Method and device for rolling up planar products

A product, flat technology, applied in the field of rolling flat products, can solve the problems of deformed surface, damage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

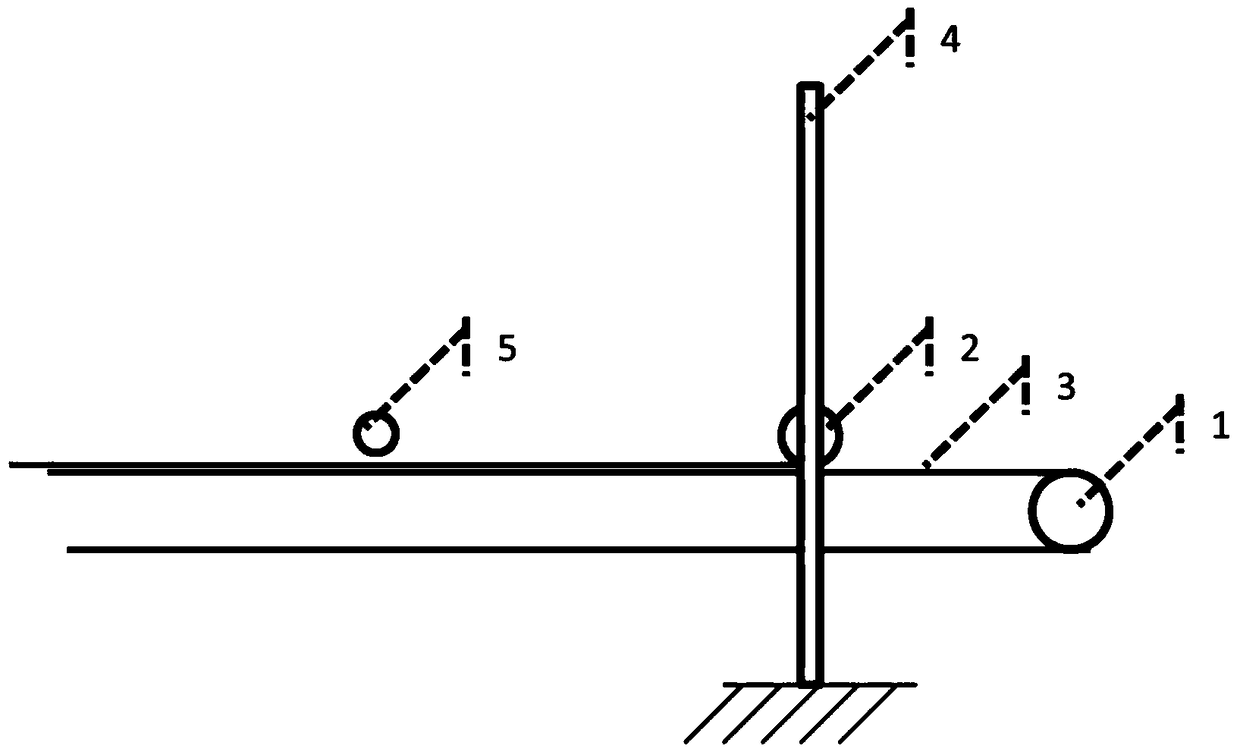

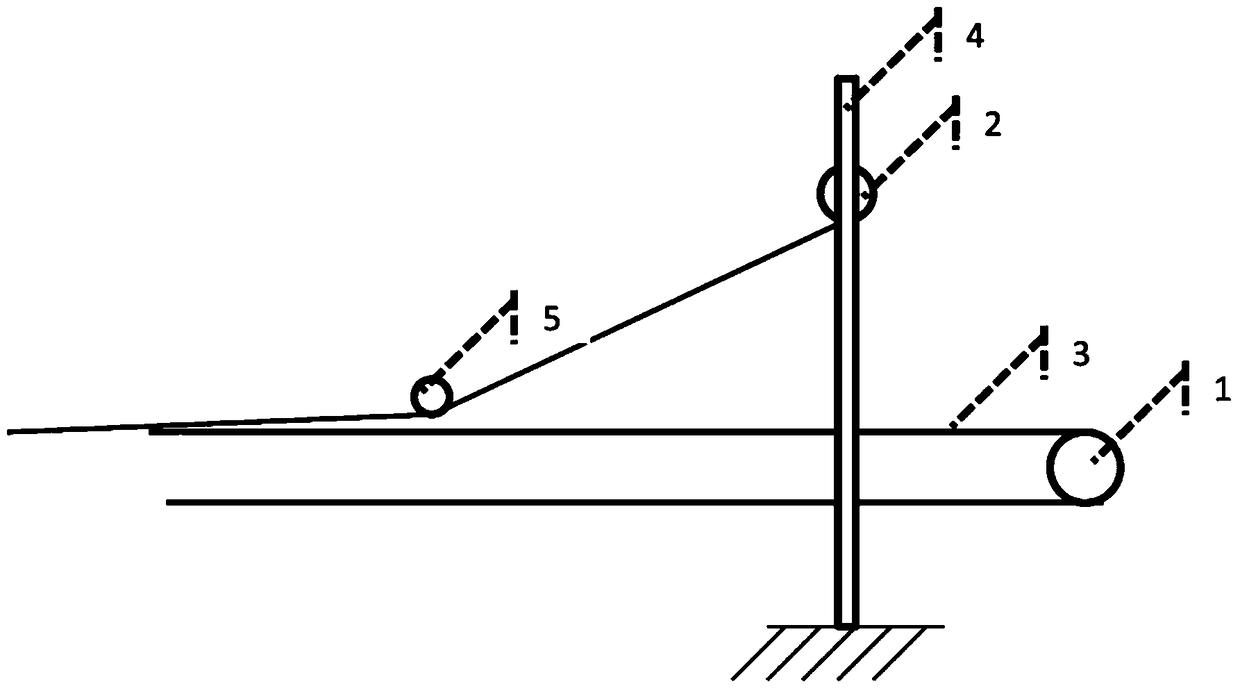

[0014] figure 1 The first step of a method according to the invention is shown at a device according to the invention, which depicts the initial phase of the rolling-up process. In the initial stage, the device or the winding machine works as a circumferential winding machine, whose winding receiver 2 (which can also be called sleeve 2 or winding station 2) rests on a conveyor belt 3 in such a way that it can Winding is performed automatically. The disadvantage of this circumferential winding machine is that the reel, that is to say the product already rolled up on the winding receiver 2, rests against the conveyor belt 3 under its own weight, so that by reciprocating work on the product already rolled up deformation or surface damage may occur. To avoid this, the winding position is lifted by a second drive directly after the start phase, ie after the few turns have been generated, which can be a linear drive or a hydraulic cylinder or a pneumatic cylinder or Electric cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com