A construction structure and method for lateral expansion of a large-span cavern based on a narrow underground passage

A technology of underground passages and construction methods, which is applied to underground chambers, earth drilling, mining equipment, etc., can solve problems such as slow construction progress and limited transportation organization, and achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

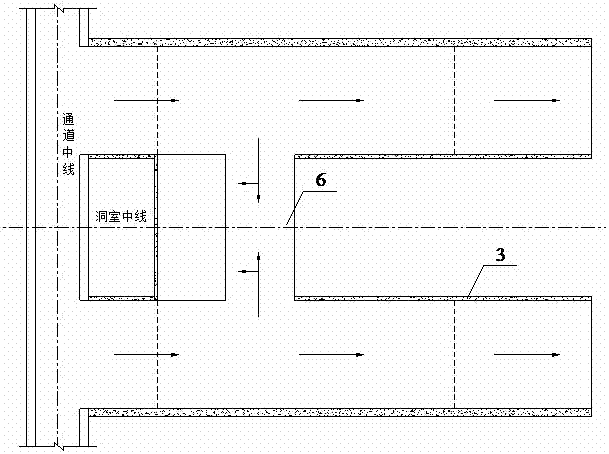

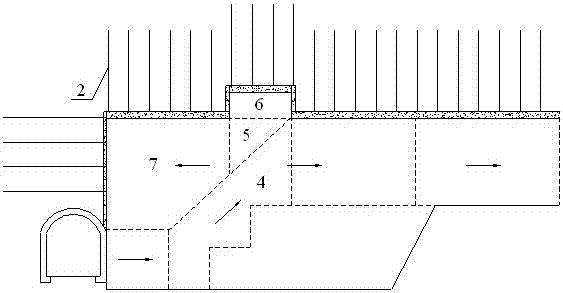

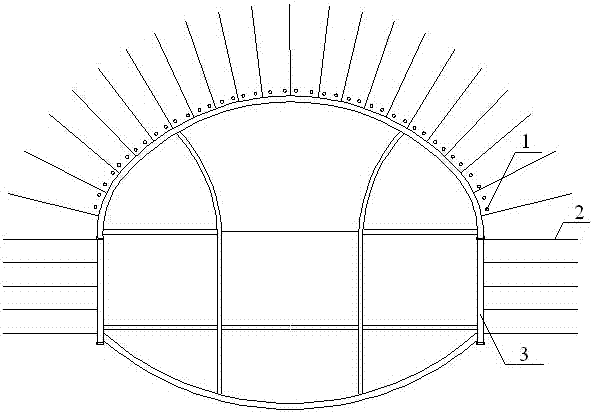

[0025] Embodiment 1: as Figure 1-3 As shown, a construction structure based on the lateral expansion of a narrow underground passage to expand a large-span cavern, including an advanced small conduit 1, an anchor rod 2, a supporting steel frame 3, a transition section 4, a triangular soil body 5, and a horizontal communication passage 6, Remaining soil 7;

[0026] The front end of the advanced small conduit 1 is provided with a slurry overflow hole, and the cement slurry is injected before excavation, and is distributed on the vault of the excavation cavern, and the direction is consistent with the excavation direction of the cavern; the anchor rod 2 is inserted into the surrounding rock mass radially along the cavern , the supporting steel frame 3 is set up on both sides of the pilot pit when the bilateral pilot pit is excavated, and the transition section 4 is the step excavation soil mass in the pilot pit on both sides; the triangular soil mass 5 is located above the step ...

Embodiment 2

[0037] Embodiment 2: as Figure 1-3 As shown, a construction structure based on the lateral expansion of a narrow underground passage to expand a large-span cavern, including an advanced small conduit 1, an anchor rod 2, a supporting steel frame 3, a transition section 4, a triangular soil body 5, and a horizontal communication passage 6, Remaining soil 7;

[0038] The front end of the advanced small conduit 1 is provided with a slurry overflow hole, and the cement slurry is injected before excavation, and is distributed on the vault of the excavation cavern, and the direction is consistent with the excavation direction of the cavern; the anchor rod 2 is inserted into the surrounding rock mass radially along the cavern , the supporting steel frame 3 is set up on both sides of the pilot pit when the bilateral pilot pit is excavated, and the transition section 4 is the step excavation soil mass in the pilot pit on both sides; the triangular soil mass 5 is located above the step ...

Embodiment 3

[0048] Embodiment 3: as Figure 1-3 As shown, a construction structure based on the lateral expansion of a narrow underground passage to expand a large-span cavern, including an advanced small conduit 1, an anchor rod 2, a supporting steel frame 3, a transition section 4, a triangular soil body 5, and a horizontal communication passage 6, Remaining soil 7;

[0049] The front end of the advanced small conduit 1 is provided with a slurry overflow hole, and the cement slurry is injected before excavation, and is distributed on the vault of the excavation cavern, and the direction is consistent with the excavation direction of the cavern; the anchor rod 2 is inserted into the surrounding rock mass radially along the cavern , the supporting steel frame 3 is set up on both sides of the pilot pit when the bilateral pilot pit is excavated, and the transition section 4 is the step excavation soil mass in the pilot pit on both sides; the triangular soil mass 5 is located above the step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com