Slurry transfer cart

A technology for transporting vehicles and slurry, applied in the direction of vehicles, motor vehicles, transport objects, etc. used for freight transportation, can solve the problems of poor unloading effect, weak vibration, affecting the use effect, etc., and achieves clean structure, strong vibration, The effect of reducing space occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

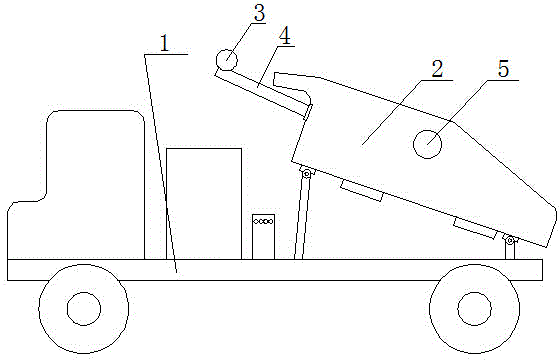

[0010] Such as figure 1 As shown, a slurry transport vehicle includes a vehicle frame 1 and a vehicle bucket 2, and a vibrating device 3 is also provided on the vehicle bucket. The rear part of the vehicle bucket is hinged on the vehicle frame, and its feature is: there is The hinged extension arm 4, the vibration device is installed on the extension arm.

[0011] Due to the arrangement of the extended arm, the effect of vibration is more obvious, and the effect of greater power of raw materials can be achieved with a smaller filtering vibration device, which has the advantages of the present invention.

[0012] Furthermore, there is a groove 5 on the middle side of the bucket, and the vibrating device is located in the groove when the extension arm is folded back, which saves space when the extension arm is folded.

[0013] The above descriptions are only specific e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com