Artificial bear bile powder and quality evaluation method thereof

A kind of bear bile powder, artificial technology, applied in the field of biology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] 1 The effect of the secondary seed medium on the growth curve

[0097] 1) Apply the engineering bacteria stored in the -80°C refrigerator to the LB solid plate medium containing 100 mg / L ampicillin by streaking method, and activate and culture at 37°C for 12 hours;

[0098] The composition of the LB solid medium is as follows: tryptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L, agarose 15.0g / L.

[0099] 2) Pick a single colony from the LB solid plate medium, inoculate it in the LB liquid medium supplemented with 100mg / L ampicillin, and culture it with shaking at 225rpm and 37°C for 9 hours to obtain the first-grade seeds;

[0100] The composition of described LB liquid medium is as follows: tryptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L;

[0101] 3) Inoculate the above culture into 2-YT liquid medium and the same LB liquid medium as described in 2) at a ratio of 1:20, culture with shaking at 225rpm / min and 37°C, and measure both Growth curve;

[010...

Embodiment 2

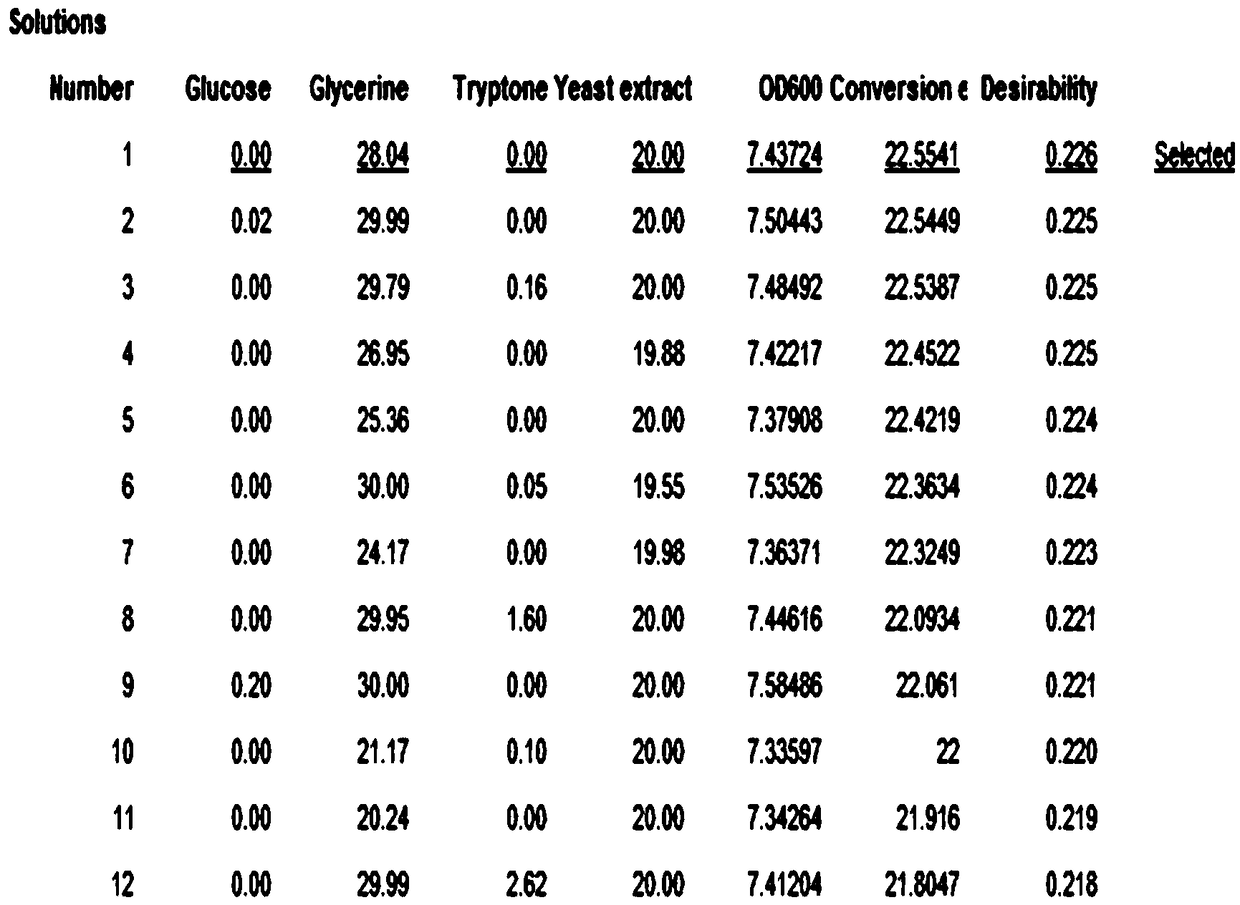

[0107] Optimization experiment of M9-GY optimized medium

[0108] 1) Apply the design method of Box-Behnken Design in the Design-Expert.V8.0.6.1 software, based on the composition of the M9 basic medium, design a test with glucose, glycerol, yeast extract and tryptone as four factors, Glucose, yeast extract, and tryptone all choose the three levels of 0, 10, and 20g / L, and glycerol chooses the three levels of 0, 15, and 30ml / L. The OD600 and conversion rate are used as the investigation indicators at the same time. The 29 groups of programs designed by the software and The results are as follows:

[0109]

[0110] 2) The specific fermentation process is as follows: Obtain first-grade seeds according to the operation in Example 1, inoculate the first-grade seeds into liquid 2-YT medium at a ratio of 1:20, and shake and culture at 225rpm and 37°C for 4 hours to obtain 2-YT. Grade seeds; the second grade seeds are inoculated into the above-mentioned various liquid mediums in ...

