Stereo garage lifting device and stereo garage

A technology of three-dimensional garages and lifting parts, which is applied in the direction of buildings, building types, and buildings where cars are parked, and can solve problems such as unstable pressure bars, hidden safety hazards, and complicated installation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

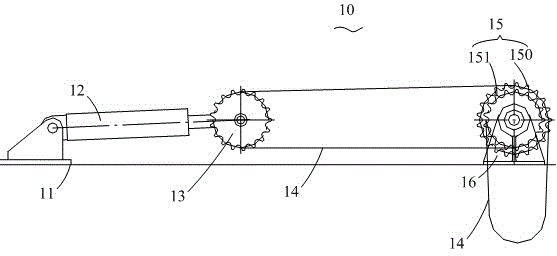

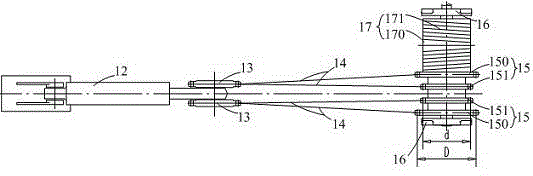

[0014] Please see as figure 1 and figure 2 , the lifting device 10 for the three-dimensional garage includes a support base 11, a power source cylinder 12, a balance sprocket 13, an endless chain 14, a differential sprocket 15, a bearing support 16, a lifting member 17, a power source cylinder 12, a balance sprocket 13. The endless chain 14, the differential sprocket 15, the bearing support 16, and the lifting member 17 are fixed on the support base 11. The power source cylinder 12 is located at one end of the support base 11. The telescopic end of the power source cylinder 12 and the balance sprocket 13 Fixedly connected, and the telescopic end of balance sprocket 13 and power source oil cylinder 12 can rotate relatively, and bearing support 16 is positioned at the other end of support base 11, and bearing support 16 is opposite to the telescoping end of power source oil cylinder 12, and lifter 17 and The differential sprocket 15 is coaxially fixed and installed on the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com