Melt spinning device used for jacquard fabric

A melt spinning and jacquard technology, applied in the field of spinning machinery, can solve the problems of easy entry of impurities, affecting the production efficiency and production quality of synthetic jacquard fabrics, slow cooling effect, etc., and achieves good cooling effect and good application prospect. , fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

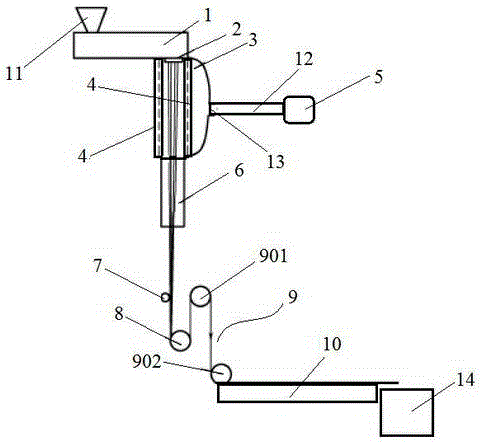

[0016] Such as figure 1 As shown, a melt spinning device for jacquard fabrics includes a screw extruder 1, a spinneret 2, a blower window 3, a cooling water curtain 4, a blower 5, a spinning shaft 6, and an oil pan 7 , godet 8, wire winding mechanism 9 and wire feeding platform 10, one side of the upper part of the screw extruder 1 is provided with a feeding bin 11, the feeding bin 11 is an inverted conical shape, which is convenient for placing fiber raw materials, The spinneret 2 is arranged at the discharge port of the screw extruder 1, the blowing window 3 is located directly below the discharge port of the screw extruder 1, and the two sides of the blowing window 3 are respectively provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com