Embodiment 3

[0114] Optimization of induction culture phase

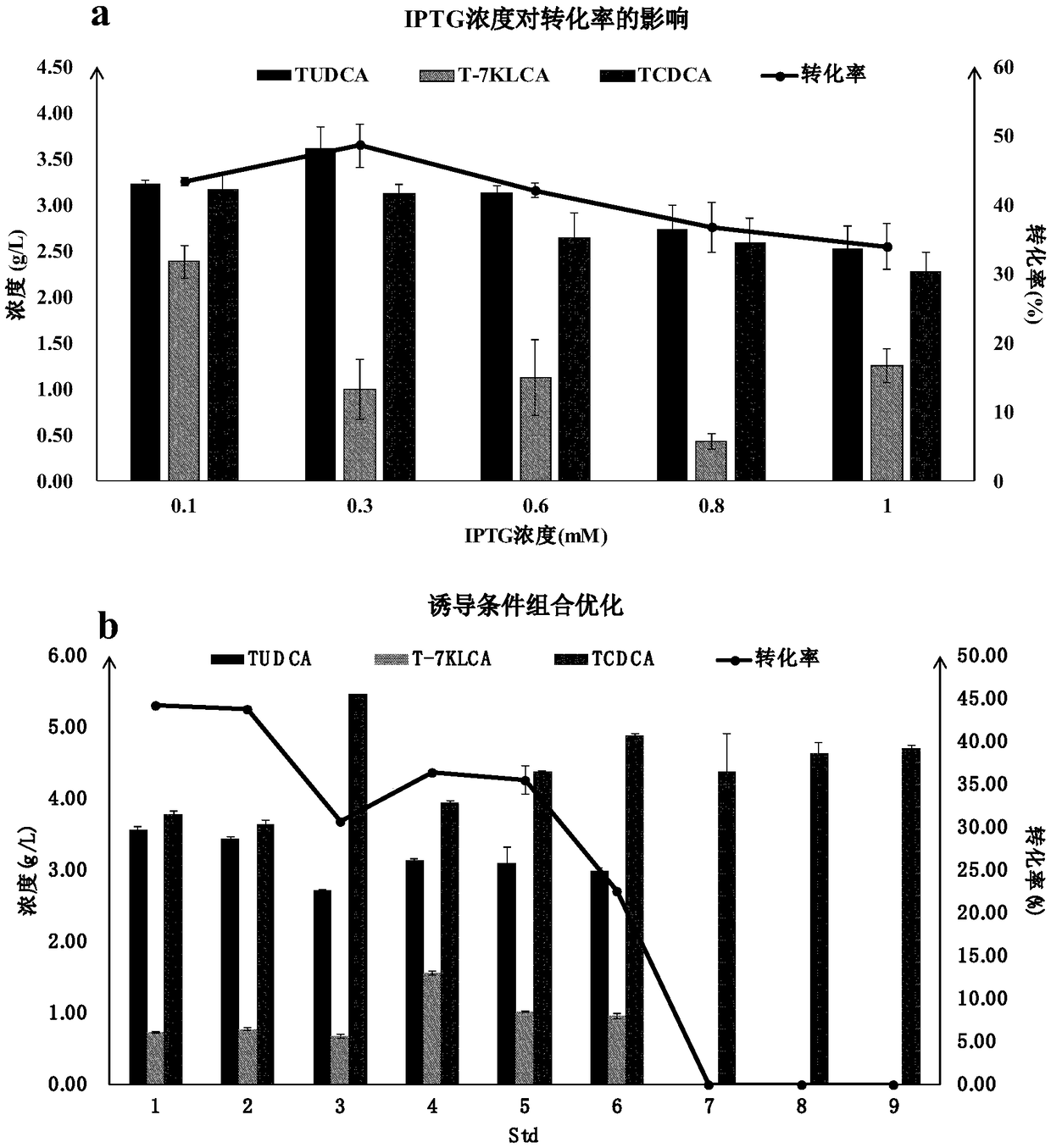

[0115] 1 Effect of IPTG concentration on conversion rate

[0116] 1) According to the operation in Example 1, the first-grade seeds were obtained, and the first-grade seeds were inoculated into the liquid 2-YT medium at a ratio of 1:20, and cultured with shaking at 225 rpm and 37° C. for 4 hours to obtain the second-grade seeds;

[0117] 2) Inoculate the secondary seeds into the M9-GY optimized medium liquid medium at a ratio of 1:20, in triplicate, and shake and culture at 225rpm and 37°C for 5 hours;

[0118] 3) Add IPTG to the final concentration of 0.1, 0.3, 0.6, 0.8, 1.0mM respectively, shake and culture at 225rpm, 30°C for 3 hours; Shake culture at 25°C for 6 hours for fermentation; the results are as follows figure 1 as shown in a:

[0119] 2. Combination optimization of induction conditions

[0120]Select the pre-log (4 hours), mid-log (5.5 hours), and late log (7.5 hours) of the growth curve of the recombinant engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com