Roller system scraper for hot galvanizing

A hot-dip galvanizing and scraper technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of fast wear of screw nut structure, affecting normal production, heavy workload, etc. Long service life, good resistance to zinc powder dust, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

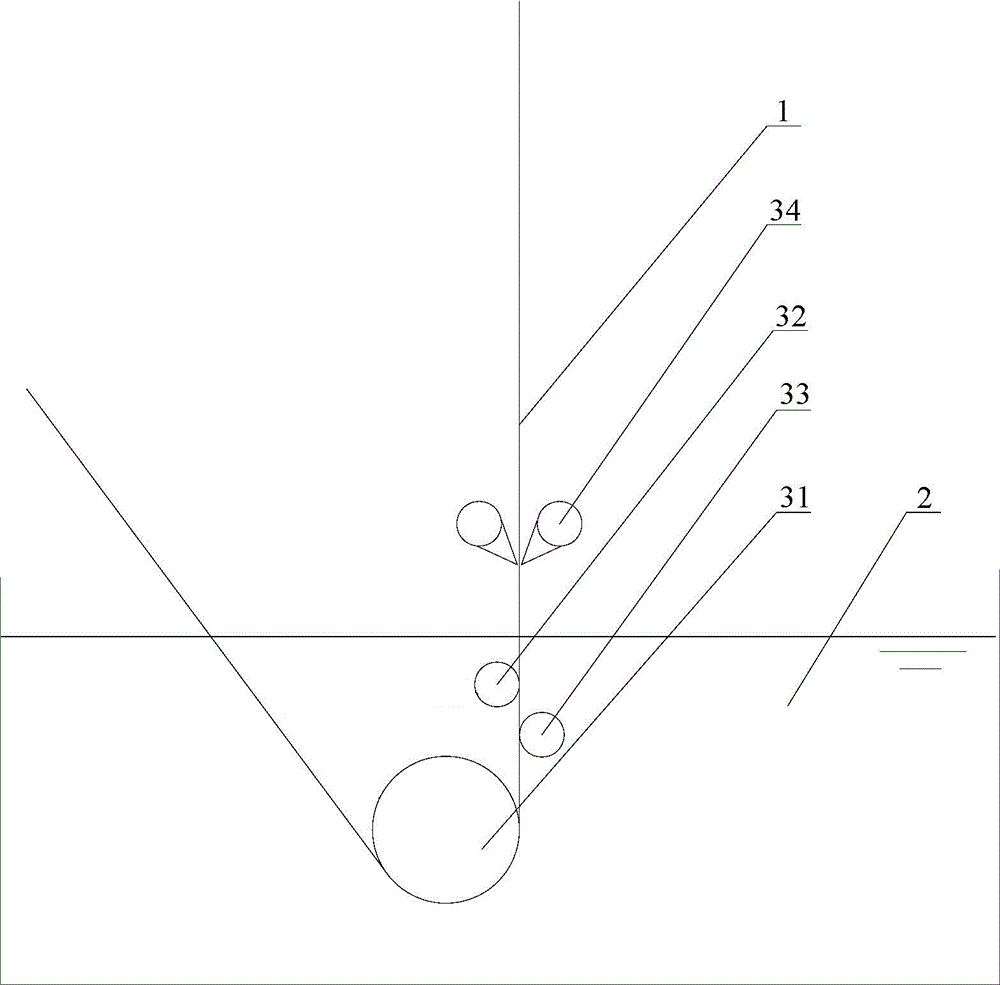

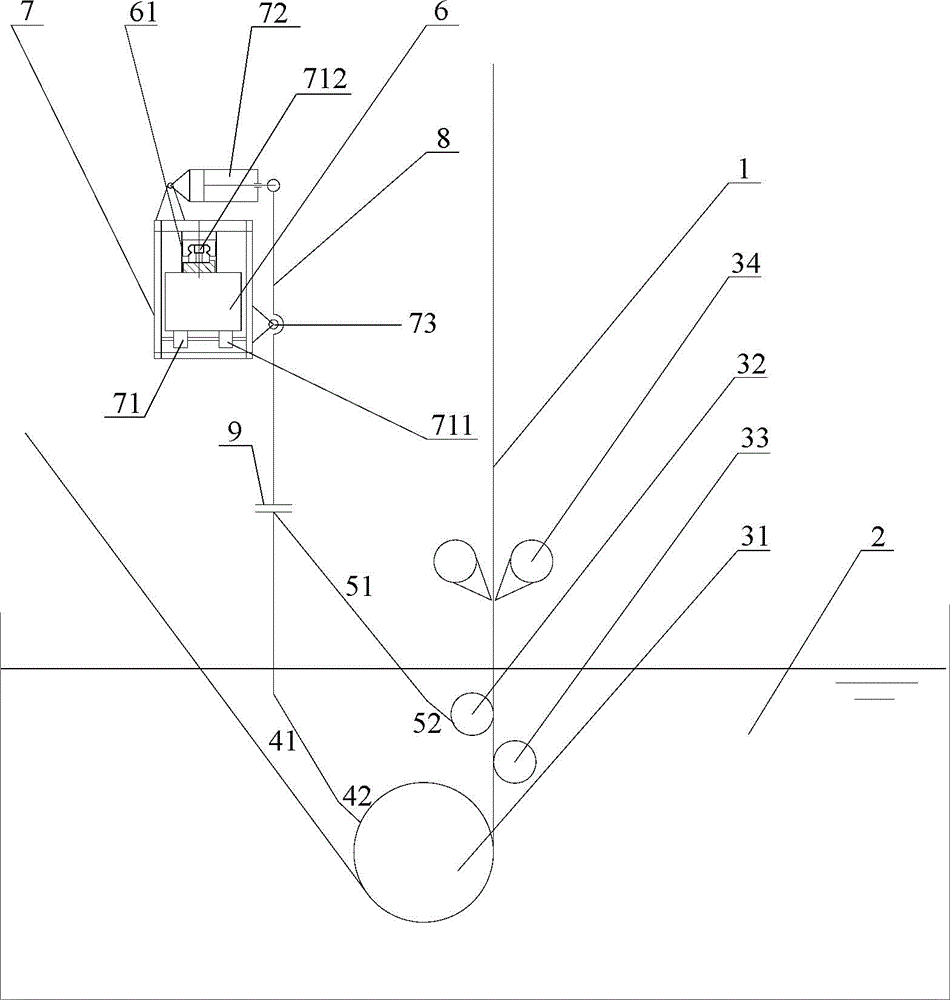

[0028] Such as figure 2 As shown, the steel strip 1 goes deep into the zinc pot 2 after being sent out from the return furnace, and the zinc pot 2 is filled with molten zinc liquid with a temperature as high as 450°C to 600°C, the sinking roll 31, the stabilizing roll 32 and the correction roll 33 and All submerged in the zinc liquid; after the strip steel 1 is immersed in the zinc liquid surface, zinc is adhered to the surface, and then the strip steel 1 is attached to the roller surface of the sinking roller 31 and passed through the zinc liquid surface by the sinking roller 31 turning upward; the zinc liquid surface An air knife 34 is respectively arranged on both sides of the upper strip steel 1, and the blowing ports of the air knife 34 are respectively facing