Connecting and laying method capable of prolonging service life of PEX pipe

A laying method and pipe fitting technology, applied in the field of PEX pipe fittings, can solve problems such as water leakage at joints, affecting the service life of PEX pipe fittings, aging, etc., and achieve the effects of improving firmness, increasing service life, and preventing aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention

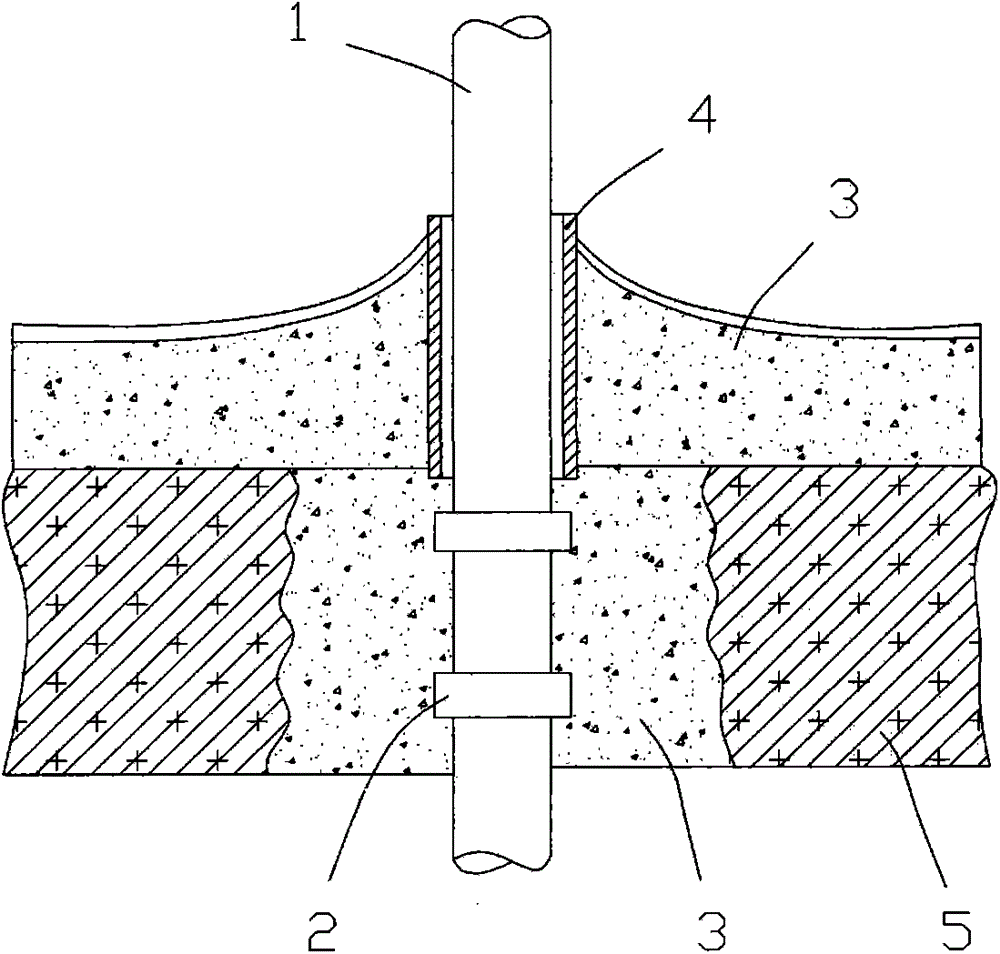

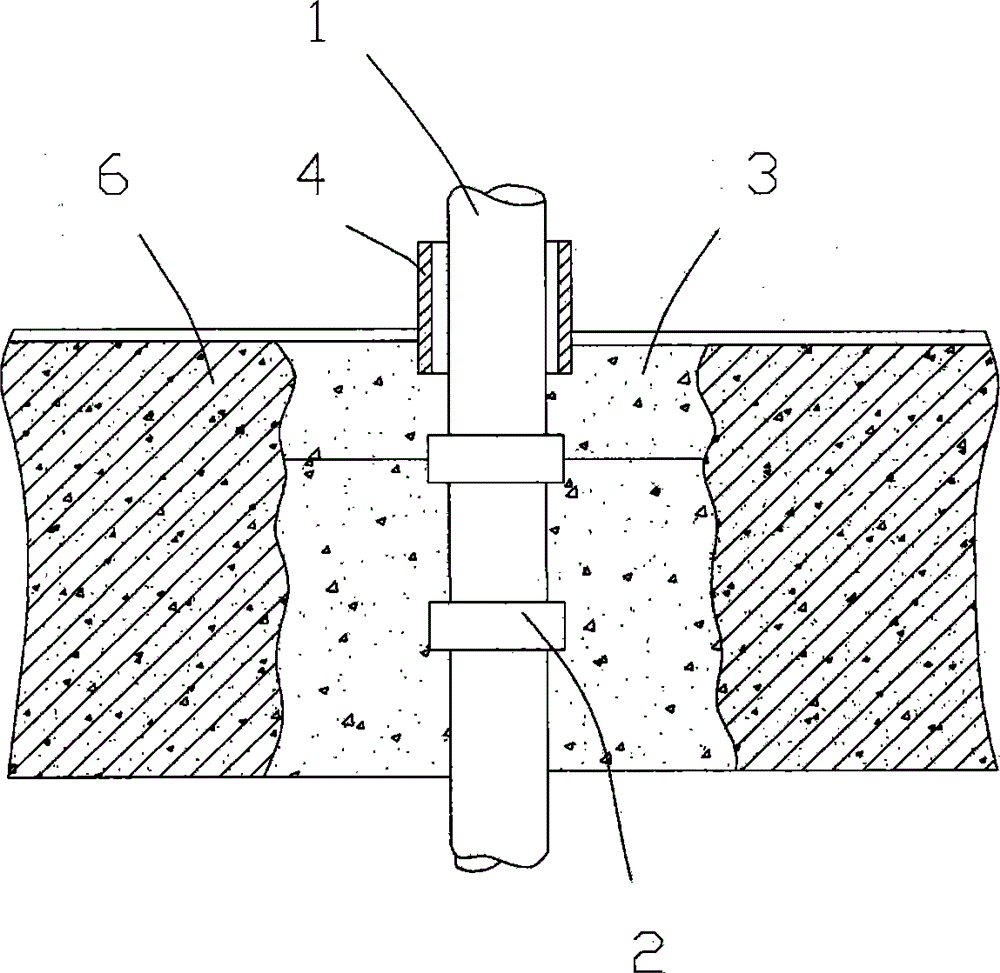

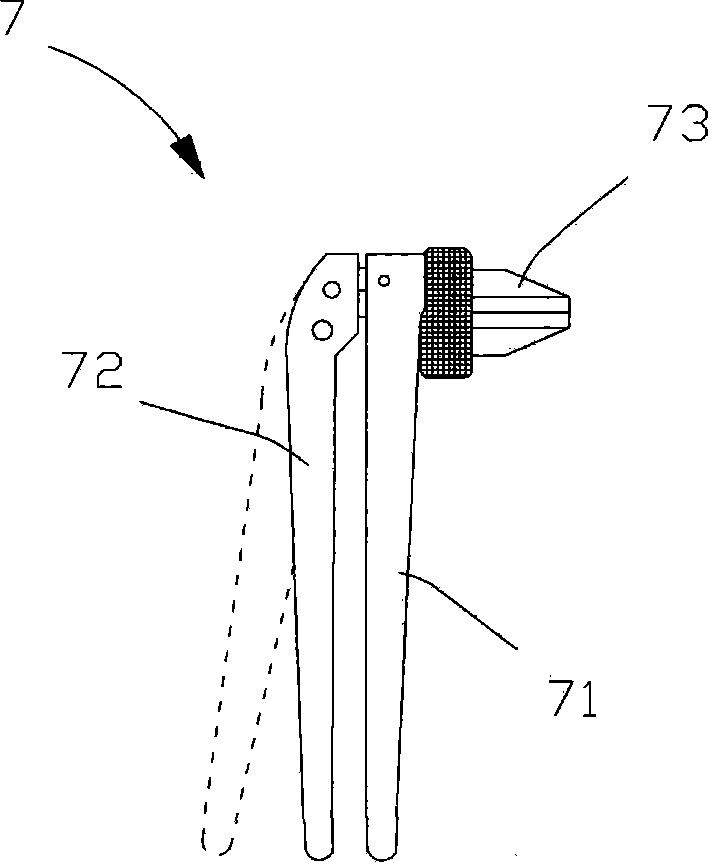

[0022] An embodiment of a connection and laying method that can prolong the service life of PEX pipe fittings of the present invention comprises the following steps: (1) placing the clamping ring on the PEX pipe fittings; (2) expanding one end of the PEX pipe fittings with a mouth expander (3) Insert another PEX pipe fitting from the flaring end of the PEX pipe fitting; (4) Clamp the clamping ring so that the two PEX pipe fittings fit together; (5) Lay the pipe through the wall time like figure 1 As shown, a perforation is first opened on the wall surface 5, and then the PEX pipe fitting 1 is placed in the perforation, and the copper ring 2 is fixed and clamped on the PEX pipe fitting section located in the perforation. Specifically in this embodiment, the PEX pipe fitting section Two cla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap