High efficient wax-prevention viscosity reduction and oil increasing apparatus

A wax-prevention and viscosity-reducing technology, applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of heavy pumping unit workload, difficult oil production operations, and high wax content in crude oil, and increase the flow of crude oil. capacity, reducing the number of well flushes, and increasing the effect of oil well production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

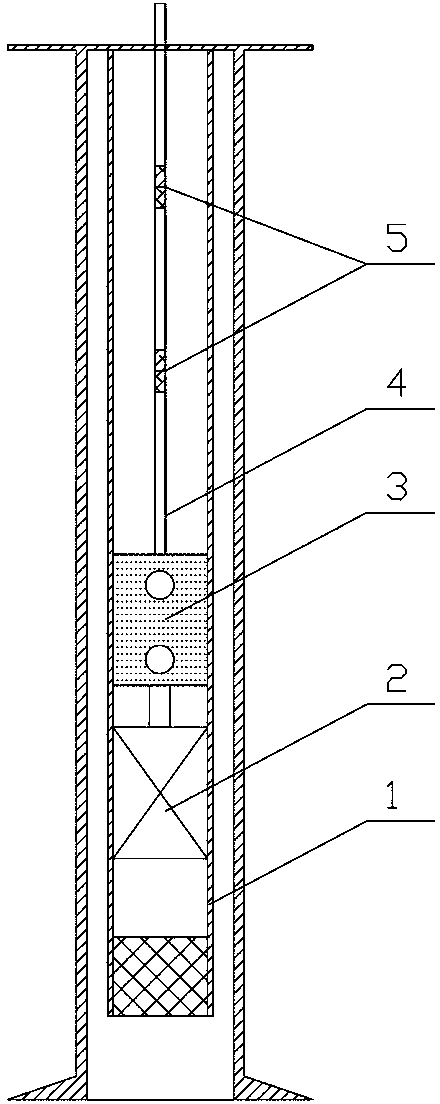

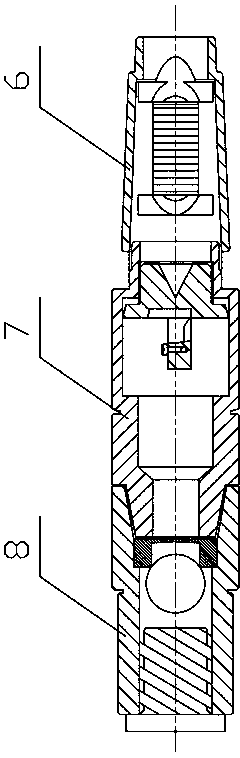

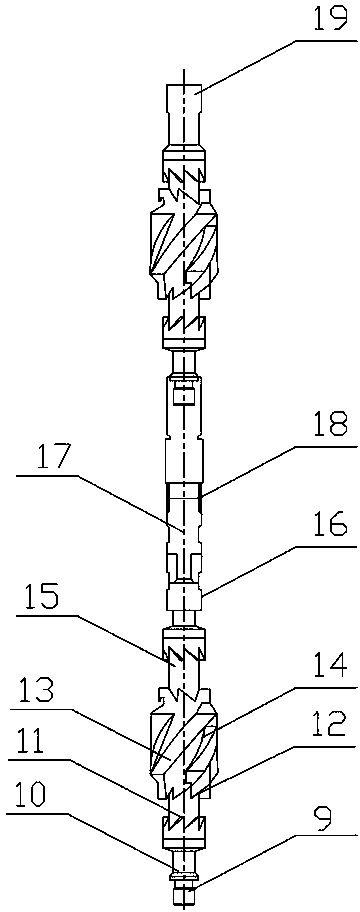

[0017] see figure 1 , the present invention includes a sucker pipe 1 and a sucker rod 4, a sucker pump 3 is installed at the lower end of the sucker rod 4, and a primary anti-wax viscosity-reducing oil booster 2 is installed at the lower end of the sucker rod, especially: 4 The lower section is close to the oil well pump 3, and at least one set of rod-type swirl magnets 5 is plugged in. The rod-type swirl magnets (see image 3 ) has a connecting rod 17, and a swirl centralizer is installed at the upper and lower ends of the connecting rod; the swirl centralizer includes a mandrel 15, a centralizer 13 is installed in the middle of the mandrel, and 2-4 heads are arranged on the outer wall of the centralizer Spiral groove 14, the two ends of the centralizer are in a straight zigzag shape 12, and the serrations 12 on both end surfaces are oppositely inclined, and left and right stop sleeves 10 and 16 are designed at both ends of the mandrel, and the stop sleeves face the end faces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com