Connector tail accessory and adhering sleeve

A technology of tail accessories and connectors, which is applied in the optical field, can solve problems such as the failure of optical cable connections and the inability to guarantee bonding sleeves, and achieve the effects of improving the sealing effect and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

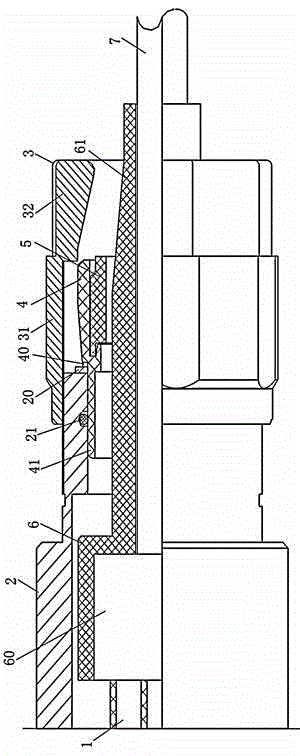

[0020] Embodiment 1 of the connector tail attachment of the present invention: as figure 1 As shown, it includes a combination sleeve 2 that extends forward and backward. There is a cavity extending forward and backward inside the combination sleeve. The plug is connected, and the front end of the bonding sleeve has a glue injection cavity 60, and the glue injection in the glue injection cavity can fix the optical fiber and the outdoor optical cable. The stepped surface of the bonding sleeve is used to stop and cooperate with the rear end surface of the bonding sleeve to prevent the bonding sleeve and the outdoor optical cable from protruding from the rear end of the bonding sleeve. The rear end of the bonding sleeve is also integrally connected with an extension section 61 extending backward. The middle part is provided with a front and rear through hole through which the outdoor optical cable can extend from the rear end of the extension section into the glue injection cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com