Bulk coal crushing device and crushing process in medium-thick coal seam working face

A crushing device and large coal technology, applied in the direction of grain processing, etc., can solve the problem of coal blockage at the unloading point of the conveyor and the entrance point of the transfer machine, and achieve the effect of simple installation, fast mining and fast pushing, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Carry out the specific embodiment of the present invention in detail below in conjunction with accompanying drawing:

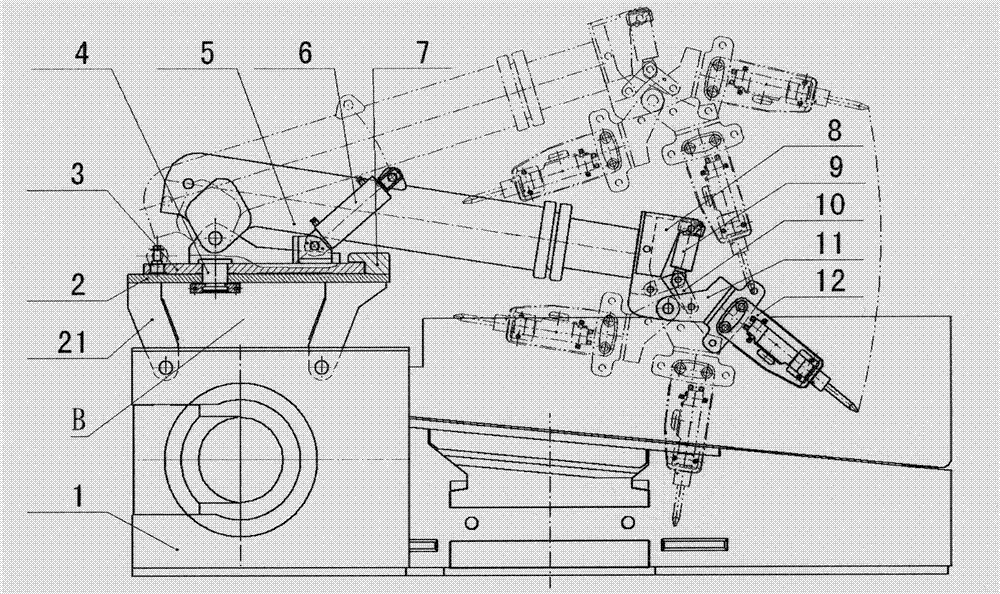

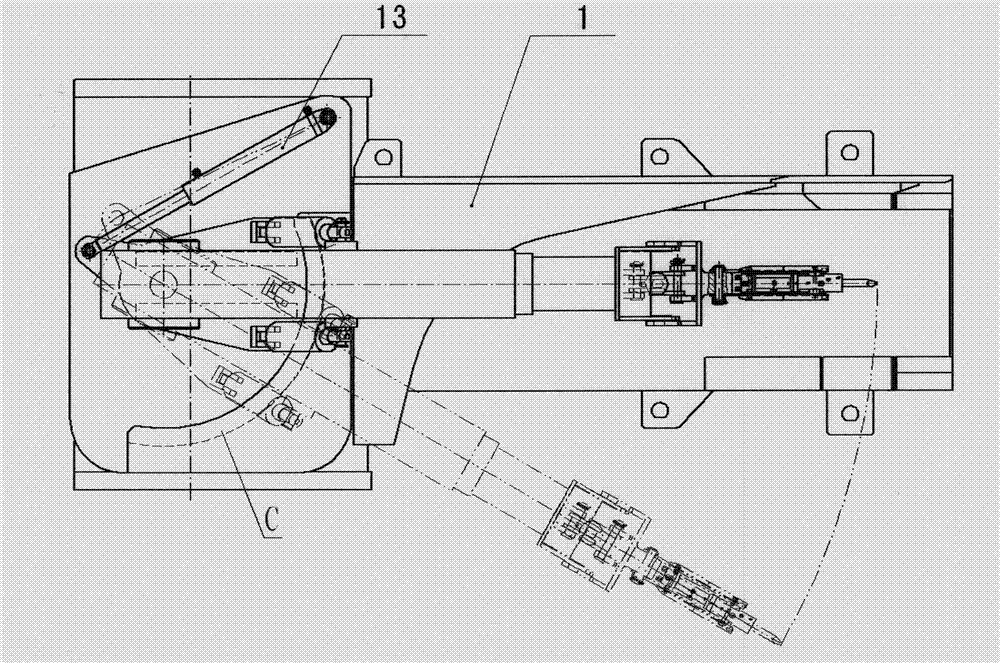

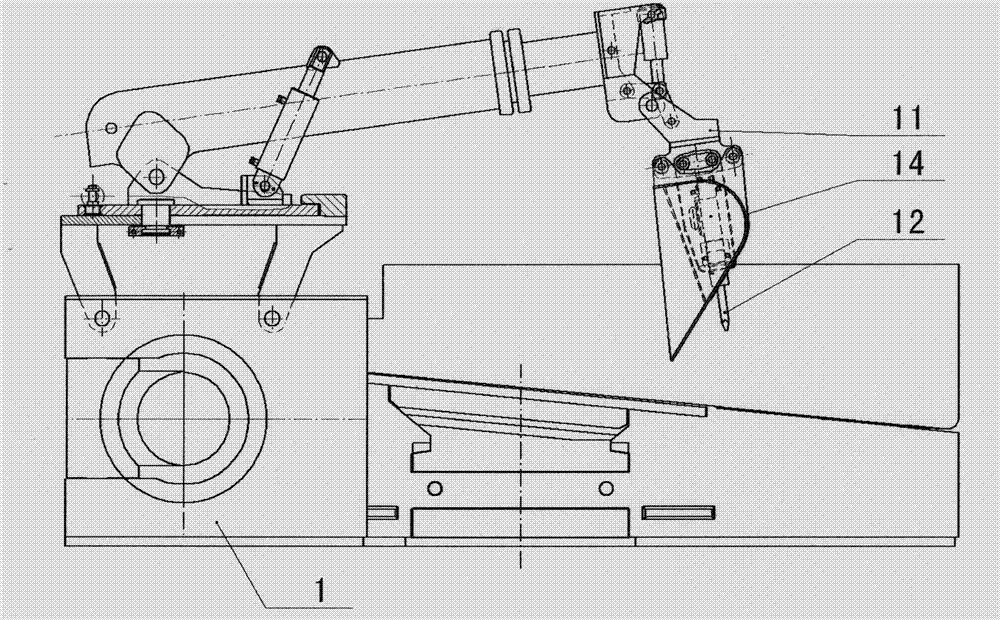

[0031] Such as Figure 1 to Figure 4 As shown, the large coal crushing device in the medium-thick coal seam working face includes a fixed base 2, a rotary seat 3, a rotary shaft 4, a rocker arm 5, a vertical swing cylinder 6, a briquetting block 7, a crushing fixed frame 8, and a hydraulic hammer attitude control cylinder 9. Small connecting rod 10, crushing turret 11, full hydraulic crushing hammer 12, horizontal swing oil cylinder 13, rake bucket 14, the support plate 21 on the fixed base 2 is fixed with the working surface conveying equipment 1 through the pin shaft, and there is a gap The cable space B is convenient for the layout of hydraulic pipelines, cables, control lines and other cables at the head; One end is clamped in the arc-shaped track groove C of the pressing block 7, the other end of the horizontal swing cylinder 13 is hinged to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com