Anti-freeze retaining wall for water conservancy project

A technology for water conservancy projects and retaining walls, applied in water conservancy projects, water conservancy engineering equipment, infrastructure engineering and other directions, can solve the problems of poor frost resistance, easy damage, limitations of applicability and practicability, etc., to improve the frost resistance performance. , Good use stability, improve the effect of anti-overturning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

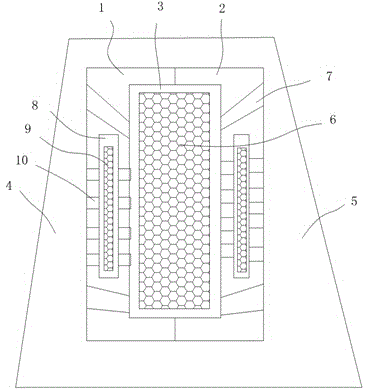

[0012] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0013] See figure 1 , a water conservancy engineering antifreeze retaining wall, comprising a retaining wall body, the retaining wall body includes a left retaining piece 1 and a right retaining piece 2, and an anti-freeze is arranged between the left retaining piece 1 and the right retaining piece 2 In the freezing gap 3, an inclined left wrapping layer 4 is arranged on the outside of the left flap 1, an inclined right wrapping layer 5 is arranged on the outside of the right flap 2, and an antifreezing The particle filling layer 6 is provided with vegetation holes 7 on the left blocking piece 1 and the right blocking piece 2 .

[0014] A cavity 8 is provided in the left baffle 1 and the right baffle 2, and a temperature expansion material particle filling layer 9 is arranged in the cavity 8. In the left baffle 1 and the right ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com