Hub motor type self-generating electricity trailer robot

A wheel hub motor and robot technology, which is applied in the fields of vehicles, firefighting, military, lifting, and explosives, can solve the problems of delayed disaster relief, folding effect, high center of gravity, etc., and achieve the effect of improving safety and braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

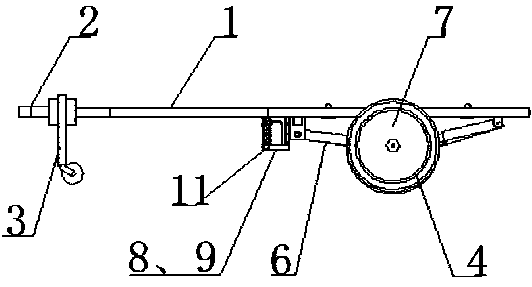

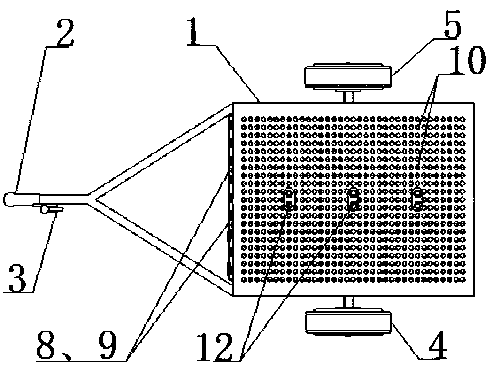

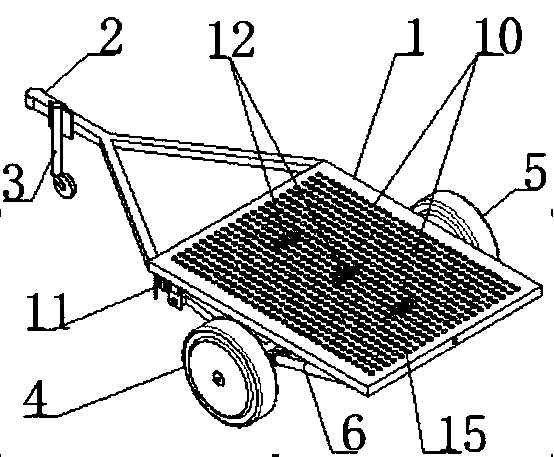

[0039] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a hub motor type self-generating trailer robot, the front end of the trailer bracket 1 is provided with a trailer connector 2 and a wheeled trailer jack 3; the trailer connector 2 can be a small hook, and the wheeled trailer jack 3 can be universal wheel. The left wheel 4 and the right wheel 5 are respectively connected to both sides of the trailer support 1 through the suspension 6; Left wheel 4, right wheel 5 are arranged in pairs, can be a pair, two pairs, or more than two pairs.

[0040] The left wheel 4 and the right wheel 5 are connected with the hub motor 7; the hub motor 7 is connected with a motor driver and an MTTP power generation controller through a switching relay, and the motor driver is connected with a robot controller; when the switching relay is not powered on, the power motor and the MTTP The power generation controller is connected; when the switching relay is powered on, the power mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com