Siphon type liquid level control valve and control method thereof

A liquid level control, siphon type technology, applied in the field of liquid level control valves, can solve the problems of the main valve or float valve opening and closing, unstable opening and closing, pressure fluctuating high and low, internal valve difficult to close, etc. To achieve the effects of not being prone to a large amount of water overflow, preventing leakage and reducing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings:

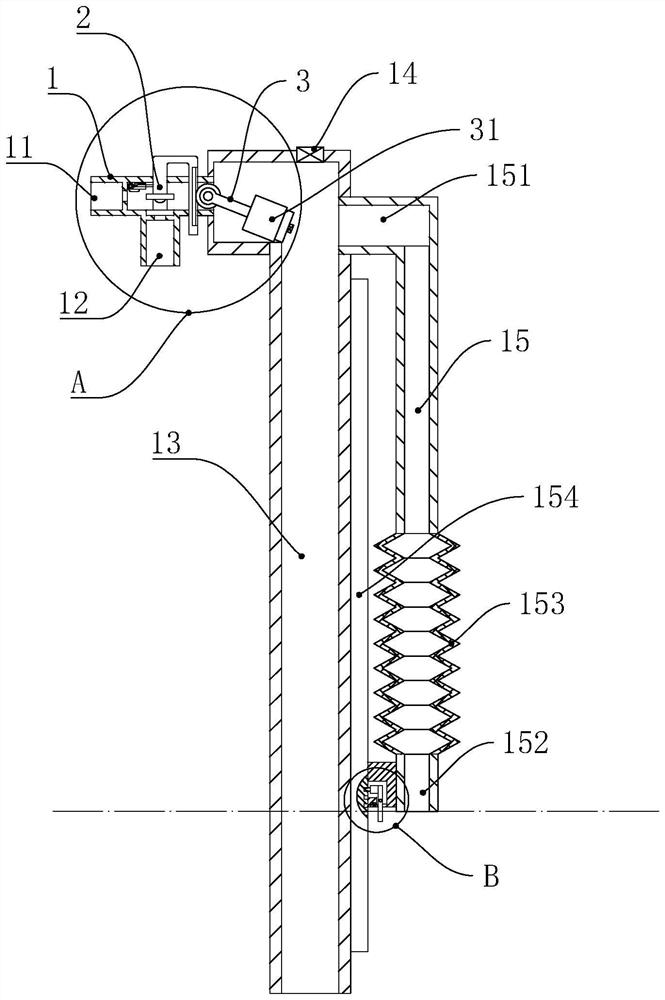

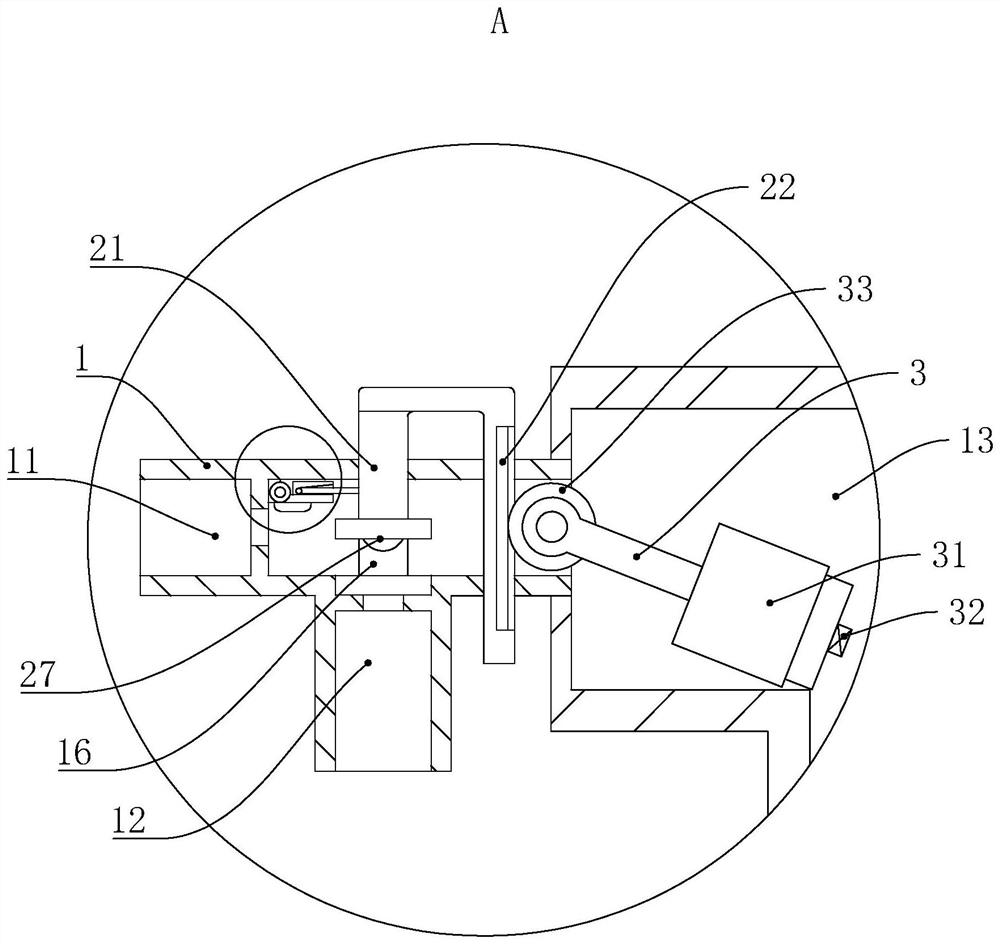

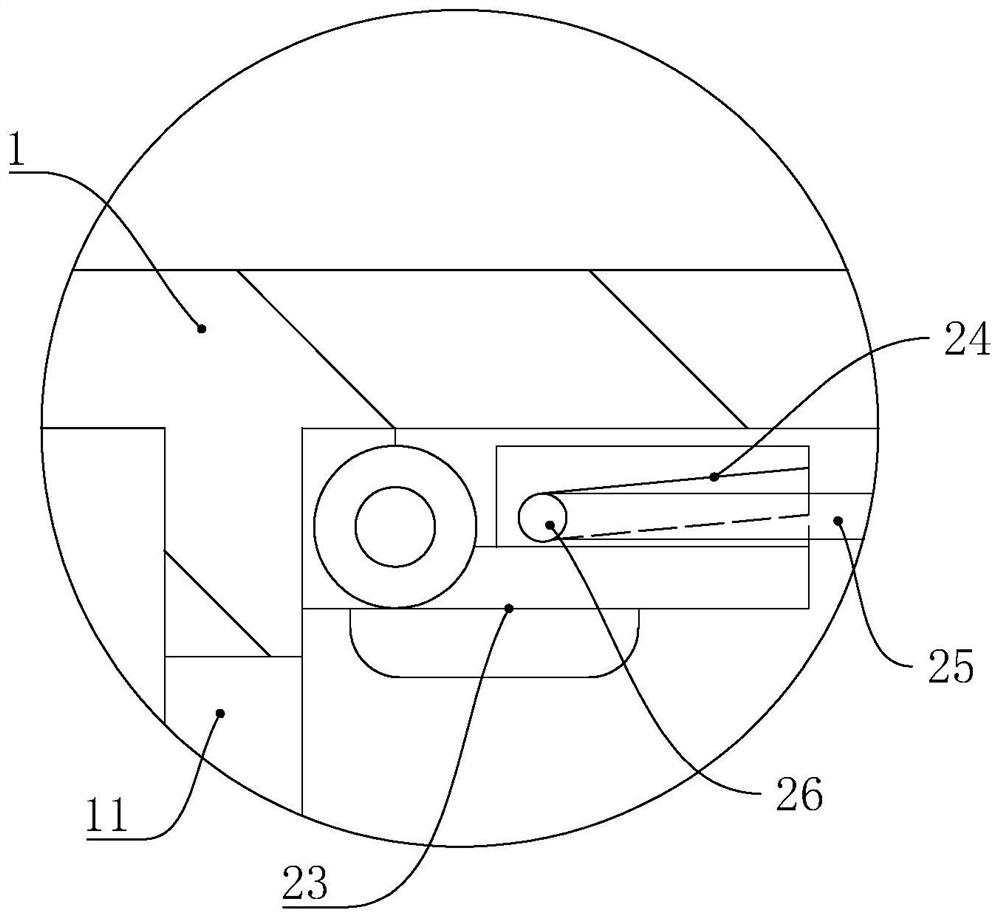

[0020] Referring to the drawings: the siphon type liquid level control valve in this embodiment includes a floating ball valve. The floating ball valve includes a valve body 1, a valve core 2, a crank arm 3 and a floating ball 31. The two ends of the crank arm 3 are respectively Connected with the valve core 2 and the floating ball 31, the valve body 1 is provided with a water inlet 11 and a water outlet 12 that communicate with each other. When the crank arm 3 rotates, the valve core 2 is driven to move, so that the valve The core 2 gradually closes the water inlet 11, which is characterized in that: the valve body 1 is fixedly connected with a cylinder body 13 with an open lower end, the crank arm 3 and the floating ball 31 are located in the cylinder body 13, and the upper end of the cylinder body 13 is located in the cylinder body 13. Closed and provided with a one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com