Self-propelled sprinkler irrigation machine and sprinkler irrigation method for greenhouse

A sprinkler and self-propelled technology, applied in greenhouse cultivation, botanical equipment and methods, climate change adaptation, etc., can solve the problem of greenhouse supporting steel frame, complex truss structure design, high structural strength requirements of greenhouses, and sprinkler work. problems such as low efficiency, to achieve the effect of wide practicability, small space, and reduced structural strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

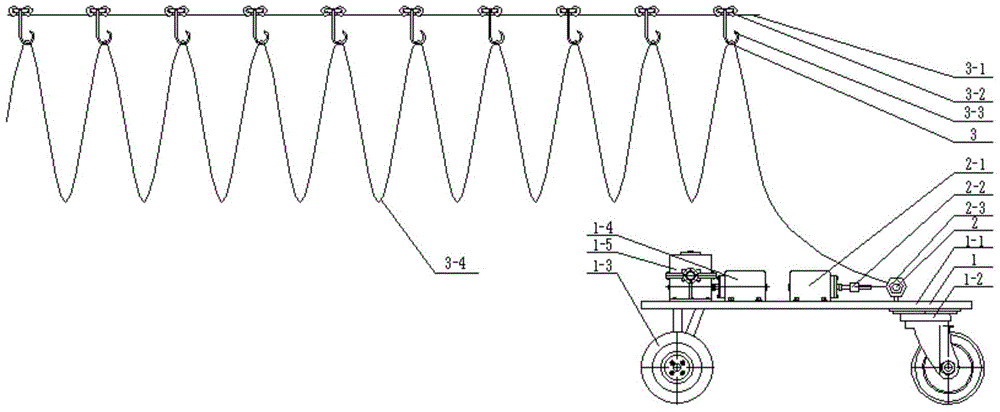

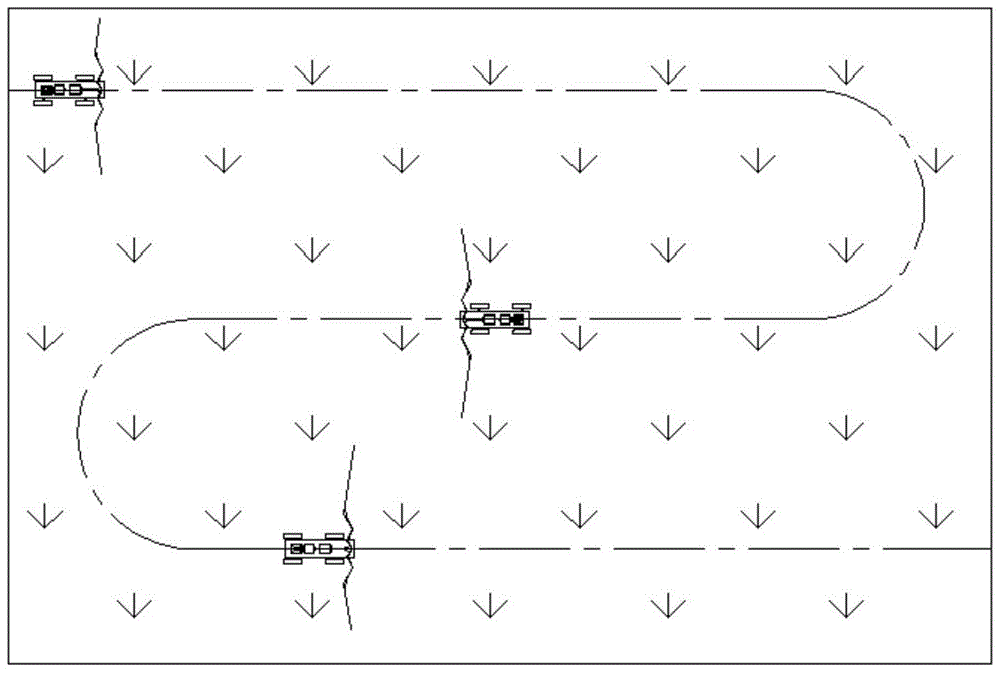

[0020] figure 1 As shown, the greenhouse self-propelled sprinkler irrigation machine of the present invention is mainly composed of a host 1, a retractable and foldable truss nozzle 2, a cable, and a water hose carrying device 3; The hose is finally sprayed out through the nozzle to complete the entire sprinkler operation.

[0021] Described main frame 1 comprises vehicle frame 1-1, universal front wheel 1-2, driving rear wheel 1-3, driving motor one 1-4 and speed reducer 1-5; Described universal front wheel 1-2 The driving rear wheel 1-3 is fixedly connected under the vehicle frame 1-1, and the driving motor 1-4 and the speed reducer 1-5 are fixedly connected and installed on the vehicle frame, and are connected with the driving rear wheel 1-3 through a chain transmission;

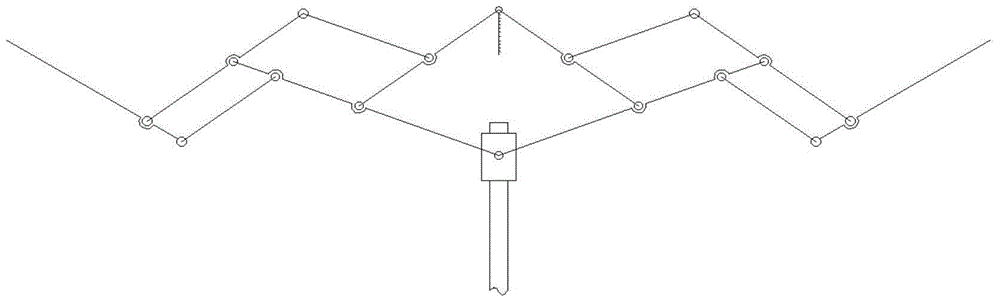

[0022] The telescopic foldable truss nozzle 2 includes a drive motor 2-1, a lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com