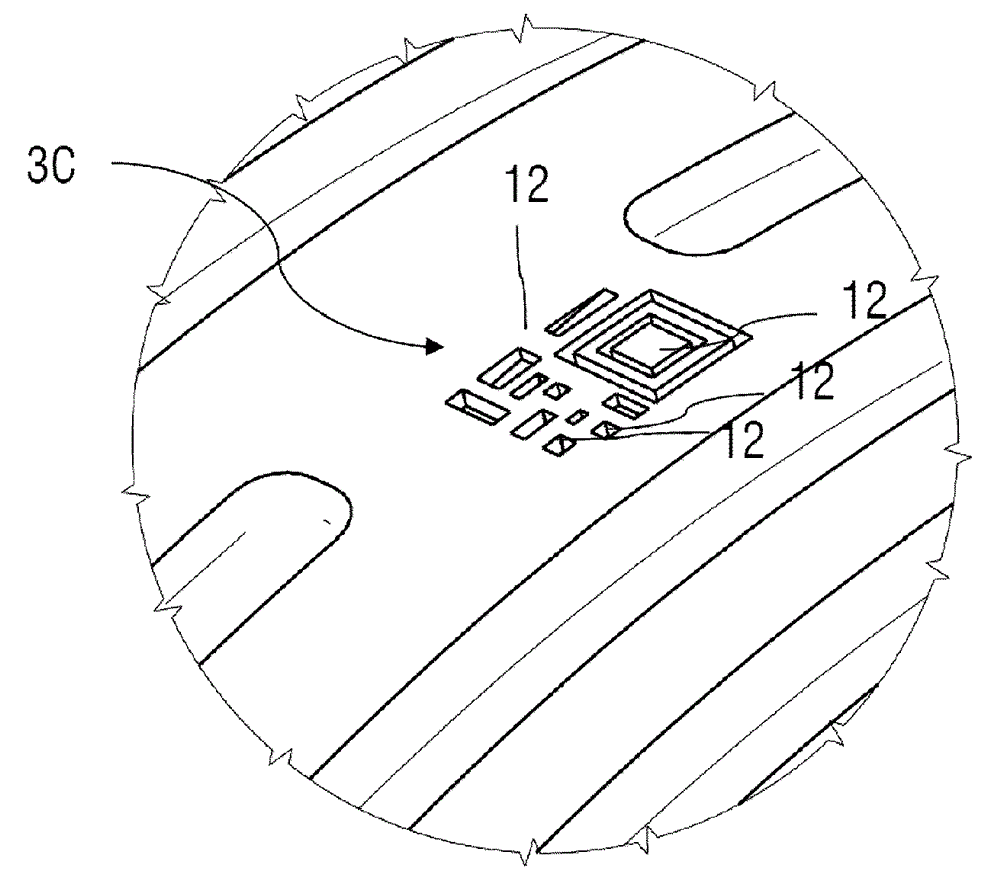

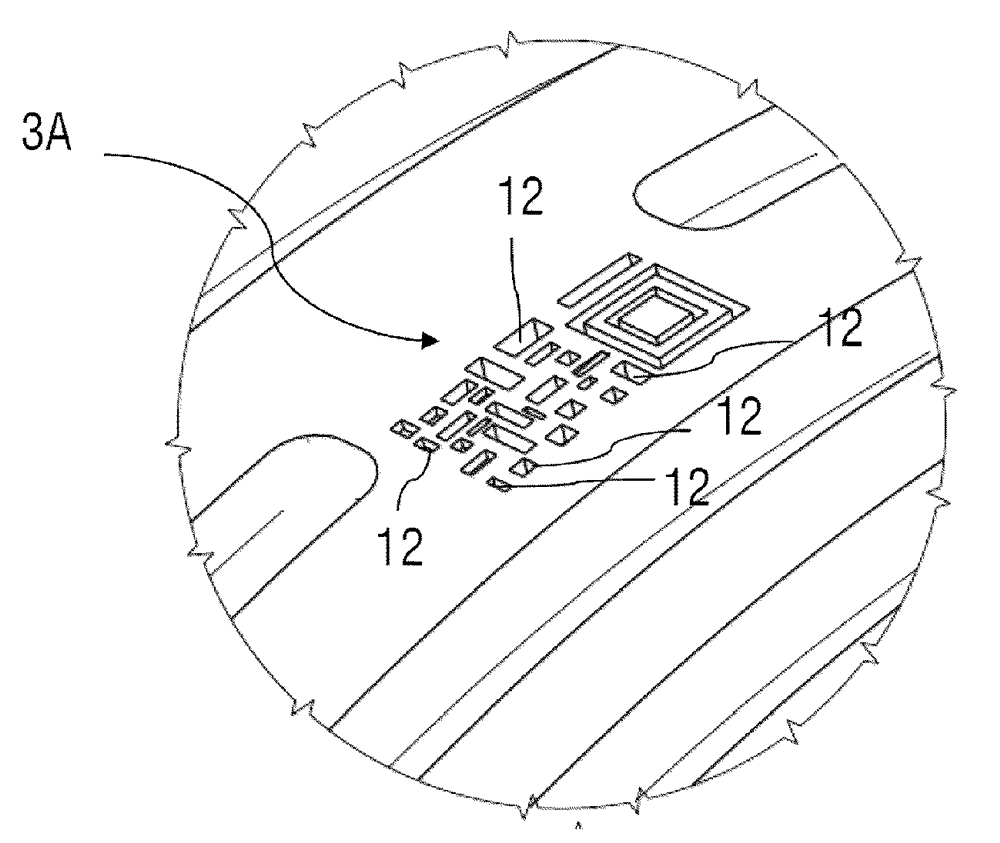

[0067] Figure 2A shown figure 1 An enlarged perspective view of part A of , and Figure 2B shown figure 1 An enlarged top view of part A of . Figure 2A and 2B In particular the uppermost plane 3A of the QR® code in the new state of the tire is shown.

[0068] The information carrier of the QR code, ie the black dots and stripes 12 of the QR code, are formed by the tire material. For reasons of simplified visibility and better visibility, only some of the dots or stripes of the QR® code are indicated with reference numeral 12 .

[0069] The gaps between the information carriers 12 are each embodied as recesses. The current form of the QR® code digitally describes the state of tire wear and other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com