Universal solar wing deployment frame for satellites with automatic horizontal adjustment

A level adjustment, solar technology, applied in the simulation devices of space navigation conditions, space navigation equipment, transportation and packaging, etc., can solve the problems of large space occupation, low precision adjustment efficiency, poor versatility, etc., to eliminate contact gaps, Guaranteed leveling effect and stability, the effect of eliminating redundant constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but these are only exemplary and not intended to limit the scope of protection thereof.

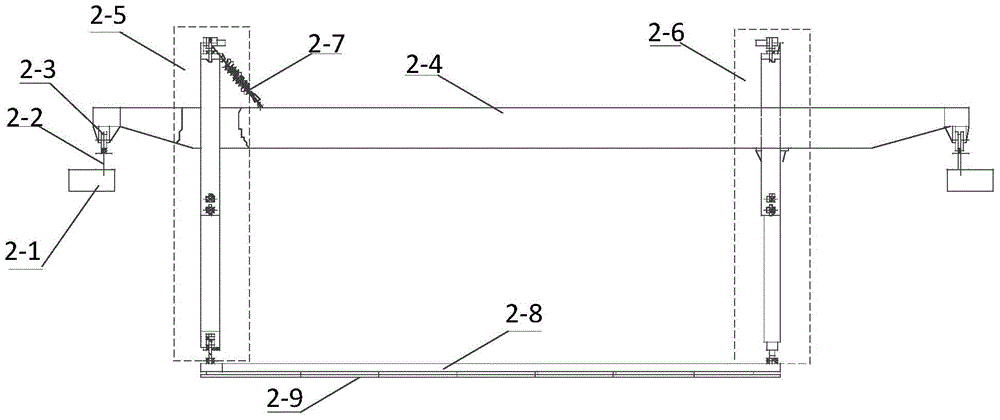

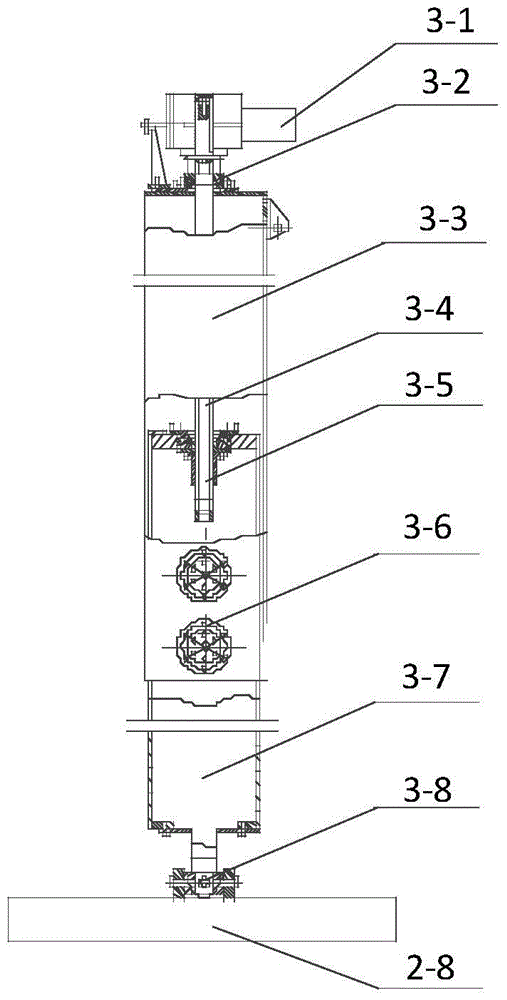

[0020] see figure 2 , figure 2 It is a schematic diagram of the structure of the automatic level-adjusting satellite universal solar wing deployment frame of the present invention. The satellite universal solar wing deployment frame is composed of a mechanical system and a control system. The mechanical system mainly includes two upper guide rails 2-2 and two sets of drive mechanisms 2 -3. Main beam 2-4, hinged telescopic mechanism 2-5, rigidly connected telescopic mechanism 2-6, spring 2-7, platform 2-8, bottom guide rail 2-9, the mechanical system of the solar wing deployment frame is fixed on the foundation Two upper guide rails 2-2 are respectively welded on the corbels 2-1 provided on both sides of the facility; the upper guide rails 2-2 and the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com