Sampling needle driving mechanism for biochemical analyzer

A technology of biochemical analyzer and driving mechanism, which is applied in the field of medical testing, can solve problems such as the difficulty of accurate sampling of sampling needles, the shaking of the rocker-driven slider, and the inability to position horizontally, so as to reduce costs, move smoothly, and improve sampling accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

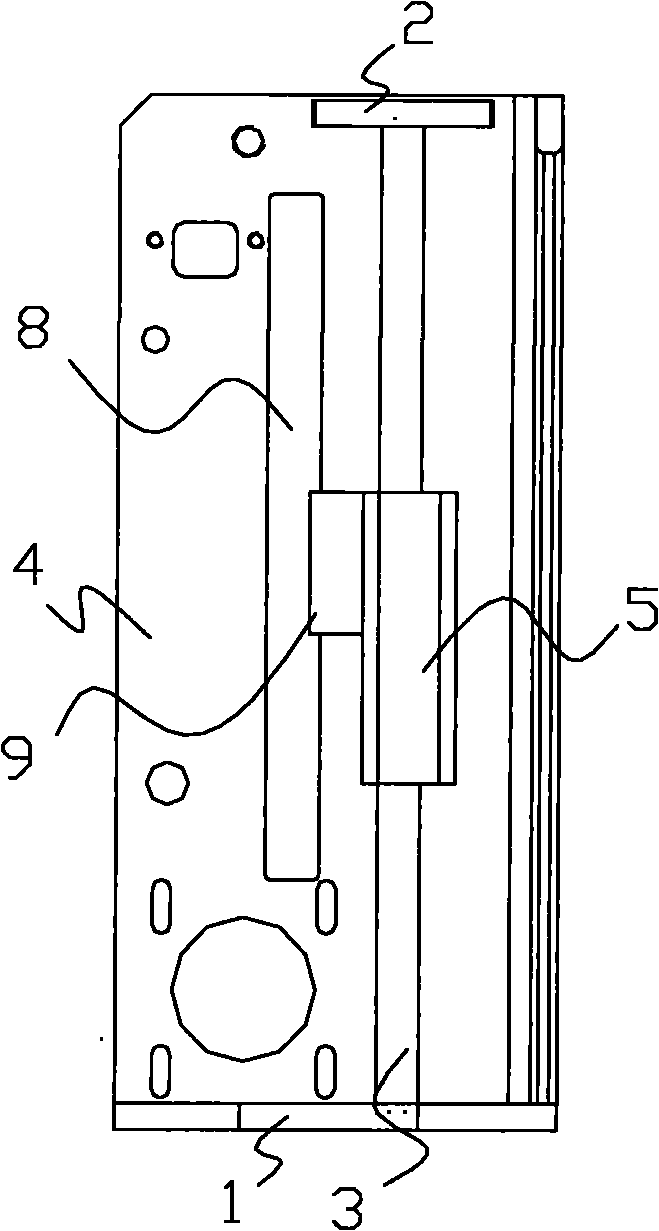

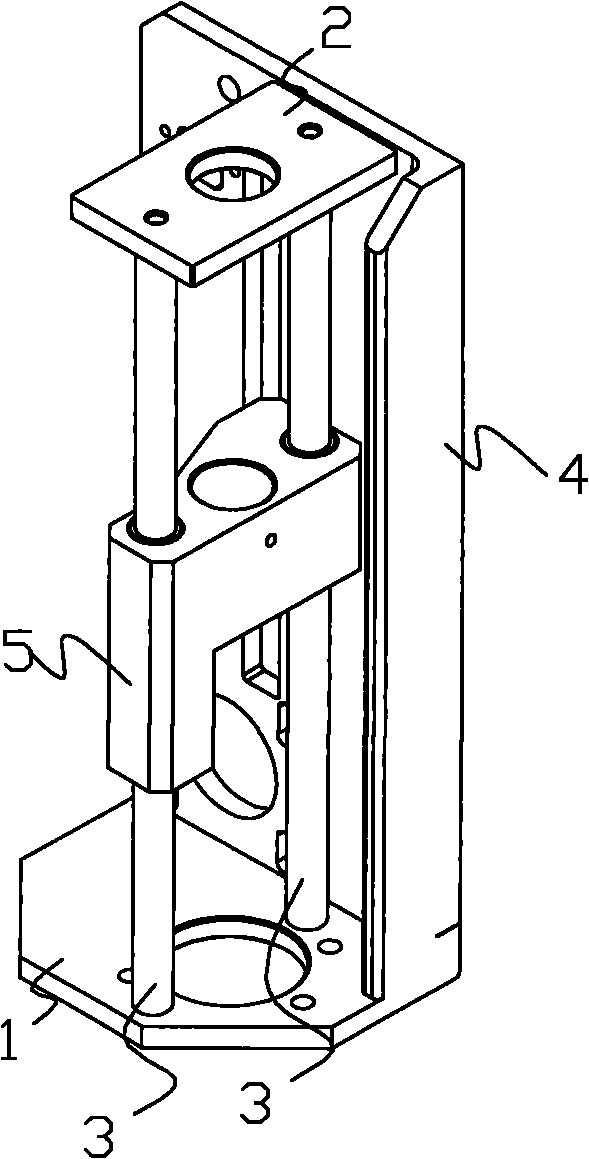

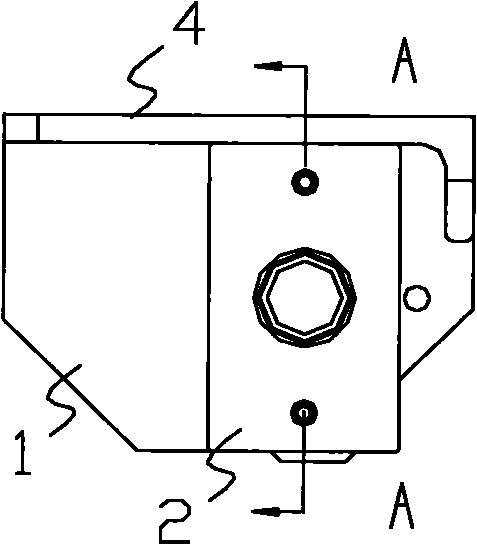

[0020] The sampling needle driving mechanism of the biochemical analyzer of this embodiment is as follows: Figure 1-4 As shown, the sampling needle driving mechanism for the biochemical analyzer includes a base 1, a limit baffle 2, a guide shaft 3, a vertical plate 4, and a rocker driving slider 5. The vertical plate 4 is arranged on one side of the base 1, The guide shaft 3 is arranged on the base, and the guide shaft 3 and the riser 4 are parallel to each other and perpendicular to the base 1 . The rocker arm driving slider 5 is used to drive the rocker arm of the sampling needle to move, and a guide hole 6 corresponding to the guide shaft is arranged on it, and a shaft sleeve 7 is arranged in the guide hole 6, and the rocker arm driving slider 5 is connected with the guide shaft through the shaft sleeve 7. Shaft 3 has a small interference fit. In addition, there is a fixed guide groove 8 on the vertical plate 4 in the same direction as the guide shaft 3. The rocker arm dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com