one surface of the strip steel 1, and the zinc pot 2 is provided with a stabilizing roller 32 and a correcting roller 33, and the stabilizing roller 32 and the correcting roller The rollers 33 are arranged on both ...

Embodiment 2

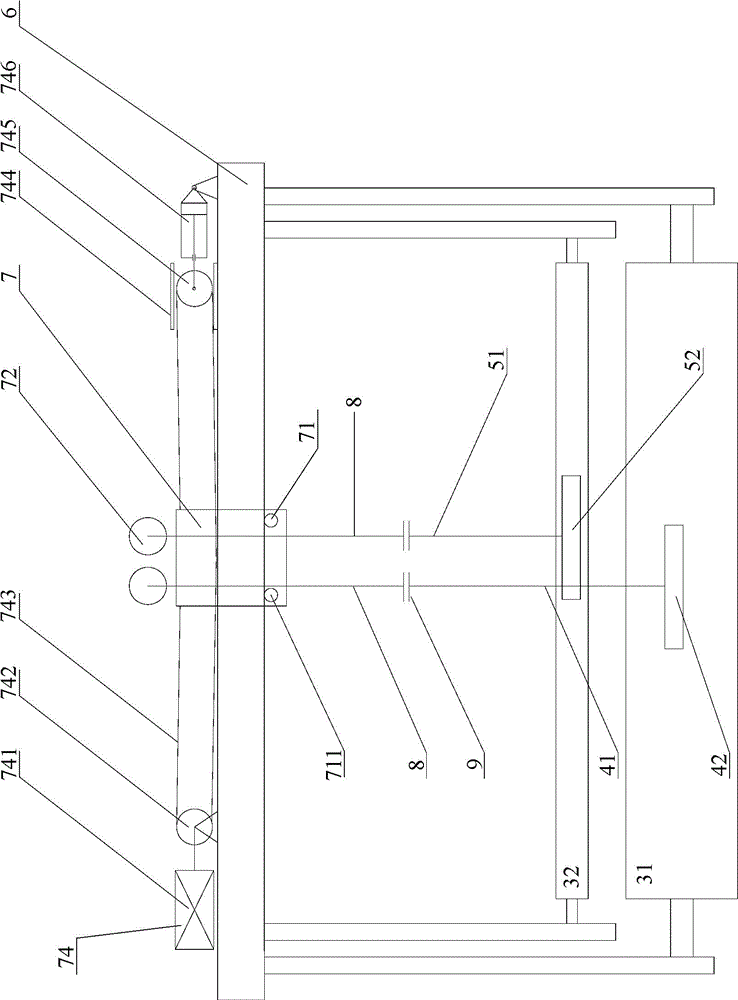

[0042] A roller scraper for hot-dip galvanizing, including a sinking roller scraper arm 41, a sinking roller scraper blade 42, a stabilizing roller scraper arm 51, a stabilizing roller scraper blade 52, a beam 6, a linear guide rail 61, a moving trolley 7, and a traveling mechanism 71, telescoping mechanism 72, hinge point 73, reciprocating propulsion mechanism 74, scraper lever 8 and flange 9, such as Figure 4 Shown, concrete structure is: reciprocating propulsion mechanism 74 selects propelling cylinder 747 for use, and the outer end of propelling cylinder 747 piston rods is the reciprocating propelling end of reciprocating propulsion mechanism 74, drives mobile dolly 7 along linear guide rail 61 by the expansion and contraction of propelling cylinder 747 piston rods Move back and forth.

[0043] Other structures and usage methods are all the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com