Intelligent floor brush device of dust collector

A vacuum cleaner, intelligent technology, applied in the direction of suction nozzles, etc., can solve problems such as potential safety hazards, and achieve the effect of convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

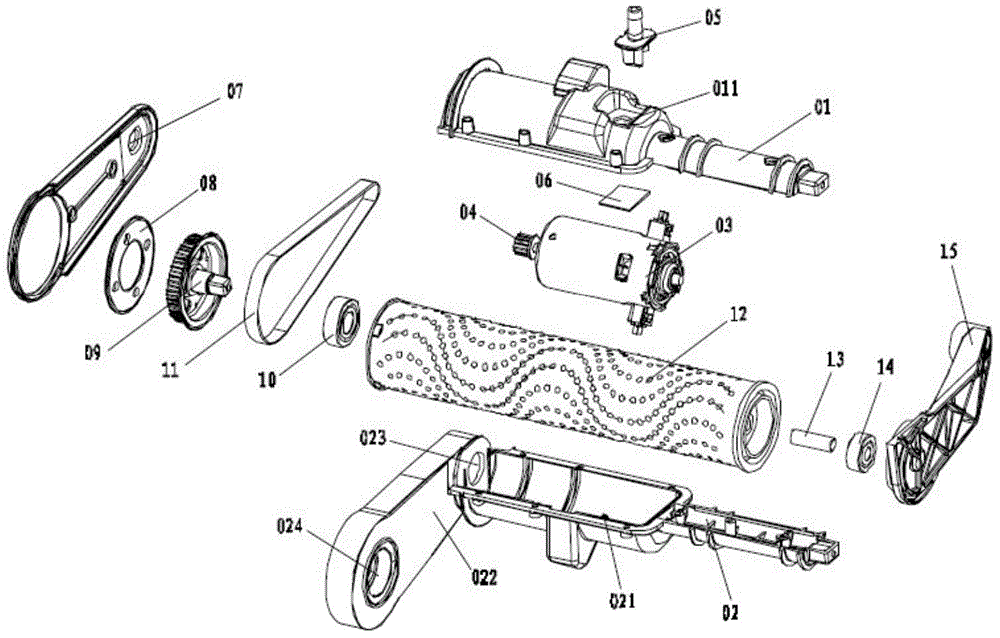

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

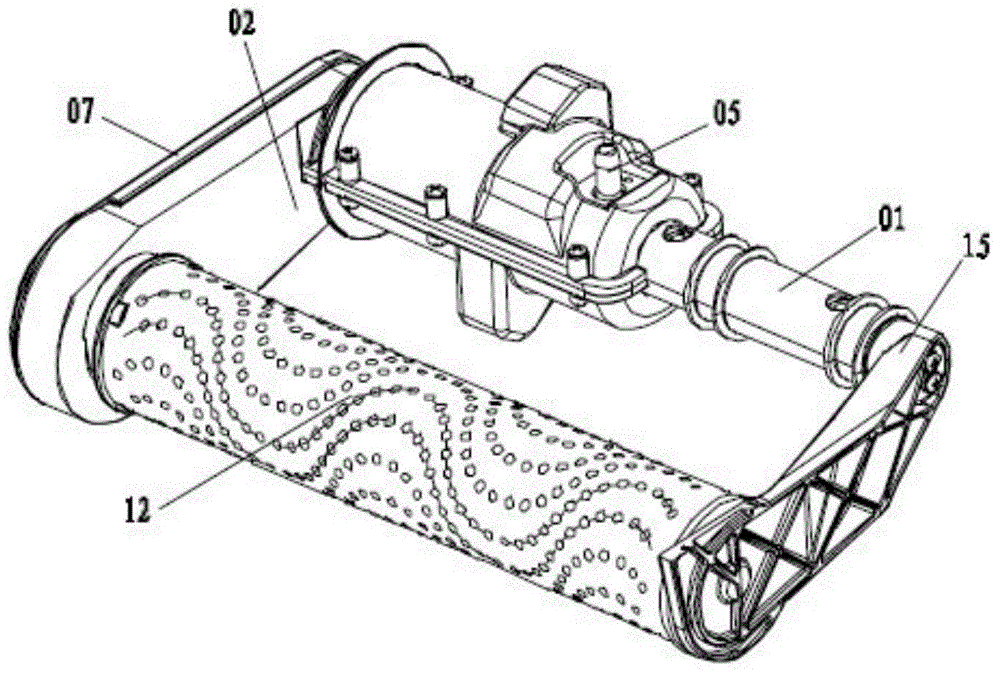

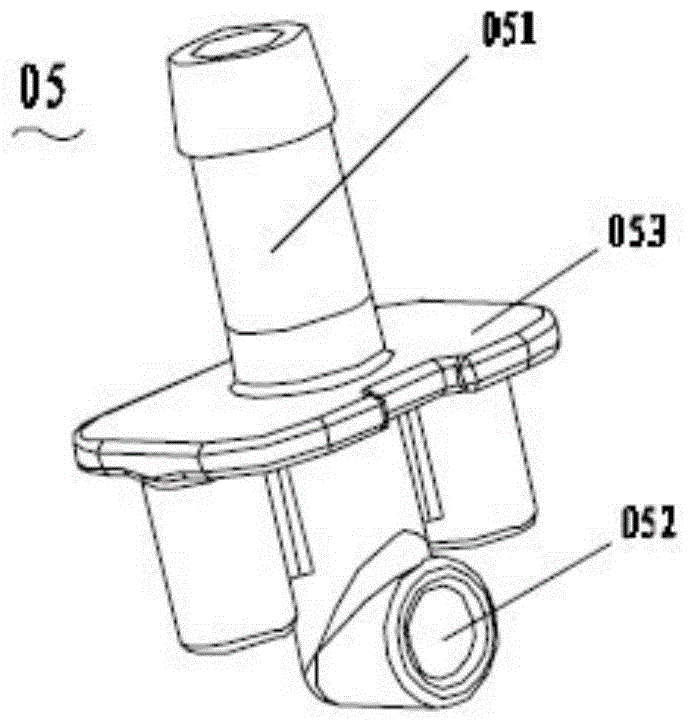

[0018] Such as Figure 1-4 As shown, the present invention provides a vacuum cleaner intelligent brushing device, including:

[0019] The lower housing 02 includes a lower motor cover 021 and a right cover plate 022 affixed to the lower motor cover 021, the right cover plate 022 is provided with a shaft hole 023 and a through hole 024 side by side, and the through hole 024 A left bearing 10 is fixed inside;

[0020] Upper motor cover 01, which is arranged in cooperation with the lower motor cover 021, the upper part of the upper motor cover 01 is provided with an air outlet 011, and the side part of the upper motor cover 01 is provided with a wire hole (not shown);

[0021] The left cover plate 07 is arranged in cooperation with the right cover plate 022;

[0022] The driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com