Curve distribution type shock wave automatic target scoring system

A distributed, shock wave technology, applied in target indication systems, moving targets, targets, etc., can solve the problems of misalignment of calculation centers, increase calculation errors and offsets of target reporting equipment, and improve work reliability and improve The effect of waveform acquisition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

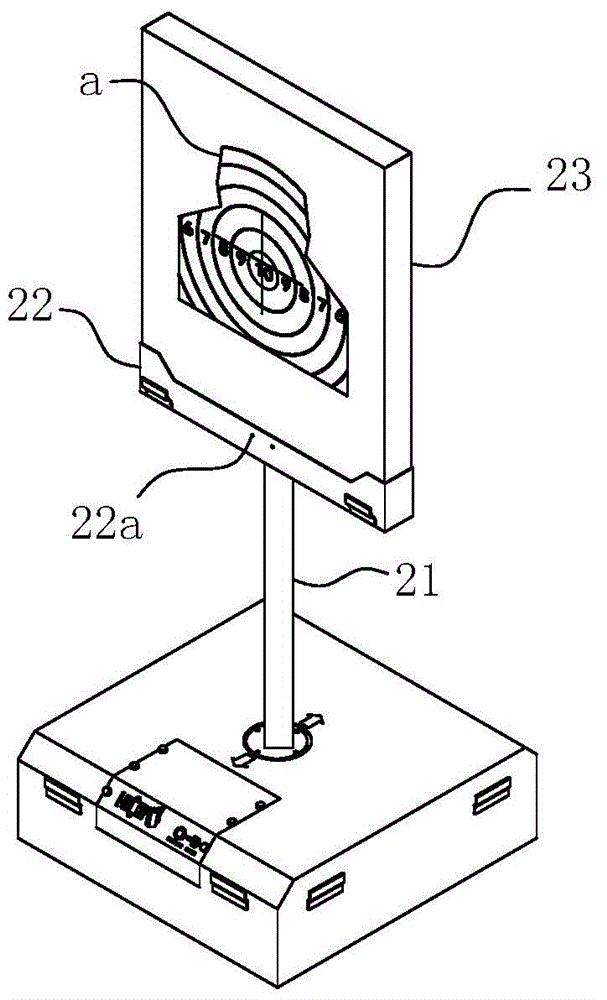

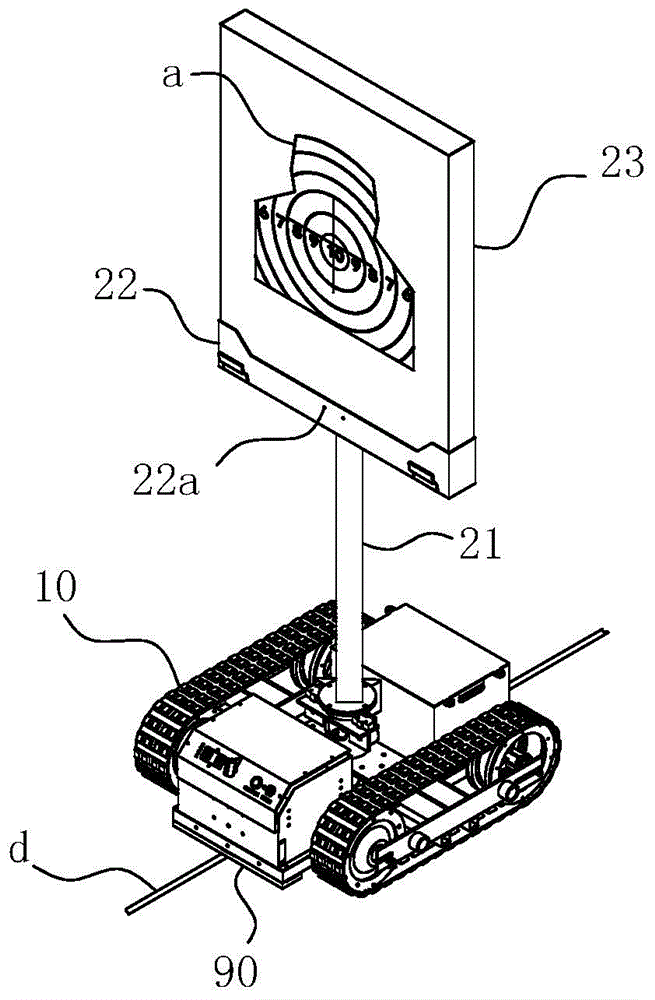

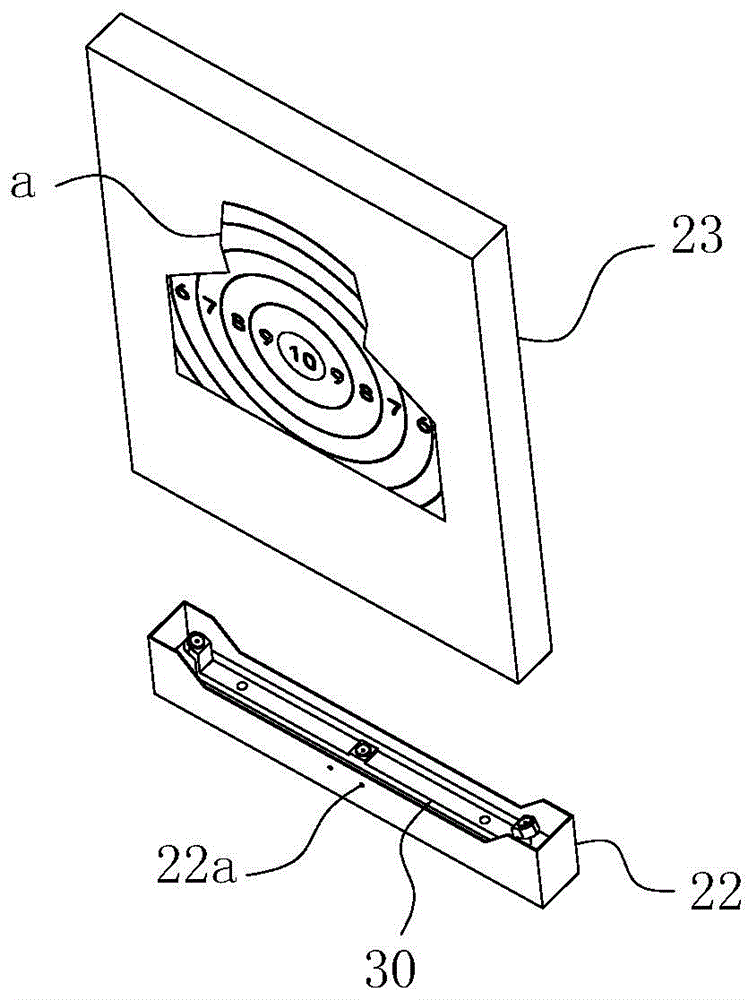

[0061] For ease of understanding, the attached Figure 1-21 Concrete testing device of the present invention and operation process thereof are further described as follows:

[0062] The specific structure of the present invention is as Figure 1-18 As shown, it takes the traveling mechanism 10 and the target frame assembly arranged on the traveling mechanism 10 as the main body, and is matched with a magnetic strip a that can be laid at will or embedded in the ground. The magnetic induction part 90 is also the magnetic sensor, through the control of the information control terminal, so as to realize the self-propelling purpose of the traveling mechanism 10 to find the magnetic track-find the magnetic track-align the magnetic track.

[0063] In order to further enhance the adaptability of the present invention, as Figure 15-18As shown, the present invention is also provided with a rotatable target surface structure at the target frame assembly. It utilizes the rotational co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com