Method for disassembling threaded ring of main steam valve

A threaded ring and main steam technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of laborious and time-consuming disassembly of threaded rings, increase preload force, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

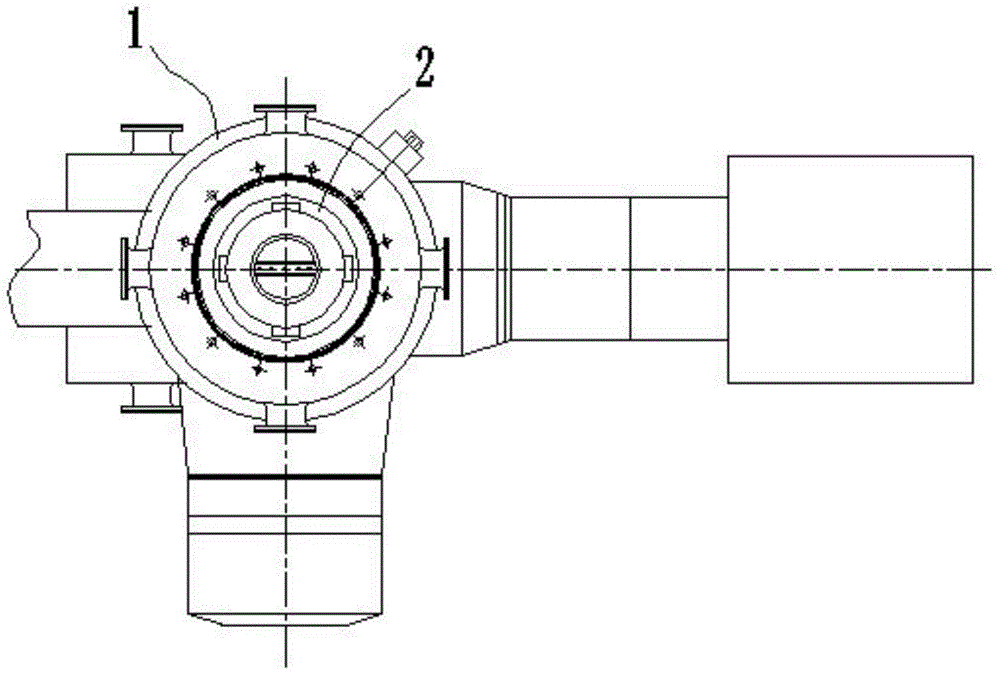

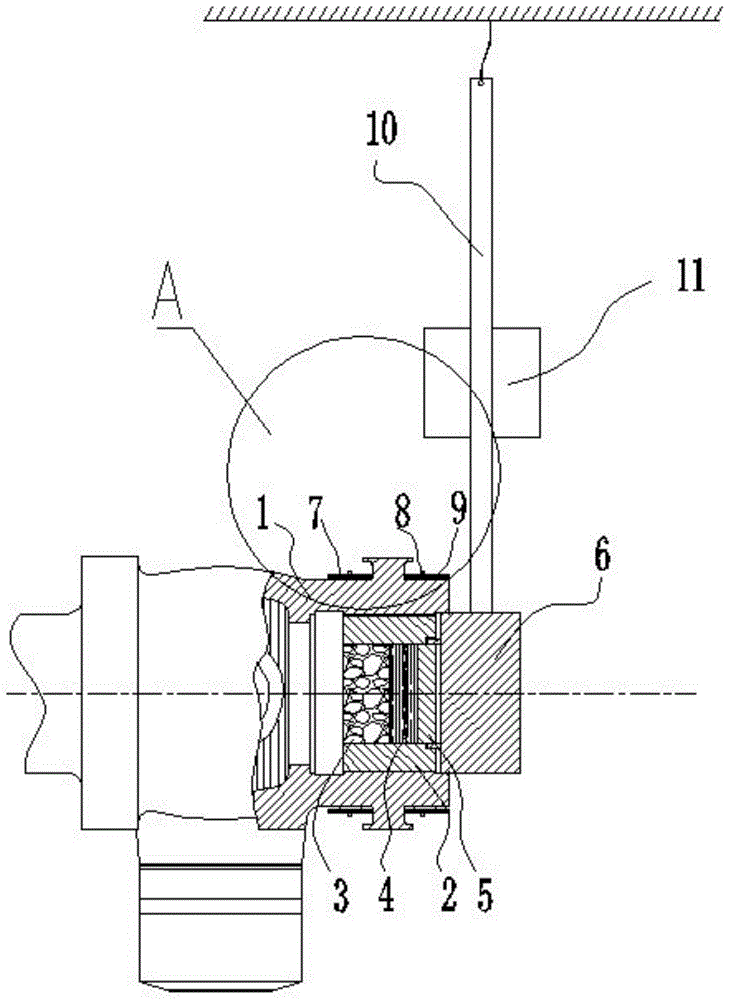

[0020] Such as figure 1 and figure 2 As shown, a method for removing the threaded ring of the main steam valve includes the following steps:

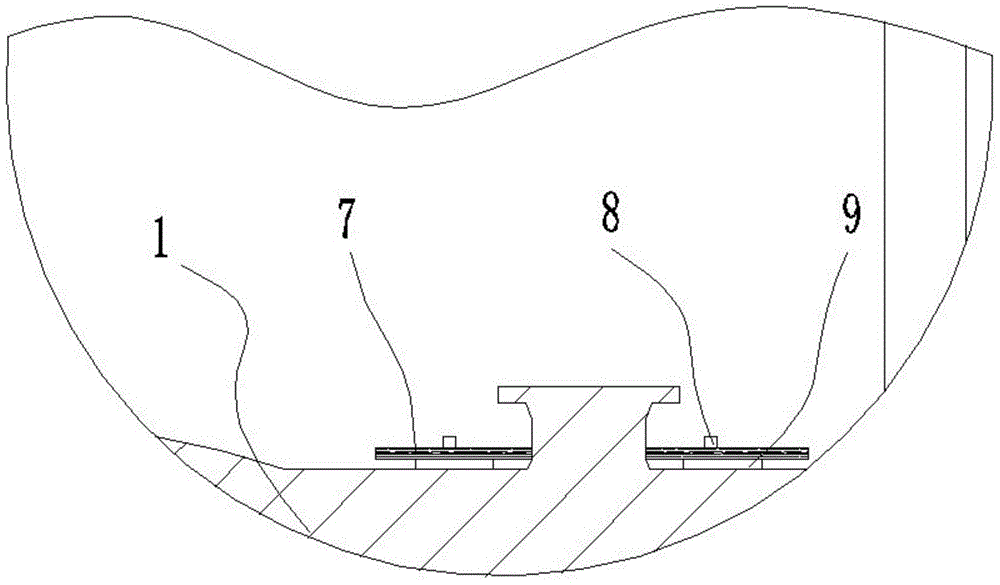

[0021] The first step is to lay a heating device on the outer surface of the valve housing 1, and arrange a number of temperature measuring elements evenly in the circumferential direction on the outer wall of the valve housing and under the heating device;

[0022] The second step is to evenly put refrigerated items in the inner chamber of the threaded ring 2, and evenly arrange a number of temperature measuring elements on the outer wall of the threaded ring;

[0023] The third step is to install the threaded ring special removal tool 6 on the removal port of the threaded ring side wall, and a booster rod 10 is fixed above the special removal tool, and the upper end of the booster rod is suspended on the crane spreader;

[0024...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com