Intelligent burst coal mining method

A coal mining method and intelligent technology, applied in ground mining, earth square drilling, underground mining, etc., can solve problems such as incomplete coal wall cleaning, high labor intensity of personnel, and difficulty in coal block cleaning, so as to reduce manual labor intensity, The effect of low labor intensity, coal mining efficiency and high lump coal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

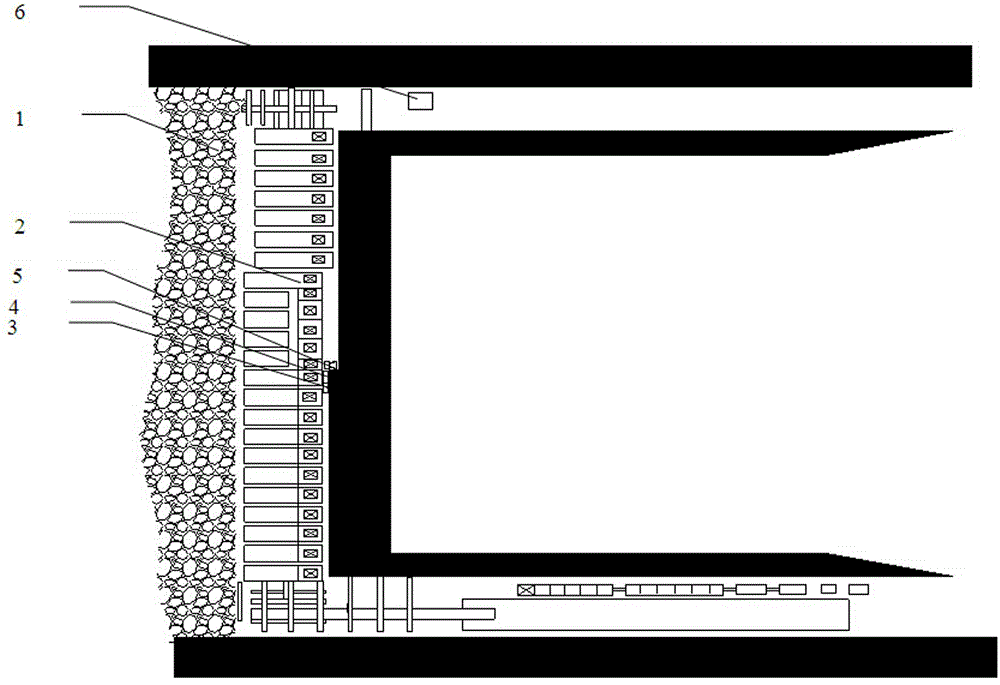

[0021] Below is the combined figure 1 The present invention will be further described with implementation examples.

[0022] The technical scheme of the present embodiment is carried out according to the following steps:

[0023] (1) Drilling work is carried out before blasting, and the intelligent drilling vehicle 3 drives to the designated working face position, and is controlled by the intelligent drilling vehicle 3 according to the pre-designed hole position, hole distance, hole depth, blasthole angle and blasthole length 4~ 6 mechanical arms realize accurate positioning of the hole forming position and quickly and automatically fine-tune the hole forming position. After positioning, the hydraulic drilling rig is used to drill to realize the automatic and rapid hole forming of the drill bit;

[0024] (2) The 4 robotic arms of the intelligent charging device are used to automatically position and charge the explosives with a diameter of Ф60, and the new KYFK-001 sealing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com