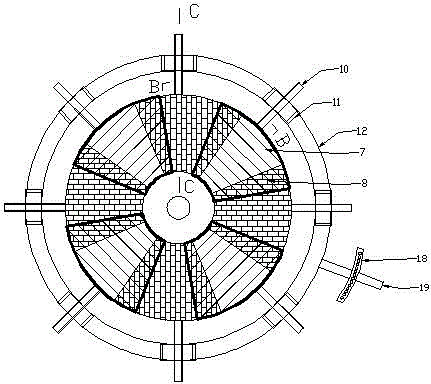

Carbon black reaction furnace

A reaction furnace and carbon black technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, chemical industry, etc., can solve problems such as failure to achieve expected goals, fluctuation of carbon black product quality indicators, etc., to save energy and improve Controllability and yield improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Example 1: Comparative analysis of the process of producing N234 carbon black in conventional reaction furnace and reaction furnace of the present invention. From the data in Table 1, it can be seen that in the case of different fuels in the reaction furnace, the amount of fuel is different, which will cause the length of the flame to be different. The lower limit of the range, through the adjustment of the diameter of the air inlet and the position of the spray gun of the present invention, the oil absorption value of the structure degree has increased by 2.9-5.28%, the coloring intensity of the aggregate distribution has increased by 2.9-5.28%, and the yield has also increased by 2.9-5.28% %.

[0033] Table 1

[0034]

example 2

[0035] Example 2: Table 2 compares and analyzes the process of producing N330 carbon black with the conventional reaction furnace and the reaction furnace of the present invention. By adopting the adjustment of the air inlet diameter and the position of the spray gun of the present invention, the structural oil absorption value is increased by 2.85-3.3%, the aggregate distribution coloring intensity is increased by 5.05-5.15%, and the yield is also increased by 0.68-1.2%.

[0036] Table 2

[0037]

[0038]

example 3

[0039] Example 3: Comparative analysis of the process of producing N351 carbon black by conventional reaction furnace and reaction furnace of the present invention. As can be seen from the data in Table 3, when the reaction furnace produces different types of carbon black, the air intake volume is different, which will cause the flame length to be different. The value is at the lower limit of the standard range. After adjusting the diameter of the air inlet and the position of the spray gun of the present invention, the oil absorption value of the structure degree is increased by 4.85-6.43%, the coloring intensity of the aggregate distribution is increased by 7.22-7.29%, and the yield is also increased by 1.83-2.29% %.

[0040] table 3

[0041]

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com