Material and preparation method of bioimaging probe and oxygen reduction catalyst

A bioimaging and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, luminescent materials, etc., can solve problems such as the gap in catalytic ability, and achieve low production costs, easy mass production, and broad industrial application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 30 mL of N-methylpyrrolidone in a 50 mL round bottom flask and heat to 200°C for 3 hours. After the reaction was completed, the product was cooled, and the product was dialyzed in water for 3 days to remove the solvent. Finally, the product was frozen in liquid nitrogen, and then freeze-dried using a freeze dryer for 3 days to obtain quantum dot powder.

[0021] Take 0.5 g of quantum dot powder and place it in a tube furnace, heat it to 800° C. under the protection of argon for 2 hours, and cool it under the protection of argon to obtain a black lump.

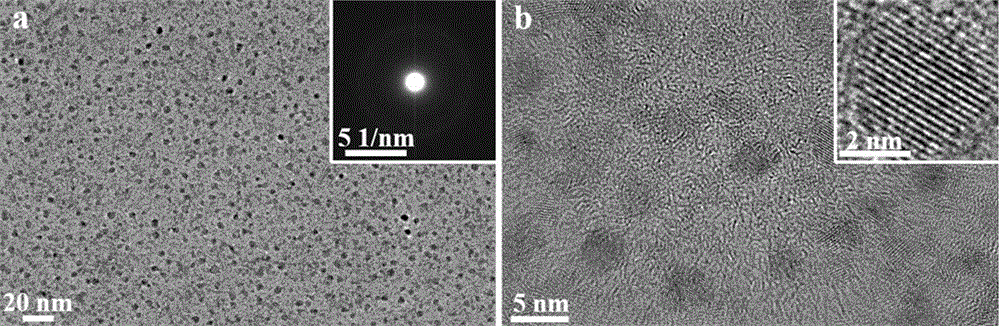

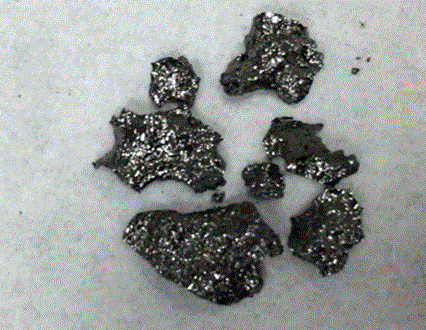

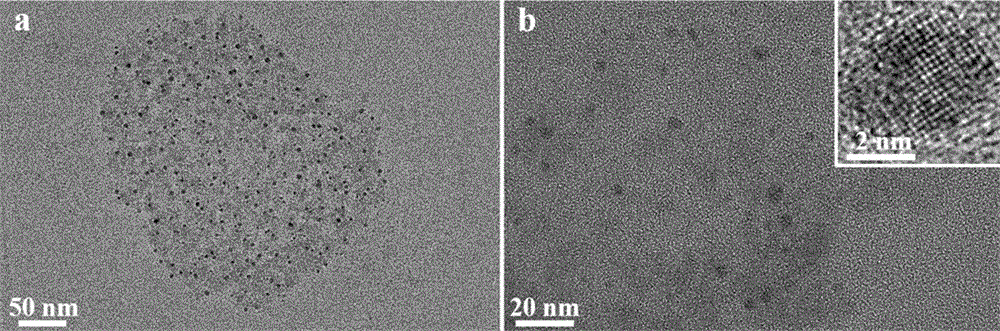

[0022] From figure 1 It can be seen that the prepared carbon quantum dots have a very uniform size and very obvious lattice fringes, indicating that they have good crystallinity. From figure 2 It can be found that after the quantum dots are heated at high temperature, the product is macroscopically a blocky solid with metallic luster. From image 3 It can be seen from the figure that after the quantum dots are...

Embodiment 2

[0024] Take 50 mL of N-methylpyrrolidone in a 100 mL round bottom flask and heat to 90°C for 72 hours. After the reaction was completed, the product was cooled, and the product was dialyzed in water for 2 days to remove the solvent. Finally, the product was frozen in liquid nitrogen, and then freeze-dried for 4 days using a freeze dryer to obtain quantum dot powder.

[0025] Take 1 g of quantum dot powder and place it in a tube furnace, heat it to 1100° C. under the protection of argon for 1 hour, and cool it under the protection of argon to obtain a black lump.

Embodiment 3

[0027] Take 30 mL of N-methylpyrrolidone in a 100 mL round bottom flask and heat to 140°C for 6 hours. After the reaction was completed, the product was cooled, and the product was dialyzed in water for 2 days to remove the solvent. Finally, the product was frozen in liquid nitrogen, and then freeze-dried for 5 days using a freeze dryer to obtain quantum dot powder.

[0028] Take 1.5 g of quantum dot powder and place it in a tube furnace, heat it to 500° C. under the protection of argon for 6 hours, and cool it under the protection of argon to obtain a black blocky substance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com