Truss type erecting arm

A vertical arm and truss-type technology, applied in the field of vehicle-mounted thermal launch of weapons, can solve the problems of bulky structure, waste of space, unfavorable layout, etc., and achieve the effect of high bending section, reduced space size, and simple and reliable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. Please refer to the accompanying drawings and describe the present invention in detail below in conjunction with the embodiments. The accompanying drawings are only for reference and description, and do not constitute a limitation to the patent protection scope of the present invention.

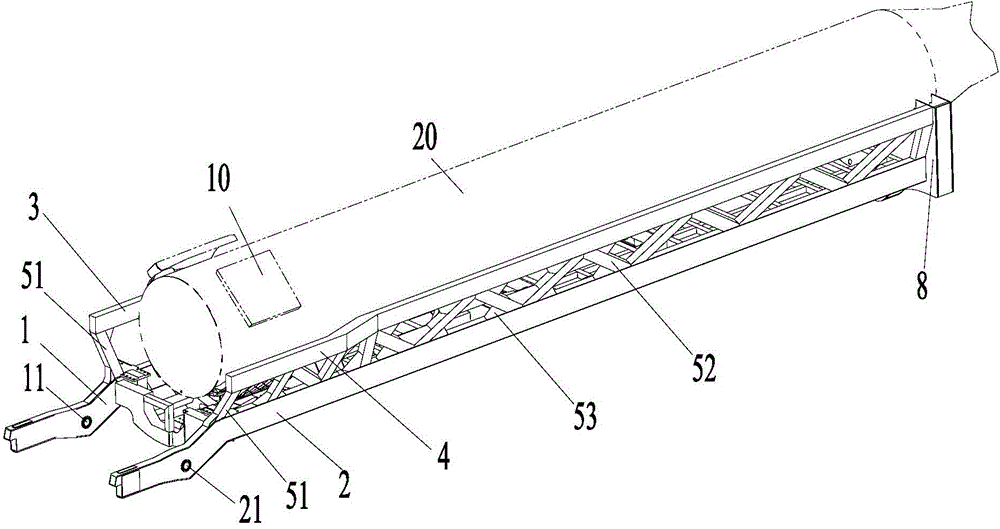

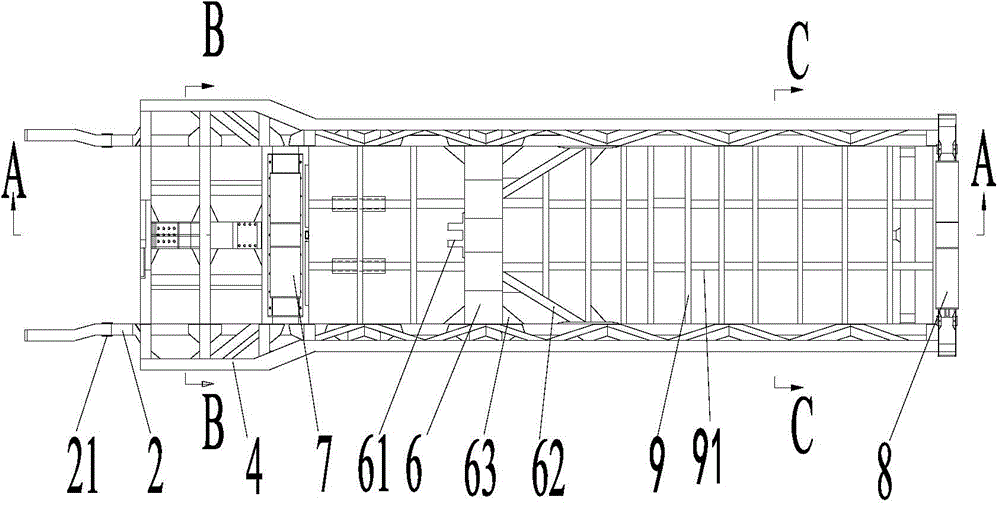

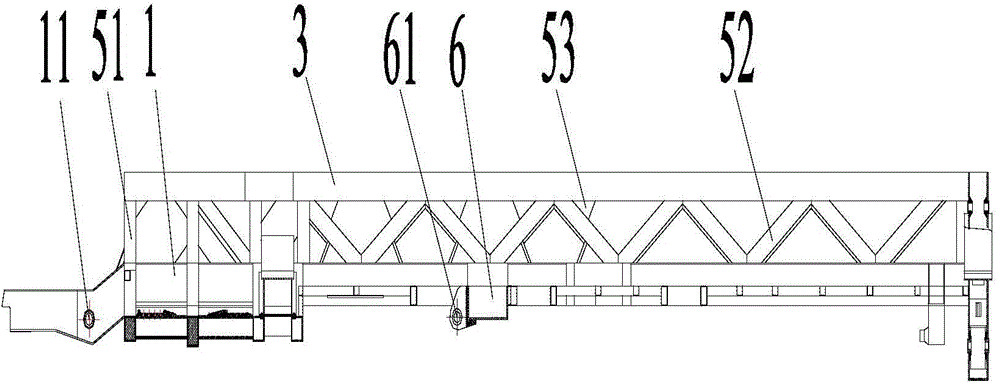

[0025] In order to solve the current lifting arm, the single-layer main beam structure is too bulky, and the shape and size of each part are mostly irregular. The gap between the lifting arm and the transported products is large, resulting in waste of space, which is not conducive to the equipment compartment and other other parts of the vehicle. To solve problems such as system layout, the present invention provides a truss type erecting arm.

[0026] The truss-type erecting arm includes: left lower main beam, right lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com