Method for carrying out liquid fermentation to produce pu'er tea powder employing fresh leaves as raw material

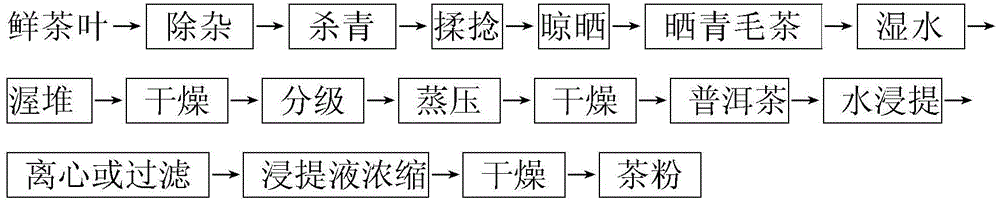

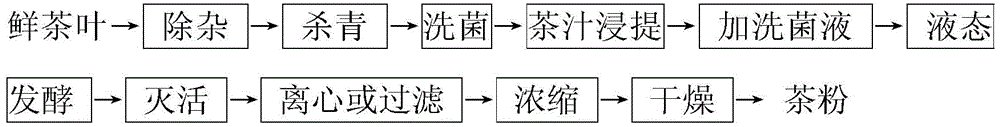

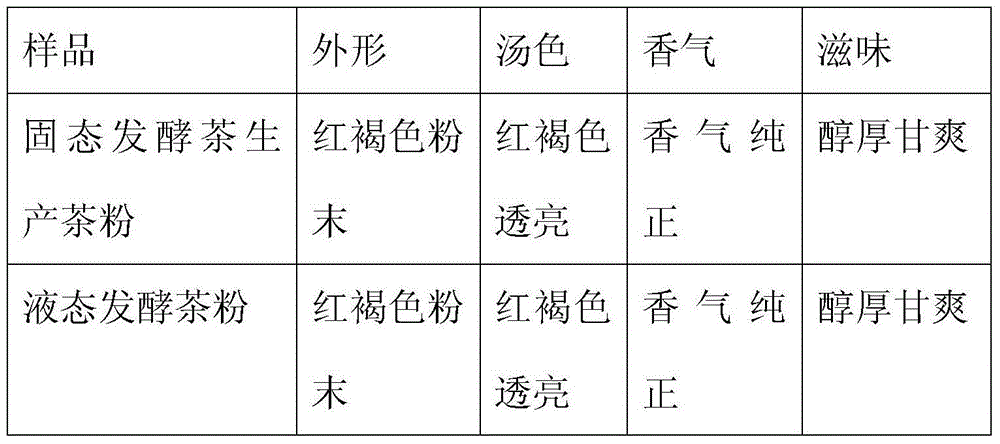

A technology of liquid fermentation and Pu-erh tea, applied in the direction of tea extraction, can solve the problems of inability to automatically control the fermentation process, unstable product quality, long fermentation cycle, etc., and achieve the effects of high degree of automation, reduced labor intensity and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Take 500g of fresh Pu-erh tea leaves. Firstly, wash the fresh leaves according to fresh tea leaves: water = 5:10 (weight to volume ratio). The roasted tea leaves are directly pulverized. Add distilled water to the crushed green leaves according to the ratio of tea to water 5:30 (after green tea: water, weight-to-volume ratio), stir well, boil at normal pressure for 2 times, each time for about 5 minutes, and filter through filter cloth to obtain the boiling extract of tea leaves. After the boiling extract is cooled to room temperature, add the bacteria washing liquid, mix and stir evenly for liquid fermentation, the fermentation temperature is 30°C, the fermentation time is about 4 days, and then the temperature is adjusted to 50°C for 2 days of fermentation, and the fermentation liquid is obtained after the fermentation is completed. The obtained fermented liquid was sterilized by boiling water for 5 minutes, centrifuged at 10,000 rpm for 10 minutes to obtain fermented...

Embodiment 2

[0050] Take 500g of fresh Pu’er tea leaves, first wash the fresh leaves according to fresh tea leaves: water = 3:10 (weight to volume ratio), after washing the fresh leaves, remove the green leaves, and remove the green leaves in a boiling water bath for 15 seconds, take them out and dry the fresh leaves Surface moisture back up. The tea leaves after fishing are directly crushed. Add distilled water to the crushed green leaves according to the ratio of tea to water 3:30 (after green tea: water, weight-to-volume ratio), stir well, boil at normal pressure for about 10 minutes, and filter through a filter cloth to obtain the boiling extract of tea leaves. After the boiling extract is cooled to room temperature, add the bacteria washing solution, mix and stir evenly for liquid fermentation, the fermentation temperature is 40°C, the fermentation time is about 5d, and the temperature is adjusted to 60°C for 3d fermentation, and the fermentation liquid is obtained after the fermentatio...

Embodiment 3

[0052] Take 500g of fresh Pu’er tea leaves, first wash the fresh leaves according to fresh tea: water = 6:10 (weight to volume ratio), steam the fresh leaves after washing, steam the greens in a boiling water bath for 30 seconds, take them out and dry the fresh leaves Surface moisture back up. The steamed tea leaves are directly pulverized. Add distilled water to the crushed green leaves according to the ratio of tea to water 6:30 (after green tea: water, weight-to-volume ratio), stir well, boil at normal pressure for about 8 minutes, and filter through filter cloth to obtain tea extract. After the boiling extract is cooled to room temperature, add the bacteria washing liquid, mix and stir evenly for liquid fermentation, the fermentation temperature is 50°C, the fermentation time is about 7d, and the temperature is adjusted to 70°C for 4d fermentation, and the fermentation liquid is obtained after the fermentation is completed. The obtained fermented liquid was sterilized by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com