Water level controller for air flotation machine

An air flotation machine and controller technology, which is applied in flotation water/sewage treatment, mechanical equipment, engine components, etc., can solve problems such as failure to achieve results and inability to remove floating sludge, and achieve convenient operation, accurate water level control, The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with accompanying drawing and example:

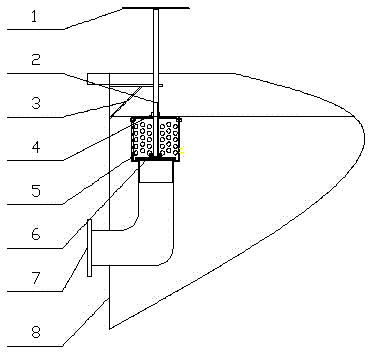

[0011] A water level controller for an air flotation machine, comprising a handle 1, a screw rod 2, a bracket 3, a nut 4, a valve body 5, a valve core 6, a drain port 7, an air flotation machine box 8, and the bracket 3 is welded on the inside of the air flotation machine box 8 The upper part of the bracket 3 is provided with a threaded hole matched with the screw rod 2, the upper end of the screw rod 2 is welded with a handle 1, the lower end of the screw rod 2 is provided with a valve body 5, and the valve body 5 is provided with a valve core 6, the valve core 6 and The lower ends of the screw rods 2 are connected, the lower part of the valve body 5 is connected with the drain port 7 through a pipeline, and the upper part of the valve body 5 is provided with a nut 4 matched with the screw rod 2 .

[0012] Further, water inlet holes are evenly opened on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com