Volume type division engine

A volumetric, engine technology, applied in the field of thermal energy and power, which can solve problems such as inability to change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

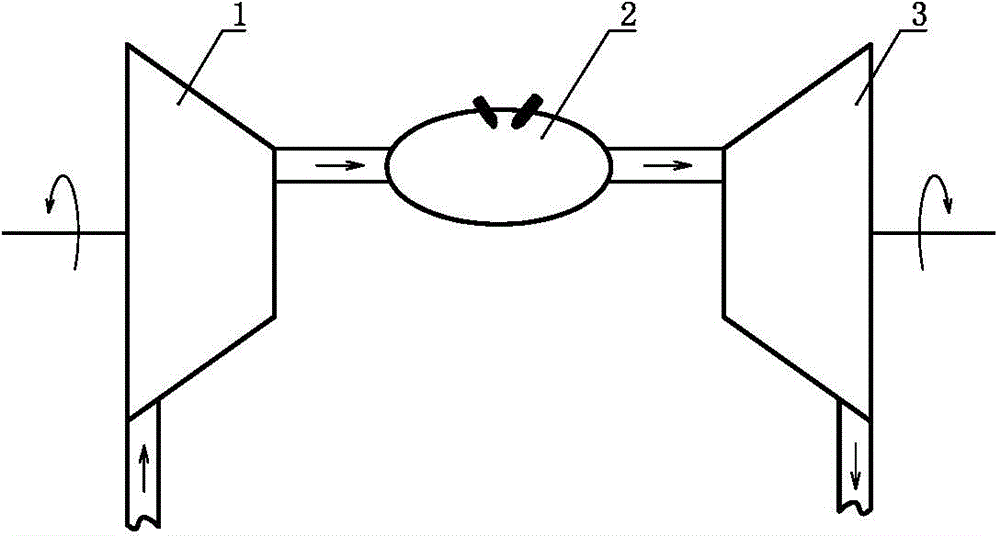

[0050] A volumetric split engine such as figure 1 As shown, it includes a volumetric compression unit 1, an internal combustion combustion chamber 2 and an expansion work unit 3. The volumetric compression unit 1, the internal combustion combustion chamber 2 and the expansion work unit 3 are connected in sequence, and the internal combustion combustion chamber 2 The volume is greater than 1.5 times the single discharge volume of the positive displacement compression unit 1, and the swallowed volume per unit time of the expansion work unit 3 is greater than 1.2 times the discharge volume per unit time of the positive displacement compression unit 1.

[0051] As a changeable embodiment, the volume of the internal combustion chamber 2 can be selectively made greater than 1.6 times, 1.7 times, 1.8 times, 1.9 times, or 2.0 times the single discharge volume of the positive displacement compression unit 1 2.1 times or more, 2.2 times or more, 2.3 times or more, 2.4 times or more, 2.5...

Embodiment 2

[0054] A volumetric split engine comprising Embodiment 1, the volume at the end of the expansion of the expansion work unit 3 discharged per unit time is greater than the volume swallowed per unit time of the volumetric compression unit 1 .

[0055] As a transformable embodiment, on the basis of Embodiment 1 and its transformable embodiment and Embodiment 2, the expansion work unit 3 can be further selectively set as a volume expansion work unit or as a speed type Expansion work unit.

Embodiment 3

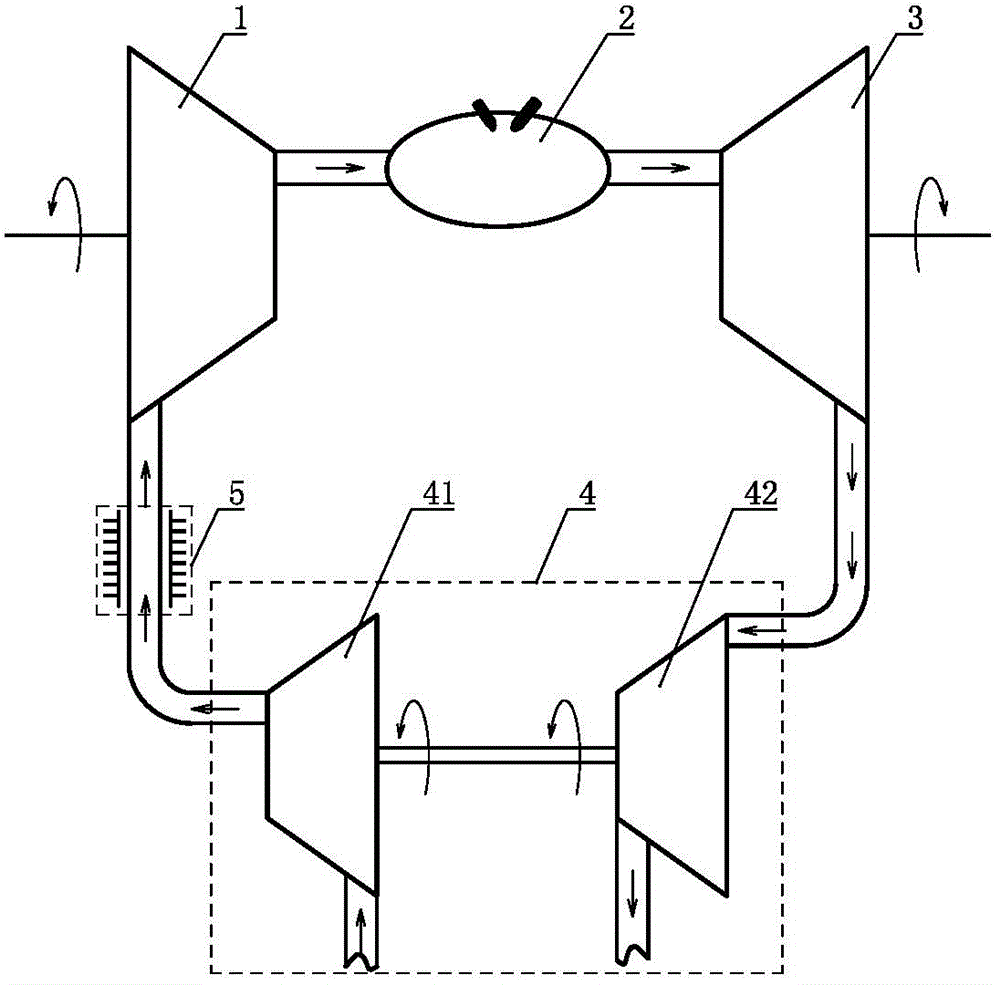

[0057] A kind of displacement type split engine comprising embodiment 1, such as figure 2 As shown, the displacement type split engine also includes a turbocharger 4, the working medium outlet of the compressor 41 of the turbocharger 4 communicates with the working medium inlet of the volumetric compression unit 1, and the turbocharger The working medium inlet of the turbine 42 of the supercharger 4 communicates with the working medium outlet of the expansion work unit 3 , and an intercooler 5 is provided at the working medium outlet of the compressor 41 .

[0058] As a changeable implementation, the changeable implementation of embodiment 1 and embodiment 2 and its changeable implementation can further make the displacement type split engine further include a turbocharger 4, and the turbocharger The working medium outlet of the compressor 41 of the device 4 communicates with the working medium inlet of the volumetric compression unit 1, and the working medium inlet of the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com