Non-live bacterium type whey milk-containing drink and preparation method thereof

A technology for milk-containing beverages and whey, applied in whey, dairy products, Streptococcus/Lactococcus, etc., can solve the problems of product taste improvement, low protein content, complicated process, etc., to achieve shelf life, reduce production costs, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

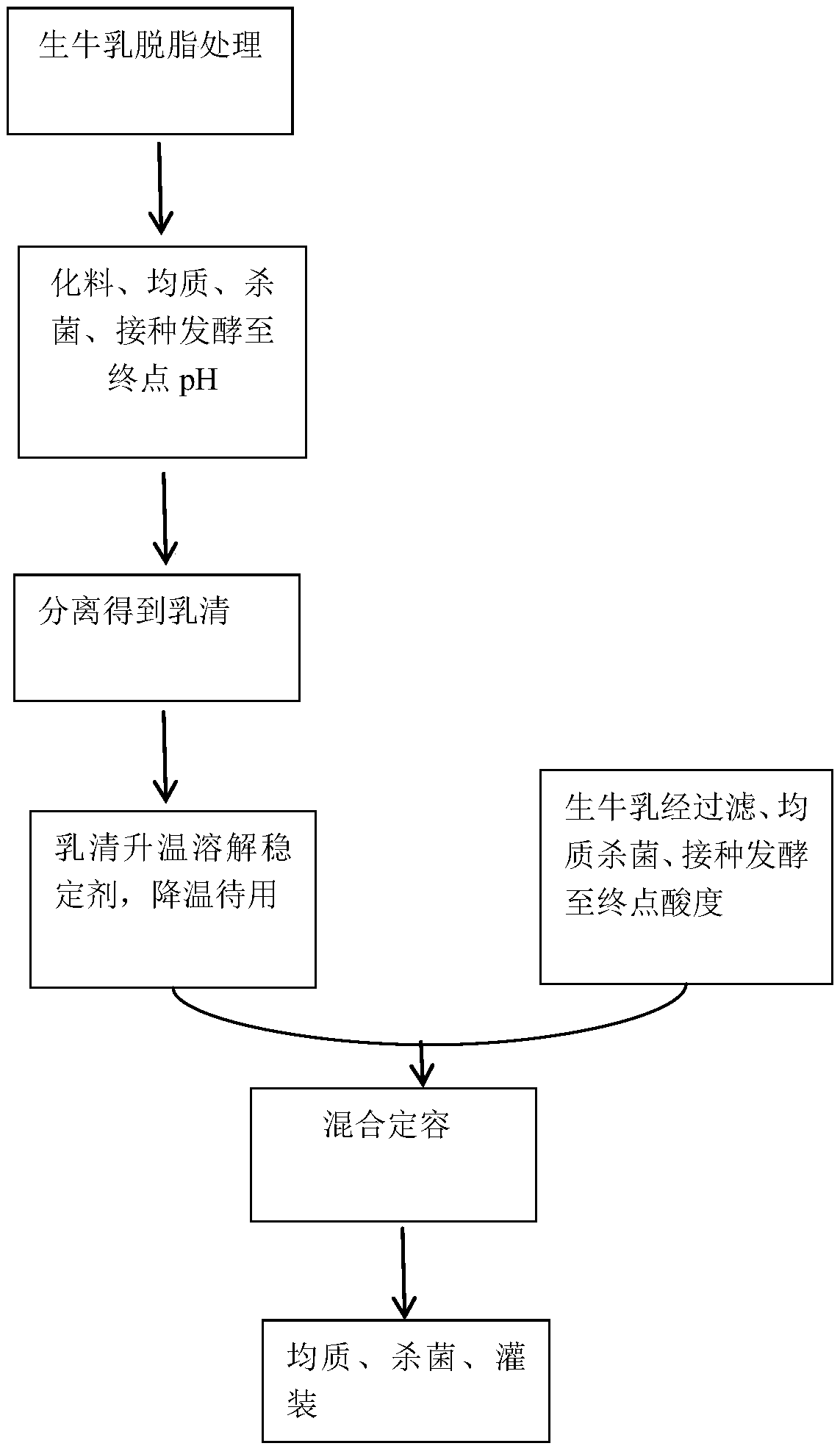

Method used

Image

Examples

Embodiment 1

[0057] A preparation method of non-viable whey milk-containing beverage includes the following steps:

[0058] (1) Preparation of whey, the following parts are parts by weight:

[0059] Skim the raw milk to make the fat content between 1.2% and 1.5%. Take part of the skim milk and heat it up to 52°C. Add 40 parts of white sugar and cut for 5 minutes. Add the remaining skim milk to make the volume up to 1000 parts. Filter and homogenize, homogenization temperature is 60℃, homogenization pressure 15-16Mpa, sterilization, sterilization temperature 95℃, sterilization time 300s, after sterilization, cool to 38℃, inoculate starter A, terminate pH 4.6, demulsify and stir for 200s After passing through the separator, the separator has a flow rate of 3.0 tons / hour and a smoothing pump speed of 20%. The obtained Greek yogurt is cooled to 23°C and enters into a tank for filling. The outlet temperature during whey separation is 35°C, and the whey is directly converted into feed.

[0060] The pr...

Embodiment 2

[0074] A preparation method of non-viable whey milk-containing beverage includes the following steps:

[0075] (1) Preparation of whey, the following parts are parts by weight:

[0076] The raw milk is skimmed to make the fat content 1.8%-2.0%. Take part of the skim milk and heat it to 54°C. Add 50 parts of white sugar and cut for 10 minutes. Add the remaining skim milk to make the volume to 1000 parts, then filter, Homogenization, homogenization temperature is 70℃, homogenization pressure 15-16Mpa, sterilization, sterilization temperature 94℃, sterilization time 300s, after sterilization, cool to 40℃, inoculate starter A, terminate pH 4.7, demulsify and stir for 200s, after Separator, the separator has a flow rate of 2.8 tons / hour and a smoothing pump speed of 20%. The obtained Greek yogurt is cooled to 23°C and put into cans. The outlet temperature during whey separation is 40°C, and the whey is directly fed into the whey tank for later use.

[0077] The protein content of the ra...

Embodiment 3

[0091] A preparation method of non-viable whey milk-containing beverage includes the following steps:

[0092] (1) Preparation of whey, the following parts are parts by weight:

[0093] The raw milk is skimmed to make the fat content between 1.5% and 1.7%. Take part of the skim milk and heat it to 55°C. Add 40 parts of white sugar and cut for 5 minutes. Add the remaining skim milk to make the volume up to 1000 parts, then filter, Homogenize, homogenization temperature is 65℃, homogenization pressure 15-16Mpa, sterilization, sterilization temperature 95±2℃, sterilization time 300s, after sterilization, cool to 40℃, inoculate starter A, terminate pH 4.6, demulsify and stir for 200s After passing through the separator, the separator has a flow rate of 3.1 tons / hour and a smoothing pump speed of 20%. The Greek yogurt is cooled to 23°C and placed in the tank. The temperature of the whey separation is 33°C, and the whey is directly fed into the whey tank.

[0094] The protein content of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com