Submerged arc furnace low-pressure filtering energy-saving cabinet with push-pull type reactance handcart

A mobile, handcart-resistant technology, applied to harmonic reduction devices, AC networks to reduce harmonics/ripples, reactive power compensation, etc., can solve problems such as inconvenient maintenance operations, poor heat dissipation, and reduced workload. Achieve the effects of stable and smooth movement, strong service life, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

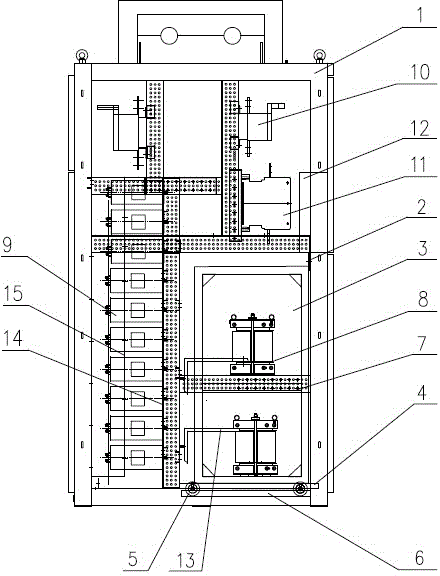

[0022] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

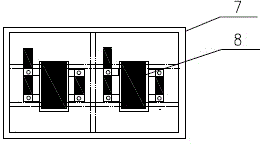

[0023] Refer to attached figure 1 and Figure 7 As shown, the submerged arc furnace low-voltage filter energy-saving cabinet with a push-pull mobile reactance handcart of the present invention includes a cabinet body 1, and a capacitor group 9 and a reactor group 8 are arranged in the cabinet body 1, and each reactor of the reactor group 8 is divided into The first layer is set in the push-pull mobile handcart 3, the reactor group 8 is led to the door-type mobile terminal box 12 through the detachable connection copper bar 13 through the fuse isolator 10 and the vacuum contactor 11, and the push-pull mobile handcart 3. It is movably arranged in the cabinet body 1 through the pulley slide rail mechanism.

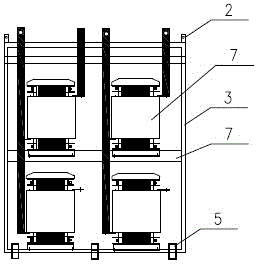

[0024] refer to figure 2 , image 3 As shown, the push-pull mobile handcart 3 includes a hollow frame, and at least two layers of reactor sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com